10 long term storage preparation, 11 boom lubrication points – SkyTrak 6036 Service Manual User Manual

Page 31

Section 3

Boom

Model 6036/6036T S/N 9B0500 thru 14833

3-13

A

B

A

A

D

OA0182

C A A

B (FIG. 3.13)

3.1.10 Long Term Storage Preparation

Remove rust and corrosion from sliding surfaces

and coat with grease.

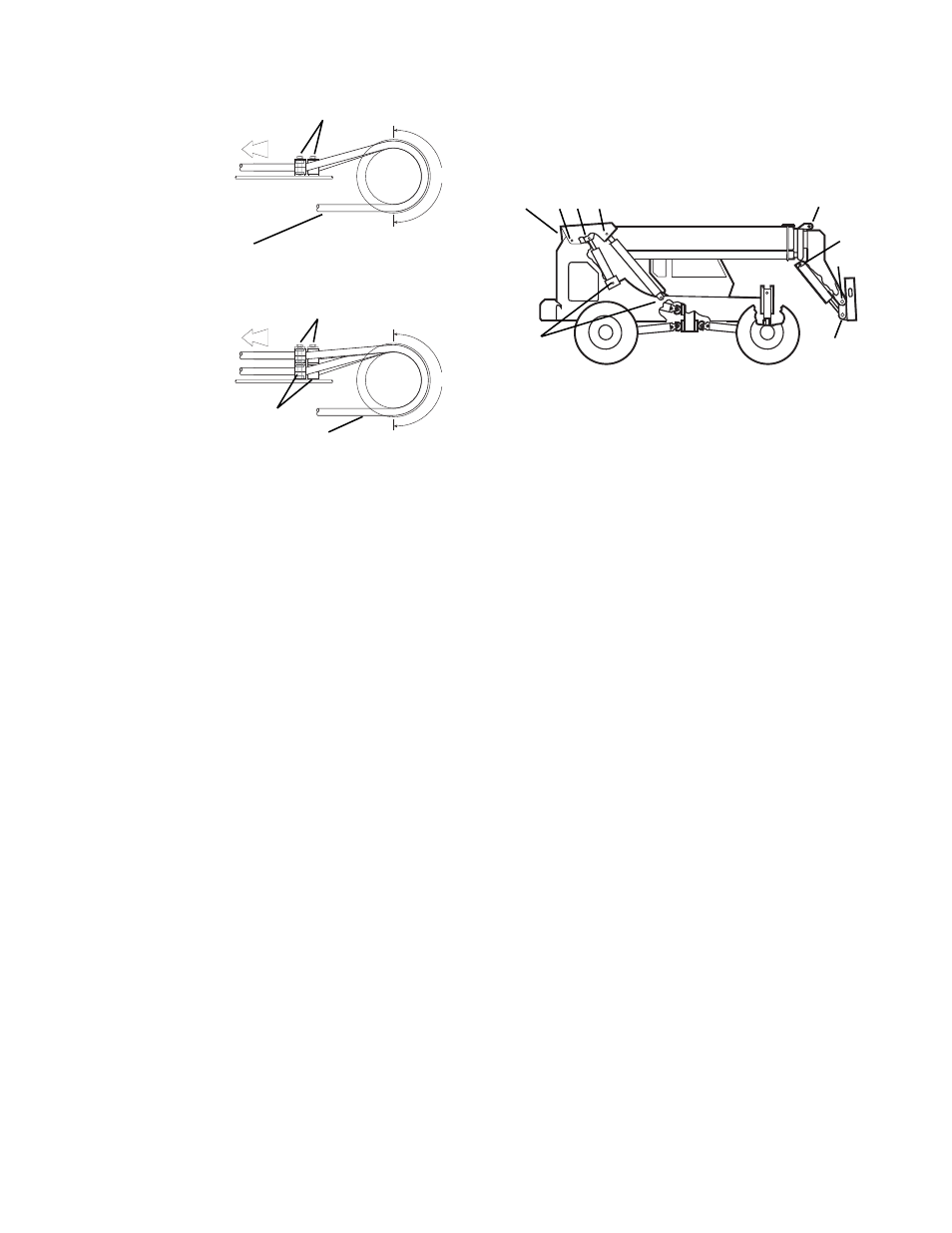

Fig. 3.18 Forklift Lubrication Points

3.1.11 Boom Lubrication Points

Lubricate the following grease fittings using Multi-

Purpose Grease (MPG) every 50 hours. Refer to

Fig. 3.18.

A. Hydraulic cylinder pins (8 points)

B. Boom chain sheaves (2 points)

C. Boom pivot pins (2 points)

D. Carriage pivot pin (2 points)

Lubricate the boom extend and retract chains

using Aerosol .0002 Waxy Film Rust Inhibitor,

TRAK part number 8526405 every 250 hours.

1.

Prepare to grease the chains by removing the

rear cover from the outer boom.

2.

Apply MPG to retract chain using a brush or

grease gun.

3.

Extend and retract the boom several times to

permit grease to penetrate the entire chain.

4.

With the boom extended fully, apply MPG to

the extend chain using a brush or grease gun.

5.

Replace the rear outer boom cover.

6.

Pull the hoses 1" further into the hose clamps

so the hose achieves more than 180° of

contact with the pulley and at the same time

tighten the clamp capscrews.

7.

If the vehicle has auxilliary hydraulics, replace

the upper hoses and clamps onto the lower

hose clamps. Do not fully tighten the cap-

screws. Repeat steps 4 through 6 for the

upper hoses and clamps.

8.

Replace the rear boom cover.

180

°

180

°

MA6050

Hose must have a

minimum of 180° of

contact with pulley

Upper set of hose

clamps and capscrews

Pull hoses, through hose

clamps, 1" further to

tension hoses

When vehicle has auxilliary hydraulics option, remove

upper clamps in stack and tension lower hoses first and

then tension top hoses

Inner boom hose

clamps and capscrews

Lower set of hose clamps

and stacking capscrews

Pull hoses, through hose

clamps, 1" further to

tension hoses

Hose must have a minimum of

180° of contact with pulley

Fig. 3.17a Cylinder Hose Tensioning

MA6040

Fig. 3.17b Cylinder Hose Tensioning