10 fluid levels and lubrication, 10 after axle servicing, 1 wheel ends – SkyTrak 6036 Service Manual User Manual

Page 16

Section 2

General Instructions

2-6

6036/6036T S/N 9B0500 thru 14833

2.9.10 After Axle Servicing

1.

Check fluid levels.

2.

Check torque of drive shaft yoke hardware.

3.

Check wheel nut torque.

4.

Check toe-in if required.

5.

Lubricate all grease points.

6.

Refer to Dana Service Manual for “SECTION

1 - General Information”.

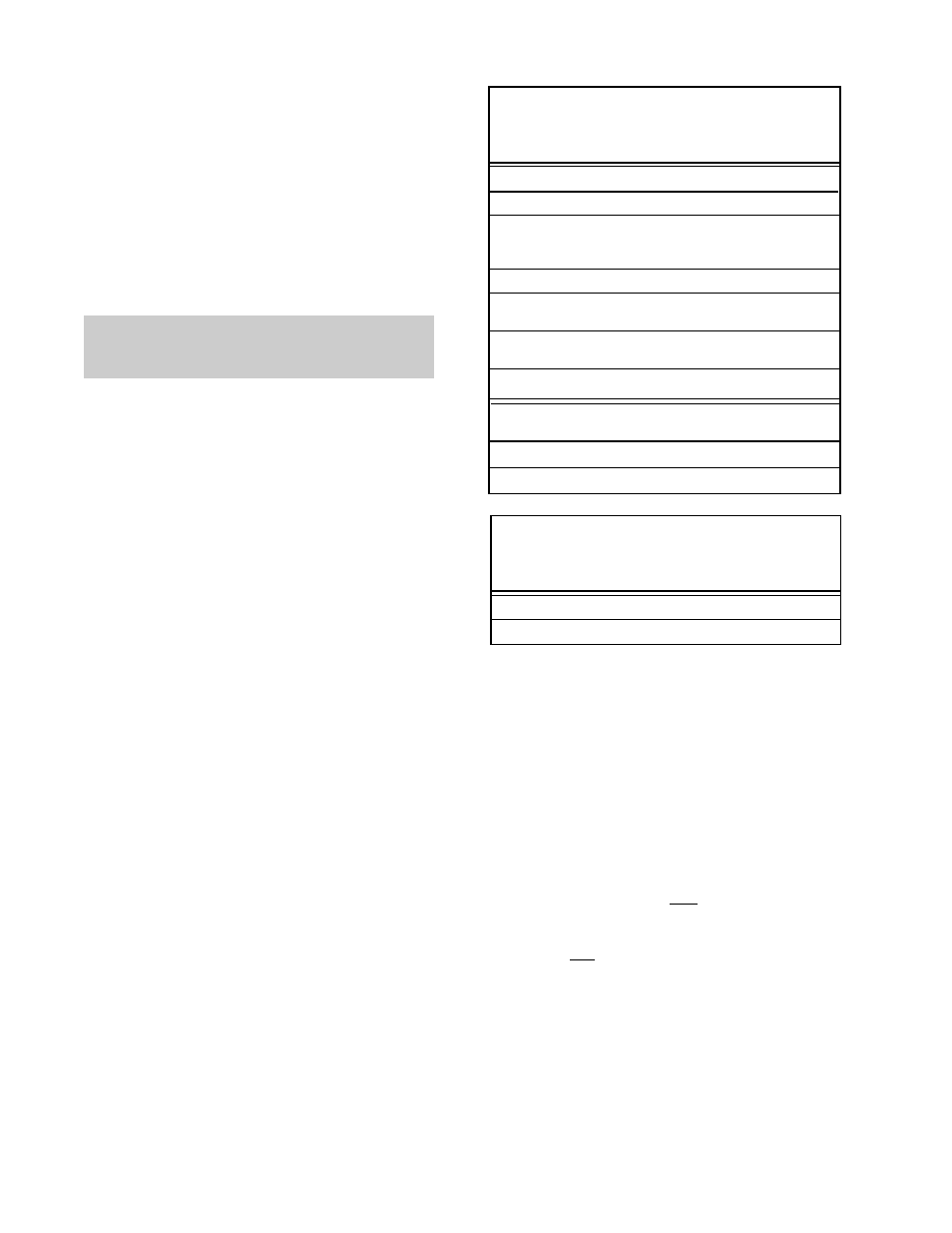

TABLE 1

Recommended oils for DANA SPICER

®

axles

P/N 070BP126-13 (front axle) and

070BP139-2 (rear axle) w/graphite based friction discs.

BRAND

DESCRIPTION

Amoco

Amoco 1000

Case IH

MS-1207 (Hy-Tran

®

Plus)

(J.I. Case & International

MS-1210/JIC145 (TCH Fluid)

Harvester)

John Deere

JDM J20C (Hy-Gard

®

)

Ford-New Holland

ESN-M2C134-D

(Hydraulic Oil 134)

Massey-Ferguson

M-1141 (Permatran

®

III)

M-1135 Massey-Ferguson

Mobil

424

FRICTION MODIFIER

PART NUMBER

BRAND

TRAK

8522043 (32 oz)

Ford

C8AZ19B546A (4 oz)

TABLE 2

Recommended oil for DANA SPICER

®

axles

P/N 070BP126-2 (front axle) and

070BP139-1 (rear axle) with paper based friction discs.

OIL BRAND

PART NUMBER

TRAK Wet Disc Brake Oil

8522042

2.10 FLUID LEVELS

AND LUBRICATION

2.10.1

Wheel Ends

Use the following procedure to check fluid level on

the wheel ends:

1.

Be sure that arrow on the wheel end housing

is pointing down. Level the vehicle, ground

the carriage, place the travel select lever in (N)

Neutral, engage the emergency brake switch

and shut off engine.

2.

Clean the area around the magnetic drain plug

and remove the plug and check fluid level.

Add oil (refer to “IMPORTANT” statement and

tables on this page) as required to bring level

up even with the plug hole (for temperatures

below -15° F (-26° C) 75W gear oil can be

used).

3.

Clean and install drain plug.

IMPORTANT: All wheel ends are factory filled

with oil that contains friction modifier. DO NOT

add additional friction modifier to factory filled

wheel ends. The addition of friction modifier to a

factory fill will dilute the properties of the oil and

can reduce braking ability.

To assure a quiet brake condition when servicing

wheel end oil, use only recommended oils as

defined in Table 1 or Table 2 above.

If a noisy brake condition exists after a fresh fill

from oils listed in Table 1 only, add 6 ozs.

(0,18 ltr) of friction modifier per wheel end.

NEVER add more than 6 ozs. (0,18 ltr) of friction

modifier to any wheel end as too much modifier

can reduce braking ability.

NEVER add friction modifier to the recommended

oil listed in Table 2. This oil already contains

friction modifier and additional friction modifier

can reduce braking ability.