SkyTrak 6036 Service Manual User Manual

Page 291

Section 10.

Electrical System

10-29

Model 6036/6036T S/N 9B0500 thru 14833

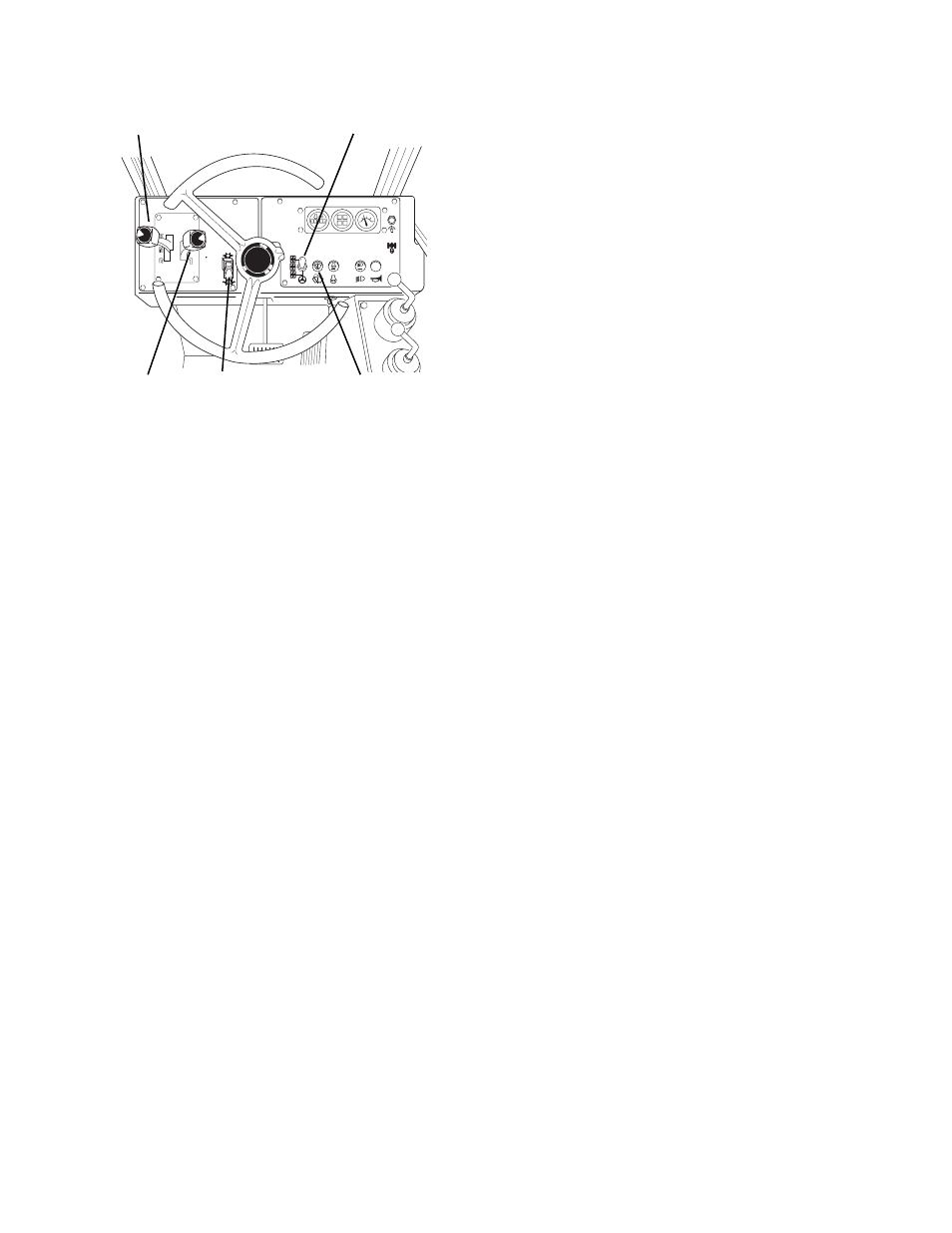

EMERGENCY

BRAKE

P

P

TRAVEL

SELECT

LEVER

STEERING

SELECT

SWITCH

PARK

LOCK

SWITCH

RANGE

SELECT

LEVER

Fig. 10.21 Control Panel

WINDSHIELD

WASHER/WIPER

CONTROL

OH0043

a.

Removal

1.

Engage the park lock, place the travel select

lever in neutral, and turn the ignition switch to

OFF.

2.

Disconnect negative (–) cable (2, Fig. 10.16)

from the batteries.

3.

Unlock and open the right engine access door

to gain access to the fuel injection pump.

4.

Tag and remove electric wires or pull electrical

connector apart for S/N 3617 & after turbo

engines.

5.

A plunger and spring may fall from the sole-

noid when it is removed from the fuel injection

pump except for S/N 3617 & after turbo

engines see step 6. Be prepared to catch

these parts when you remove the solenoid.

Use an appropriate wrench to turn the sole-

noid counterclockwise.

6.

S/N 3617 & after turbo remove the solenoid

from the backside of the injector pump by

removing the two bolts holding the solenoid to

the mounting plate. Remove the nut holding

the linkage to the arm on the pump. Save all

the hardware for reassembly.

7.

Discard the O-ring.

b. Disassembly

Do not disassemble the fuel run solenoid.

c.

Cleaning and Drying

Without submerging the electrical components,

clean the fuel run solenoid using a approved

solvent and dry using a clean lint-free cloth.

d. Inspection and Replacement

1.

Prepare to test the fuel run solenoid by

assembling the valve at a bench.

2.

Energize the solenoid using 12 Vdc to see if

the plunger retracts. Replace fuel run sole-

noid if it doesn’t retract.

e.

Installation

1.

Clean exterior of fuel injection pump.

2.

Install a new O-ring on the fuel run solenoid.

3.

Remove protective plug from fuel injection

pump.

4.

With spring and plunger in solenoid, turn fuel

run solenoid into fuel injection pump, being

careful to avoid cross threading. Tighten until

snug. S/N 3617 & after turbo see step 5.

5.

S/N 3617 & after turbo line up the holes in the

solenoid with the holes in the mounting plate

and secure in place with the two bolts. As-

semble the linkage end of the solenoid to the

arm on the injector pump with the hex nut.

Tighten all hardware securely.

6.

Connect electric wires and connect negative

cable to batteries.

7.

Close and lock the engine access door.

8.

Prepare to test fuel run solenoid by clearing

personnel and any obstructions from the area

around the forklift.

9.

Start the engine.

• If engine starts the solenoid is functioning.

• If engine fails to start, solenoid may have

a poor ground connection. Check voltage

at solenoid.

10. Check for fuel oil leakage around solenoid.