Warning – SkyTrak 6036 Service Manual User Manual

Page 154

Section 9

Hydraulic System

9-4

Model 6036/6036T S/N 9B0500 thru 14833

c.

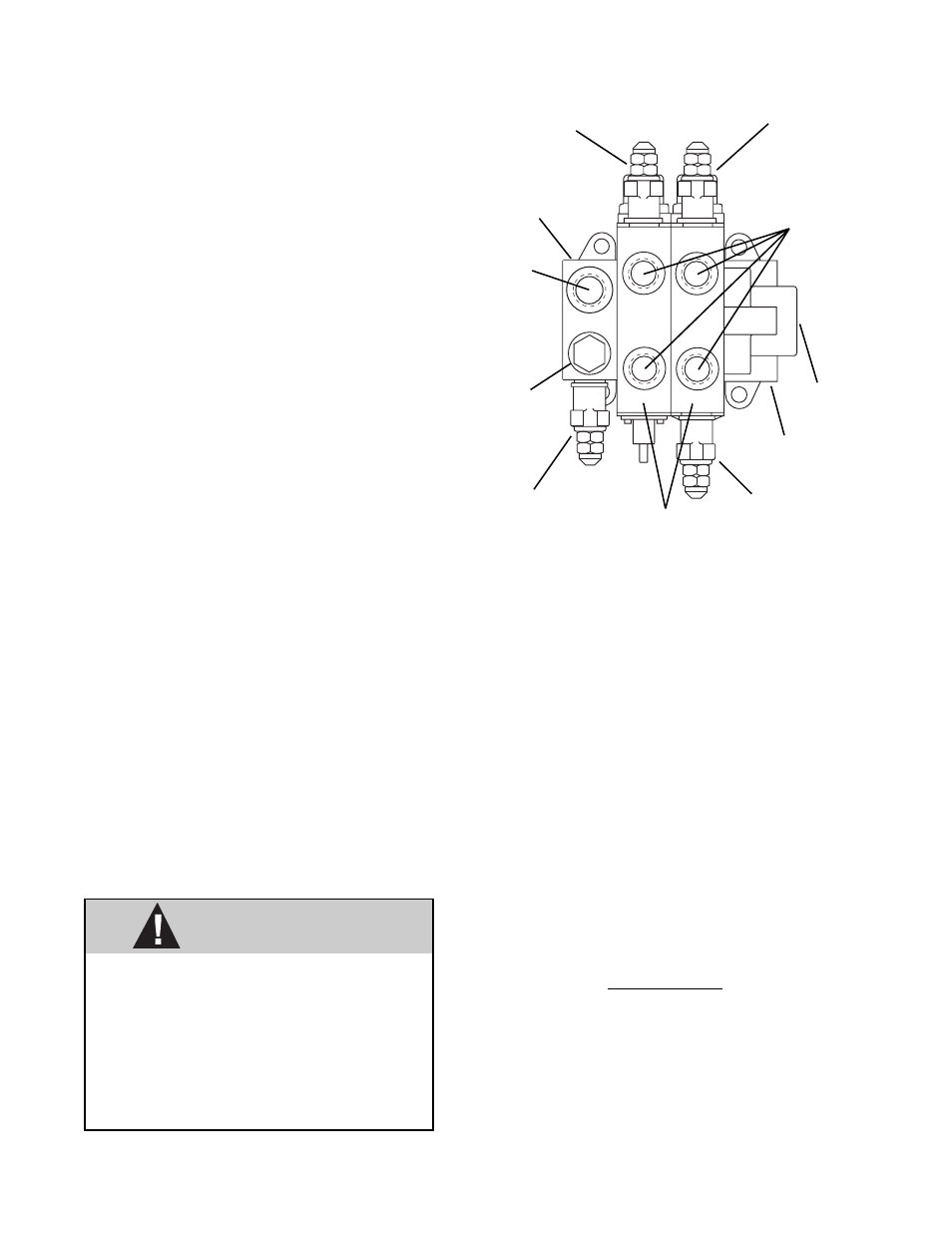

Working Sections

There are two parallel working sections of the

control valve, Fig. 9.2, one for controlling the boom

raise/lower function and one for controlling the

boom extend/retract function, Fig. 9.3.

The boom raise/lower working section contains:

•

A spring centered spool that is shifted by

the operator joystick and its associated

cable that directs the hydraulic oil. Func-

tion and operation of the spool is ex-

plained in the raise/lower circuit, para-

graph 9.2.2.

•

A load-drop check valve to prevent a load

from dropping when the operating spool is

shifted.

•

Two work ports that allow the hydraulic oil

to flow to and from the cylinders.

•

One port relief valve, set at 2850 ± 50 psi

(196,4 ± 3,4 bar). Function of the relief

valve is explained in the boom raise/lower

circuit, paragraph 9.2.2. Operation of the

valve is explained in paragraph 9.2.1.b.

The boom extend/retract working section contains:

•

A spring centered spool that is shifted by

the operator joystick and its associated

cable that directs the hydraulic oil. Func-

tion and operation of the spool is ex-

plained in the extend/retract circuit,

paragraph 9.2.3.

•

A load-drop check valve to prevent a load

from dropping when the operating spool is

shifted.

•

Two work ports that allow the hydraulic oil

to flow to and from the cylinders.

•

Two port relief valves, set at 2850 ± 50 psi

(196,4 ± 3,4 bar). Function of the relief

valves is explained in the boom extend/

retract circuit, paragraph 9.2.3. Operation

of the valves is explained in paragraph

9.2.1.b.

Warning

• If anyone is injured by or if any hydraulic fluid

is injected into the skin, obtain medical

attention immediately or gangrene may

result.

• Wear appropriate eye protection. Hydraulic

fluid can cause permanent eye injury. Do

not wear loose fitting clothing when servicing

the forklift.

MAIN

RELIEF

VALVE

WORK

PORTS

INLET

PORT

OUTLET

PORT

BOOM

RETRACT

PORT

RELIEF

VALVE

BOOM RAISE

PORT RELIEF

VALVE

INLET

SECTION

OUTLET

SECTION

PARALLEL

WORKING

SECTIONS

PLUG

MA2090

d. Outlet Section

The outlet section is an end cover where the outlet

port is located on the side of the cover, Fig. 9.3.

9.2.2

Boom Raise/Lower Circuit

a.

Description

Hydraulic pressure is applied in the boom raise/

lower circuit by the 30 gpm section (rear half) of

the tandem pump, which draws its fluid through a

suction strainer in the reservoir, Fig. 9.4. Supply

pressure is directed to either side of the right and

left boom hoist cylinder pistons, by the shifting of a

spool in a directional control valve found in the

main control valve assembly. The spool is shifted

by the operator joystick and its associated

control cable. The joystick positions for raising

and lowering the boom are as follows:

Center Position

When the joystick is placed in the center or neutral

position, the directional control valve spool is

positioned so that supply pressure is directed

through ports F to C, Fig. 9.4, to the return filter

and reservoir, Fig. 9.4. If the filter becomes

clogged, hydraulic oil will bypass the filter when

the pressure reaches 10 to 15 psi

(0,69 to 1,03

bar).

Fig. 9.3 Main Control Valve (Cable Control)

BOOM EXTEND

PORT RELIEF

VALVE