Warning – SkyTrak 6036 Service Manual User Manual

Page 223

Section 9

Hydraulic System

Model 6036/6036T S/N 9B0500 thru 14833

9-73

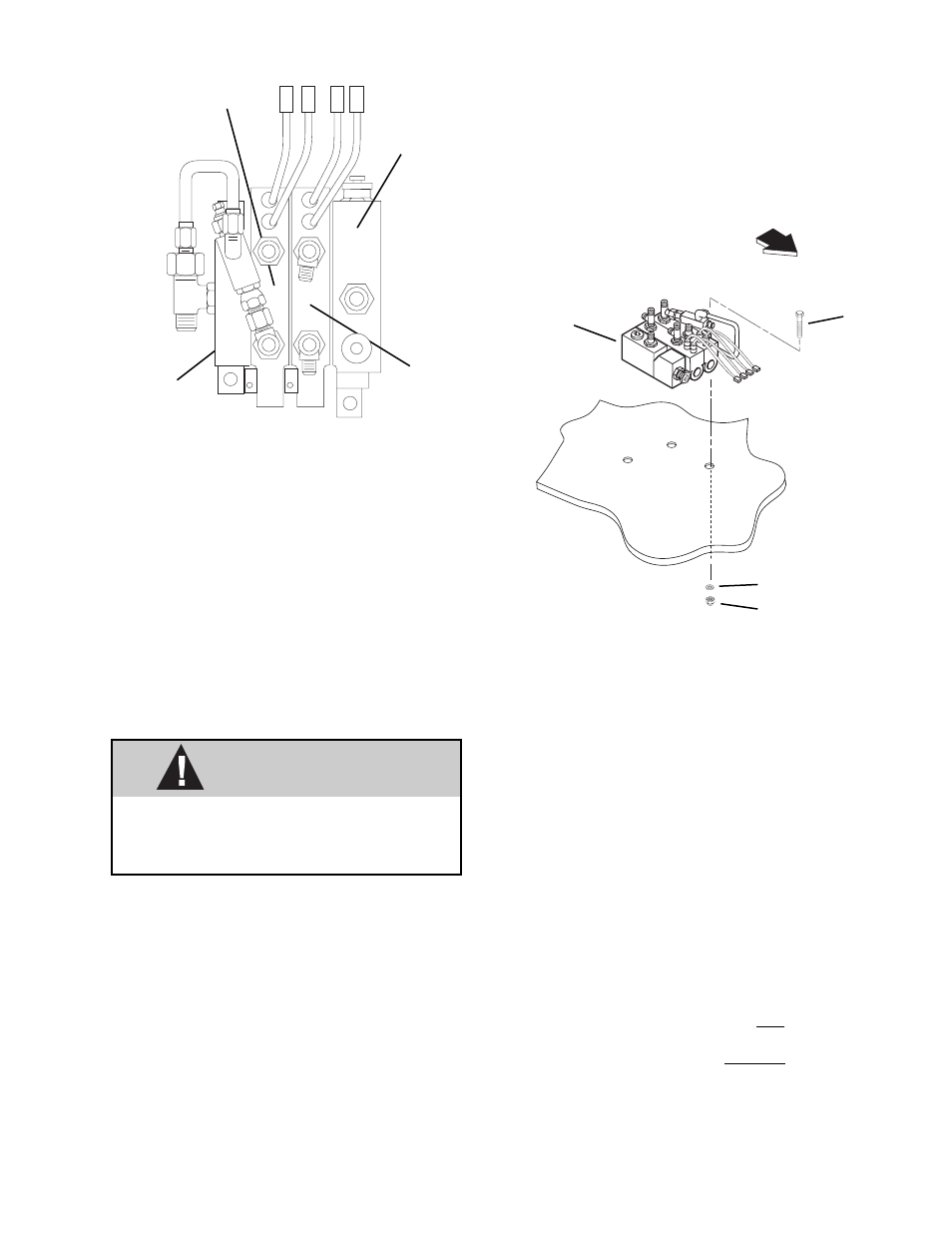

INLET

SECTION

OUTLET

SECTION

EXTEND/RETRACT

SECTION

RAISE/

LOWER

SECTION

4.

Remove the capscrews (1, Fig. 9.42), nuts (2)

and lock washers (3) securing the control

valve to the frame. Remove the control valve

(4) from the forklift to a clean work area. Wipe

the exterior of the valve using a clean cloth

and an approved cleaning solvent such as

trichlorethylene.

2.

Operate the control valve manually by

threading a 3/8 NC x 2" long capscrew into

the spool shift collar of each hydraulic

function, Fig. 9.46. Actuate all of the

hydraulic functions (boom raise/lower,

extend/retract) after the engine has

stopped to relieve any trapped pressure.

3.

Remove dirt and grease from the hydraulic

lines and fittings and control valve using a

clean cloth and an approved cleaning solvent

such as trichlorethylene. Tag and disconnect

the hydraulic lines from the control valve and

cap or plug all connections to prevent system

contamination.

Fig. 9.41 Main Control Valve (Electronic Control)

a.

Removal of Control Valve

NOTE: The following procedures are for out of

warranty service of the valve only. If the valve is

still under warranty it must be replaced as a

complete assembly.

The valve is mounted in the frame at vehicle

center line, to the right behind the cab, Fig. 9.41.

1.

Park forklift on a level surface and engage

parking brake. Retract the boom and support

it in a horizontal position with blocking. Place

travel select lever in neutral and stop the

engine. Be sure the forklift is in a secure

position before servicing.

Warning

Relieve hydraulic pressure before servicing any

hydraulic component. Escaping hydraulic fluid

under pressure can penetrate the skin causing

serious injury.

b. Disassembly of Control Valve Into Sections

NOTE: The following procedures are for out of

warranty service of the valve only. If the valve is

still under warranty it must be replaced as a

complete assembly. Disassemble only to the

extent necessary to replace defective parts.

1.

Remove all fittings, Fig. 9.43, from the control

valve.

2.

Remove jam nut (1, Fig. 9.44) and hex nut (2)

from the tie rod (3) and carefully lift the outlet

section (4), the seal plates (5) and the working

sections (6 & 7) off of the tie rods (3). Remove

and discard all seals from the seal plate.

NOTE: When separating the sections, the load

sensing shuttle ball (11) may fall from the cavity

between the two working sections only. This ball

is a part of each seal plate kit and will be replaced

with a new part at assembly. DO NOT use this

ball between the inlet and raise/lower sections nor

between the outlet and extend/retract sections.

3.

Unscrew the tie rods (3) from the inlet section

(8).

MACHINE

FRONT

1

4

3

2

MOUNTED IN FRAME AT

VEHICLE CENTERLINE

BEHIND CAB

1.

Capscrew

2.

Nut

3.

Washer

4.

Control Valve

Fig. 9.42 Control Valve Mounting