SkyTrak 6036 Service Manual User Manual

Page 103

Section 8A

Perkins Engine

Model 6036/6036T S/N 9B0500 thru 14833

8A-11

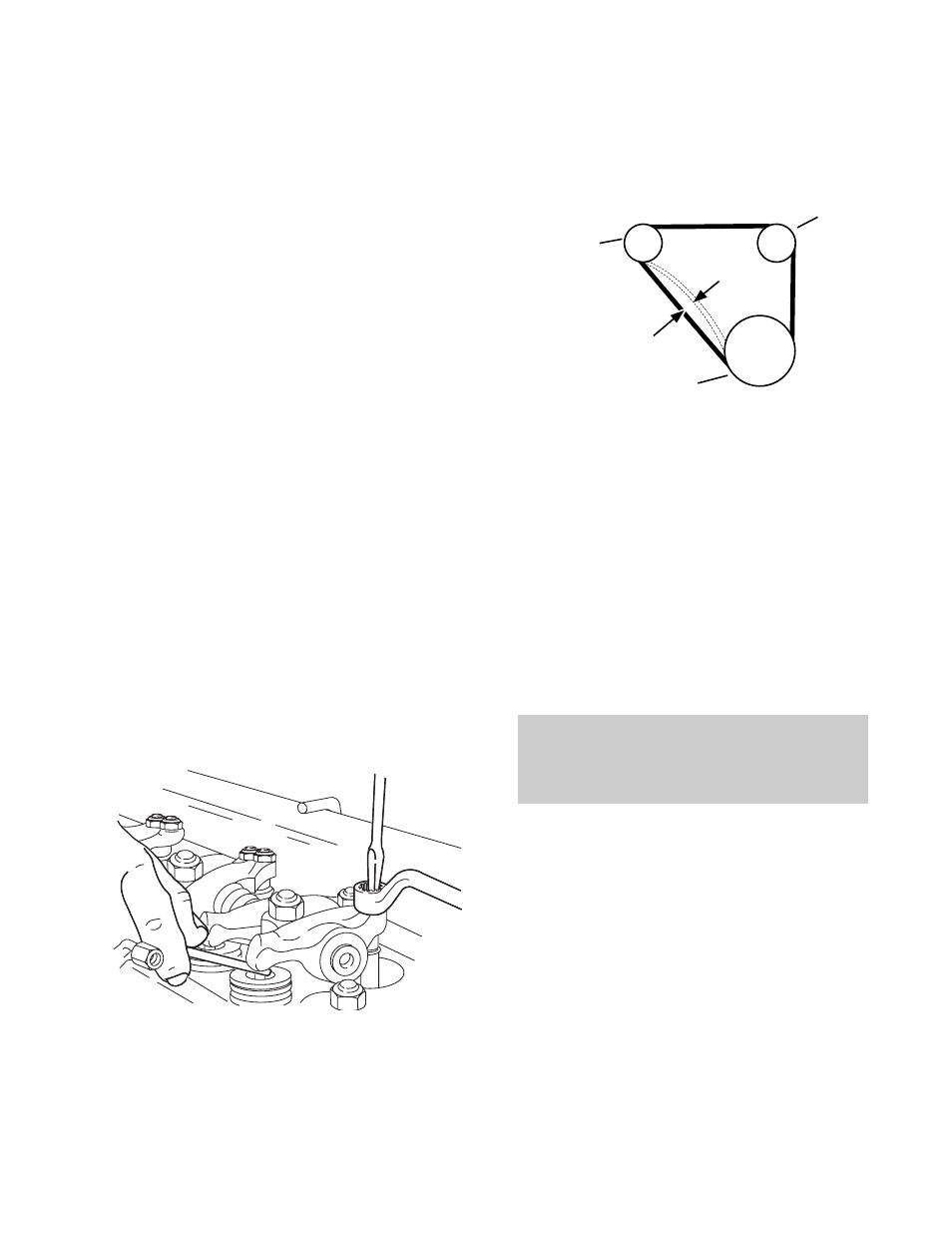

FAN PULLEY

ALTERNATOR

PULLEY

1/4" TO 3/8"

(6 TO 9 MM) BELT

DEFLECTION

CRANKSHAFT PULLEY

OA0362

Fig. 8A.21 Fan Belt Tension

8A.8.5 Inspect Fan Hub

Inspect the hub as follows:

1.

Remove fan belt.

2.

Check the fan hub bearing; the hub should

spin freely without any wobble or excessive

end play. Maximum end play is 0.006”

(0,15 mm).

3.

Install the fan belt.

8A.8.3 Check Valve Stem

to Rocker Arm Gap

Check and set valves with the engine cold—below

140 °F (60 °C). The correct gap between the top

of the valve stem and the rocker lever is 0.012"

(0,30 mm) with the engine cold.

NOTE: No. 1 cylinder is at the front of the engine.

To set these gaps:

1.

Turn the crankshaft in the normal direction of

rotation until the inlet valve of No. 4 cylinder

has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

clearances of the No. 1 cylinder valves and

adjust if necessary, Fig. 8A.20.

2.

Turn the crankshaft in the normal direction of

rotation until the inlet valve of No. 2 cylinder

has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

clearances of the No. 3 cylinder valves and

adjust if necessary.

3.

Turn the crankshaft in the normal direction of

rotation until the inlet valve of No. 1 cylinder

has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

clearances of the No. 4 cylinder valves and

adjust if necessary.

4.

Turn the crankshaft in the normal direction of

rotation until the inlet valve of No. 3 cylinder

has just opened and the exhaust valve of the

same cylinder has not fully closed. Check the

clearances of the No. 2 cylinder valves and

adjust if necessary.

MA1451

Fig. 8A.20 Checking Gap Between Valve Stem Tip

and Rocker Arm Lever

8A.9 ENGINE MAINTENANCE

Every 2,500 Hours

or 2 Years

All checks or inspections listed under daily or

previous maintenance intervals must also be

performed at this time in addition to those listed

under this maintenance interval.

1.

Inspect and service proprietary equipment

such as starter motor, alternator, turbocharger

(if applicable) etc.

2.

Service fuel injectors, paragraph 8A.13.8.

3.

Check and adjust valve stem tip to rocker arm

gap clearances, paragraph 8A.8.3.

4.

Visually inspect vibration dampers on motor

mounts.

8A.8.4 Check Fan Belt Tension

1.

Maximum fan belt deflection at the longest

span of the belt should be 1/4 to 3/8” (6 to 9

mm) with an applied force of 13 to 15 lbs.

(6 to 7 kg) Fig. 8A.21.