Warning – SkyTrak 6036 Service Manual User Manual

Page 284

Section 10.

Electrical System

10-22

Model 6036/6036T S/N 9B0500 thru 14833

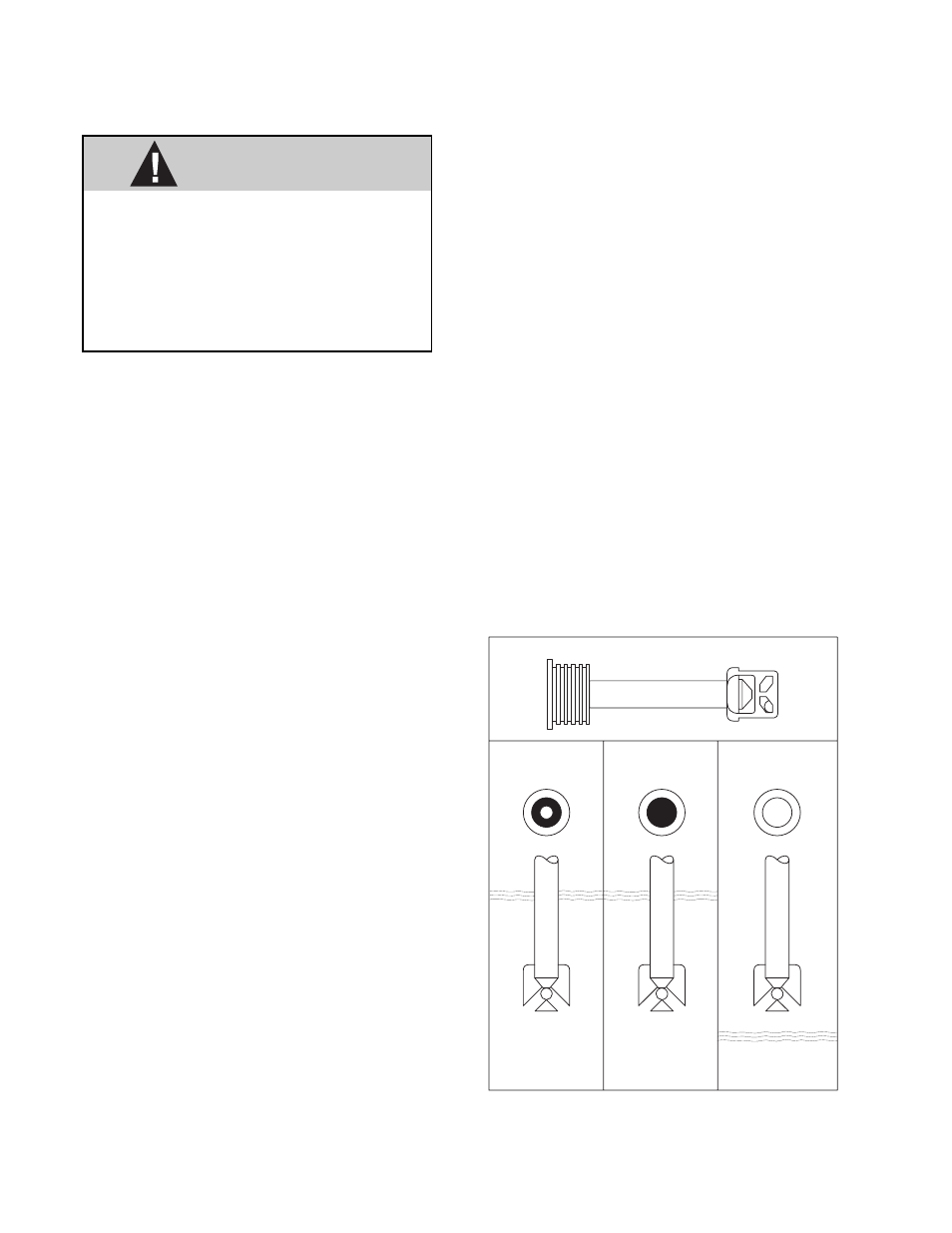

Fig. 10.15 Typical Hydrometer Operation

GREEN DOT

DARK

CLEAR

65% OR ABOVE

STATE OF

CHARGE

BELOW 65 %

STATE OF

CHARGE

LOW LEVEL

ELECTROLYTE

MA1201

10.6.2

Batteries

All lead-acid batteries generate hydrogen gas

which is highly flammable. If ignited by a spark

or flame, the gas may explode violently,

causing spraying of acid, fragmentation of the

battery, and possible severe personal injuries.

Wear safety glasses when working near

batteries. In case of contact with acid, flush

immediately with water.

a.

Description

The batteries supply power to the starter and

ignition systems to crank the engine. They supply

the extra power required when the electrical load

requirements of the forklift exceed the supply from

the charging system in case of a alternator or

charging failure, and acts as a voltage stabilizer in

the electrical system, smoothing out or reducing

temporarily high voltage.

With the correct cables properly attached, and with

the batteries properly mounted, the batteries never

need periodic maintenance.

When starting the forklift, crank for a maximum of

15 seconds, then rest for two minutes to avoid

burning up the starter. Do not idle excessively.

Keep the batteries from freezing by maintaining a

full charge. A completely discharged battery will

freeze at 18 °F (8 °C).

Water never has to be added to the batteries.

There are no filler caps. Each battery is sealed,

except for small vent holes in the cover. The

vents allow what small amount of gasses that are

produced in the battery to escape. The special

chemical composition inside the battery reduces

gassing to a very small amount at normal charging

voltages. Besides reducing gassing, the special

chemistry greatly reduces the possibility of over-

charge damage.

The vents require keeping the battery in an upright

position to prevent electrolyte leakage. Tipping

the battery beyond a 45° angle in any direction

can allow a small amount of electrolyte to leak out

the vent hole.

DO NOT exceed this 45° angle when carrying or

installing a battery.

Evidence of electrolyte leakage does not neces-

sarily mean a battery is defective.

Warning !

The battery has top post terminals. Securely

tighten clean cable clamps to the posts. Grease

or special spray sealers may be applied over the

connections.

b. Visual Inspection of a Battery

Inspect for damage such as a cracked or broken

case or cover that could permit loss of electrolyte.

If obvious physical damage is noted, replace

battery. Handle the battery with care. Determine

cause of damage and correct as needed.

c.

Built-In Hydrometer

A special temperature-compensated hydrometer

is built into the cover of each battery to show at a

glance the battery’s state-of-charge. The hy-

drometer has a green ball within a cage which is

attached to a clear plastic rod; refer to Fig. 10.15.

It is important when observing the hydrometer that

the battery have a clean top to see the correct

indication. A flashlight may be required in some

poorly lit areas.

IMPORTANT: Always look straight down when

viewing the hydrometer.