9 optional lighting system, 1 directional and emergency flasher switch – SkyTrak 6036 Service Manual User Manual

Page 305

Section 10.

Electrical System

10-43

Model 6036/6036T S/N 9B0500 thru 14833

GREEN

RED

BLACK

GRAY

GRAY/BLACK

BLUE

YELLOW

69431

5

2

5

3

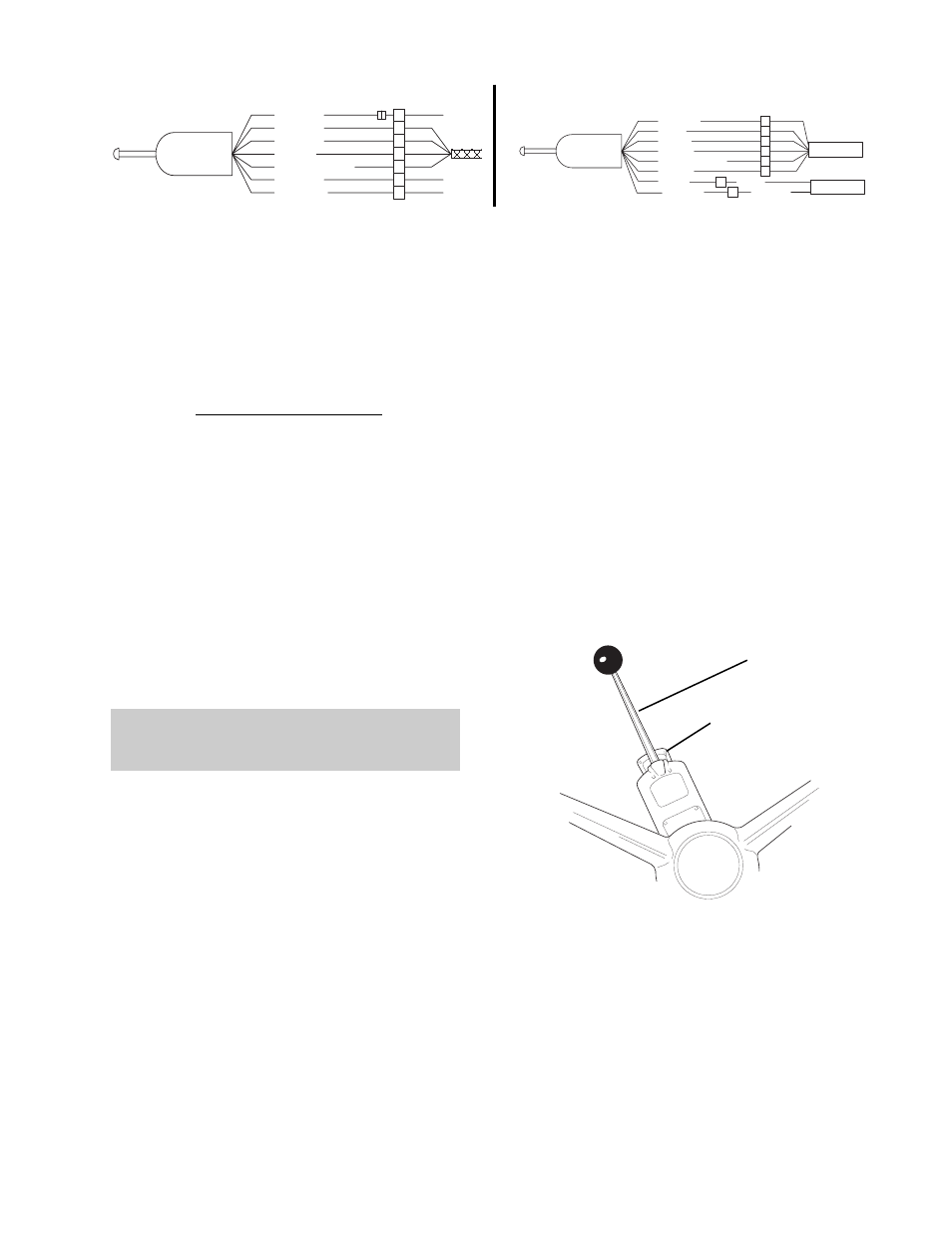

Fig. 10.32 Directional Signal Switch Lever and

Emergency Flasher Control Tab

Push the lever of the directional signal switch to

the left and down to signal a left turn; to the right

and up for a right turn. A green pilot light will flash

to indicate proper functioning. If pilot light doesn’t

flash, check for defective lamp or pilot bulb before

checking flasher.

The signals are not self-cancelling; the lever must

be moved to the center OFF position after the

indicated turn is negotiated.

Loose or corroded connections may cause a

discharged battery, difficult starting, dim lights, and

possible damage to the alternator and charging

circuit.

10.9.1

Directional and Emergency

Flasher Switch

The directional signal lever and the hazard (emer-

gency flasher) slide controls, Fig. 10.32, are

located directly below the steering wheel.

The ignition switch must be in the RUN position for

directional signal lights to be operated with the

directional signal switch lever.

With the directional signal switch in the neutral

position, stepping on the brake pedal will illumi-

nate the rear stop lights on both sides. If direc-

tional signals are operating on either side, step-

ping on the brake pedal will turn on the stop light

only on the side which is not flashing.

Fig. 10.31 Schematic of Directional Signal and Emergency Flasher Switch

DIRECTIONAL SIGNAL LEVER

EMERGENCY

FLASHER TAB

MA1341

OA0622

EARLY VERSION

LATER VERSION

MA6220

5.

Install nut and wire on the right (IGN) terminal

post.

IMPORTANT: Do not touch this wire to the left

(SEND) terminal post on the gauge or the sender

capsule will be damaged.

6.

Refer to paragraph 10.8.2 for the installation of

the gauge cluster.

Installation of the Sender

1.

Install a new gasket in the tank opening.

2.

Carefully tilt and lower the sender assembly

into the fuel tank.

3.

Loosely install the screw which secures the

ground wire to the sender and fuel tank.

4.

Install the other four screws and alternately

torque the five screws which secure the

sender to the fuel tank from 10 to 14 lb-inch

(1,13 to 1,58 Nm). Use No. 10-24 screws.

5.

Install the wire and nut on the center terminal

of the sender.

6.

Connect negative (–) cable to the batteries.

10.9 OPTIONAL

LIGHTING SYSTEM

The optional lighting, Fig. 10.30/10.30A provides:

• headlights, directional signal and hazard

warning lights at the front of the forklift;

• directional signal, hazard warning, stop and

tail lights and rear work lights at the rear of

the forklift;

• boom work light (later version only) and,

• an illuminated fuel level gauge.

The stop lights glow when the brake pedal is

pressed. The stoplights are combined with the

directional signal lights, emergency flasher lights

and tail lights.

Occasionally check to be sure:

• all wiring connections are tight and clean;

• that each lighting unit is tightly mounted to

provide a good ground, and

• that the headlights are properly adjusted.

GREEN

RED

BLACK

GRAY

GRAY/BLACK

BLUE

YELLOW

69431

WHITE

2

BLUE

YELLOW

FLASHER

HARNESS