Warning – SkyTrak 6036 Service Manual User Manual

Page 129

Section 8B

Cummins Engine

Model 6036/6036T S/N 9B0500 thru 14833

8B-9

• It is necessary to put the engine in the “Run”

position. Because the engine may start, be

sure to follow all the safety precautions. Use

the normal engine starting procedure.

• When using the starting motor to vent the

system, do not engage it for more than 30

seconds at a time; wait two minutes between

engagements.

30

0

15

45

RUN

STOP

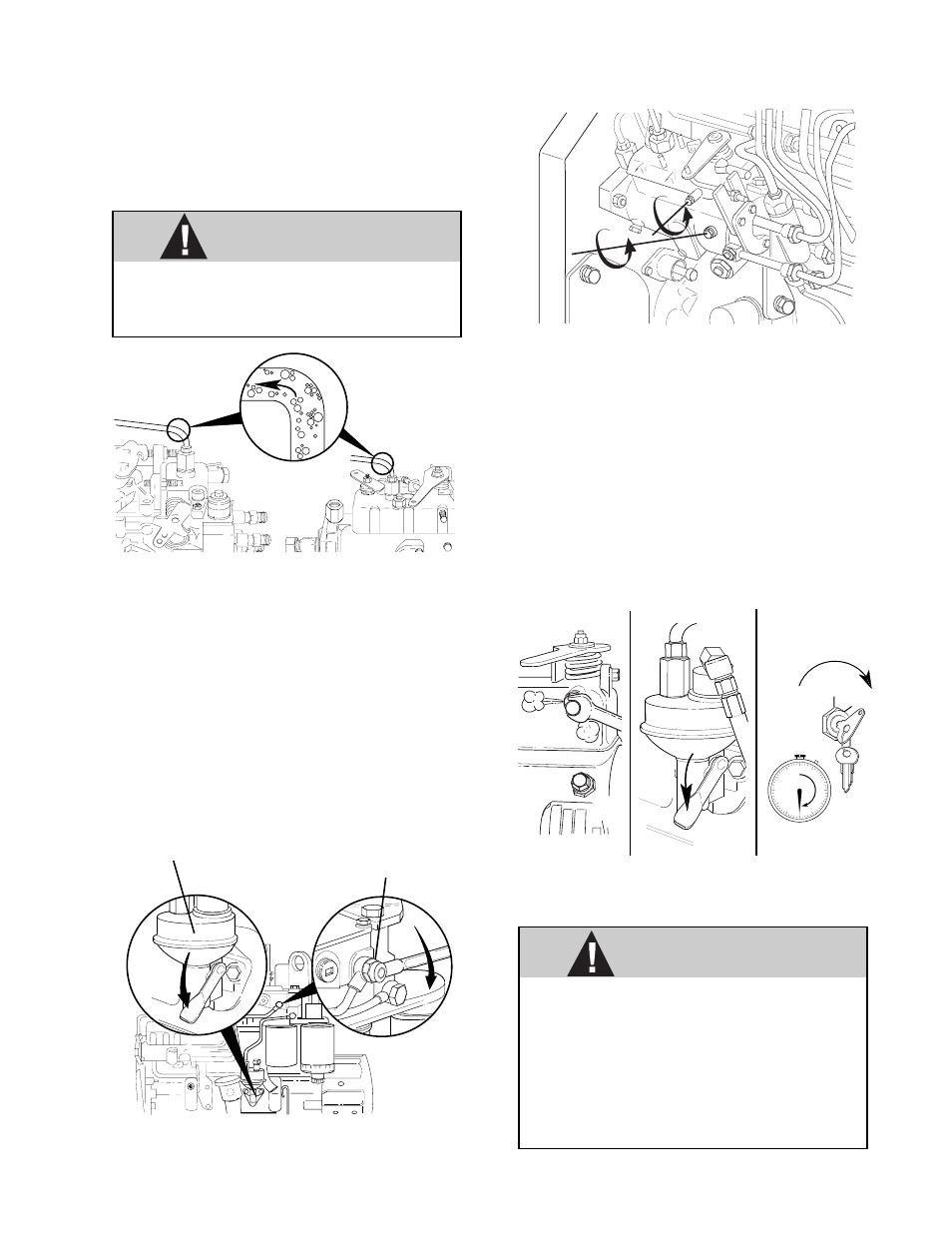

Controlled venting is provided at the injection

pump through the fuel drain manifold, Fig. 8B.16.

Small amounts of air introduced by changing the

filter elements or injection pump supply line are

vented automatically, if the fuel filter is changed in

accordance with the instructions.

Warning

Do not bleed air from a hot engine as this

could cause fuel to spill onto a hot exhaust

manifold creating a danger of fire.

Fig. 8B.17 Operating the Plunger on the Lift Pump

MA1840

FUEL LIFT PUMP

LOW PRESSURE LINE

VENT SCREW

Warning

BOSCH

CAV

MA1800

1.

To vent the low pressure lines and fuel

filter(s):

• Open the vent screw, Fig. 8B.17.

• Operate plunger on lift pump until the fuel

flowing from the fitting is free of air, Fig.

8B.17.

• Tighten the vent screw and torque it to

6 lb-ft (8 Nm), Fig. 8B.17.

Fig. 8B.16 Fuel Drain Manifold

Fig. 8B.19 Pumping from Fuel Lift Pump

MA1830

MA1690

MA1670

2.

Bleed the Lucas CAV injection pump at the

locations shown in Fig. 8B.18. Bosch pumps

do not need bleeding at the pump.

3.

Air/fuel can be pumped from this location, Fig.

8B.19, with the hand lever on the lift pump if

the fuel solenoid valve is energized. This

procedure will work for the Lucas CAV injec-

tion pump only.

Fig. 8B.18 Venting Air from Lucas CAV Injection

Pump

MA2050