8b.4.5 check air cleaner restriction indicator, 8b.4.6 check air cleaner vacuator valve, 8b.4.3 check engine oil level – SkyTrak 6036 Service Manual User Manual

Page 124: 8b.4.4 fill fuel tank

Section 8B

Cummins Engine

8B-4

Model 6036/6036T S/N 9B0500 thru 14833

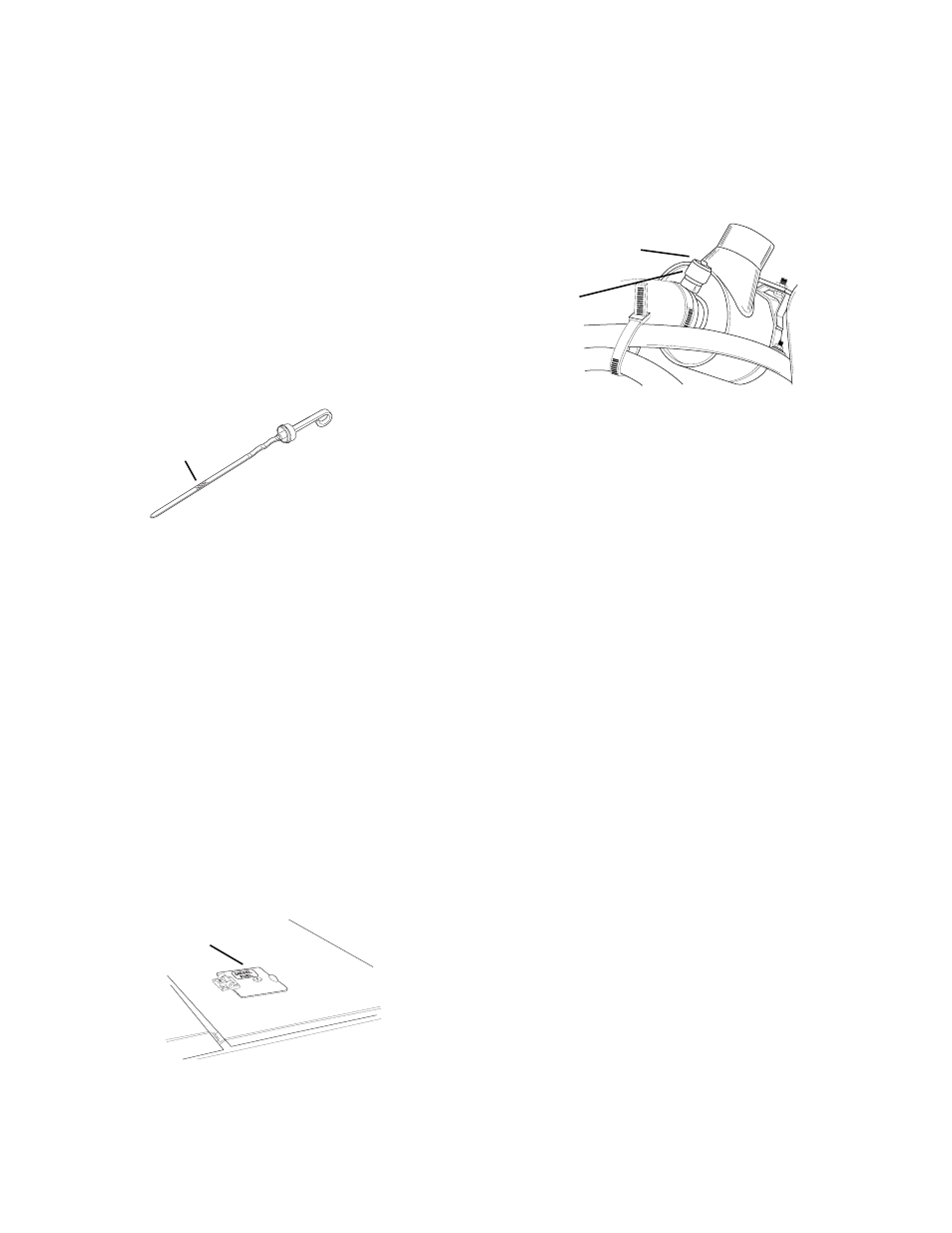

Fig. 8B.4 Air Cleaner Restriction Indicator

8B.4.5 Check Air Cleaner

Restriction Indicator

1.

Check air cleaner restriction indicator, Fig.

8B.4. If red band has appeared, clean or

replace the primary element as described in

paragraph 8B.4.7.

2.

Momentarily press reset button on top of

indicator after you service the primary el-

ement.

IMPORTANT: Never operate the engine without

air cleaner. Intake air must be filtered to prevent

dirt and debris from entering the engine and

causing premature wear.

NOTE: Maximum intake air restriction for a

turbocharged engine is 25" (635 mm) of water and

for a naturally aspirated engine is 20" (508 mm) of

water. You must operate a turbocharged engine

at rated rpm and full load when checking maxi-

mum intake air restriction. Clean or replace air

cleaner element before restriction reaches the

maximum allowable limit.

3.

Continue with next step.

8B.4.6 Check Air Cleaner

Vacuator Valve

1.

With the carriage lowered to the ground, the

engine shut-off and the park lock engaged,

unlock and open the right rear engine access

door.

2.

Remove dust and dirt from the vacuator valve,

Fig. 8B.5. The lips of the automatic dust

ejector must close but not adhere or stick

together.

3.

Continue with next step.

TEXT

HERE

OA0202

8B.4.3 Check Engine Oil Level

1. Wait at least 5 minutes after shutting off the

engine to check the oil. This allows time for

the oil to drain to the oil pan.

2.

Remove and check the engine oil level

dipstick, Fig. 8B.2.

3.

Oil should be within the crosshatched area.

4.

Replace dipstick.

5.

If required, add 10W30 or 15W40 motor oil

that is equal to API, CD or CE (severe duty

diesel engine) specifications. From the low

mark to the high mark, oil capacity is 1 quart

(0,95 liters). Refer to paragraph 8B.8 for oil

Specifications.

6.

Continue with next step.

OA1130

8B.4.4 Fill Fuel Tank

1.

Open fuel fill access door with key, Fig. 8B.3.

Fig. 8B.3 Fuel Fill Access Door

2.

When the coolant is hot, the bottle should be

3/4 full to full. When the coolant is cool, the

bottle should be 1/4 to 1/2 full.

3.

Remove cap on overflow bottle and add

coolant as required. Use a 50/50 mixture of

ethylene glycol and water. Protect the engine

to –34 °F (–37 °C) year round.

4.

Several weeks before you anticipate freezing

temperatures, check antifreeze concentration

using a hydrometer as described in paragraph

8B.9.1.

5.

Continue with next step.

NOTE: Use of a sealing additive to stop leaks in

the coolant system can plug coolant passages and

cause inadequate coolant flow.

OG0290

Fig. 8B.2 Engine Oil Level Dipstick

A

D

D

1 Q

T

FU

LL

CROSSHATCHED

AREA

RESTRICTION

INDICATOR

INDICATOR

WINDOW

FUEL FILL

ACCESS DOOR

2.

Remove fill cap and fill tank with Diesel Fuel

which meets or exceeds specifications in

paragraph 8B.11.1. Tank capacity is 24

gallons (90,8 liters).

3.

Install fill cap and lock fuel fill access door.

4.

Continue with next step.