4 park lock switch – SkyTrak 6036 Service Manual User Manual

Page 292

Section 10.

Electrical System

10-30

Model 6036/6036T S/N 9B0500 thru 14833

d. Inspection and Replacement

1.

Inspect the switch terminals for continuity and

shorting in the ENGAGED and DISENGAGED

positions.

2.

Replace switch if it fails the tests in step 1.

e.

Installation

1.

Connect electric wires as tagged during switch

removal.

2.

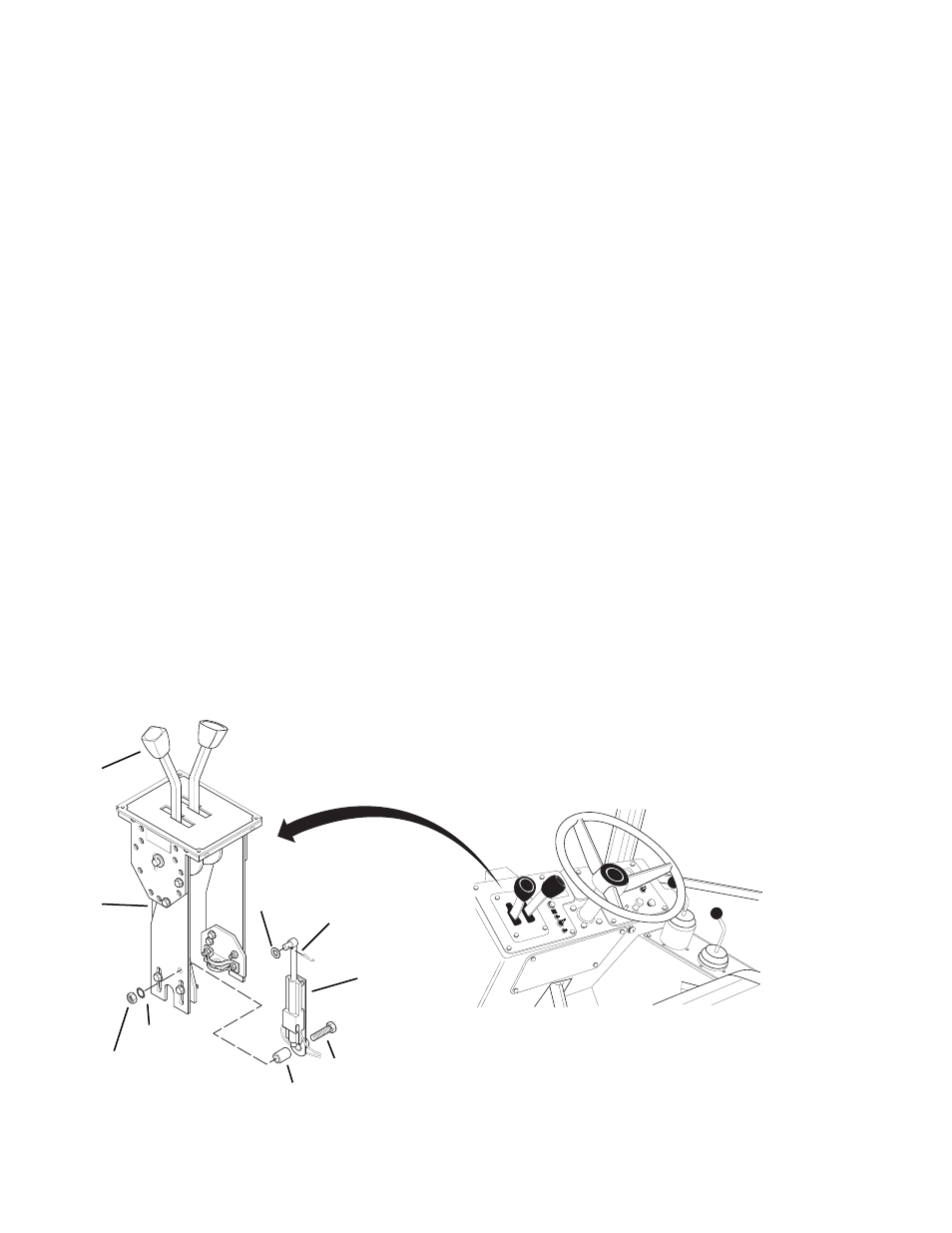

Position park lock switch, Fig. 10.21, under

panel.

3.

Position switch guard over switch stem.

4.

Install hex nut and hex nut cap seal.

5.

Connect negative (–) cable (2, Fig 10.16) to

batteries.

6.

Prepare to test park lock engagement and

disengagement by clearing the area around

the forklift of persons and any obstructions to

forklift travel.

• To test for engagement, engage the park

lock switch, place the drive in forward or

reverse and second or medium gear and

apply full throttle. The forklift should

remain motionless in both forward and

reverse positions.

• To test for disengagement, firmly depress

service brake pedal, disengage park lock

switch, place drive in forward or reverse

and first or low gear, and slowly press the

throttle pedal while releasing the brake

pedal. The park lock should release and

the forklift should be free to travel.

10.7.4

Park Lock Switch

The park lock switch, Fig. 10.21, has two posi-

tions, engaged and disengaged. To engage, lift

cover and flip lever up. To disengage, lower

switch cover.

a.

Removal

1.

Disconnect negative (–) cable (2, Fig. 10.16)

from batteries.

2.

Prepare to remove park lock switch, Fig.

10.21, by removing the lower panel which is

located below the switch.

3.

Tag and disconnect electric wires from the

switch.

4.

Remove hex nut cap seal and the hex nut

which secures switch to left front console

panel.

5.

Remove switch guard.

b. Disassembly

Do not disassemble the park lock switch.

c.

Cleaning and Drying

1.

Clean and condition the hex nut cap seal

using an appropriate vinyl cleaner.

2.

Without submerging the switch, clean the

switch with an approved solvent and dry with

a clean lint-free cloth.

7.

Spacer

8.

Plate

9.

Transmission Shifter

Fig. 10.22 Reverse Switch

N

R

F

DANGE

R

1.

Cotter Pin

2.

Washer

3.

Hex Nut

1

2

4

5

3

6

7

8

9

4.

Lock Washer

5.

Washer

6.

Capscrew

REVERSE

SWITCH

MA1261