Danger, Installation guide, Introduction – Veris Industries FSRxxxx SERIES Install User Manual

Page 6: Hazard of electric shock, explosion, or arc flash

FSRxxxx SERIES

Z205739-0D

PAGE 6

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

05131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

Because the transducers are non-contacting and have no moving parts, the flow

meter is not affected by system pressure, fouling, or wear. FST4 and FST5 transducers

are rated to a pipe surface temperature of -40 to +250 °F (-40 to +121 °C). FST1, FST2,

and FST3 small pipe transducers are rated from -40 to +185 °F (-40 to +85 °C).

Frequency

Transducers

Transmission

Modes

Pipe Size and

Type

2 MHz

All ½” thru 1½”

2” Tubing

Selected by

Firmware

Specific to

Transducer

1 MHz

2” ANSI and Copper

Selected by

Firmware

Specific to

Transducer

all 2” to 24”

W, V, and Z

2” to 24”

500 kHz

larger than 24”

W, V, and Z

24” and Greater

User Safety

The FSR Series employs modular construction and provides electrical safety for the

operator. The display face contains voltages no greater than 28 VDC. The display face

swings open to allow access to user connections.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Disconnect electrical power before opening the instrument enclosure.

• Wiring must conform to applicable codes.

Failure to follow these instructions will result in death or serious injury.

Data Integrity

Non-volatile flash memory retains all user-entered configuration values in memory

for several years at 77°F (25°C), even if power is lost or turned off. Password

protection is provided as part of the Security menu (SEC MENU) and prevents

inadvertent configuration changes or totalizer resets.

Product Identification

The serial number and complete model number of the monitor are located on the top

outside surface of the housing. If technical assistance is required, please provide the

Customer Service Department with this information.

INTRODUCTION

General

The Veris ultrasonic flow meter is designed to measure the fluid velocity of liquid

within a closed conduit. The transducers are a non-contacting clamp-on or clamp-

around type that does not foul and is easy to install.

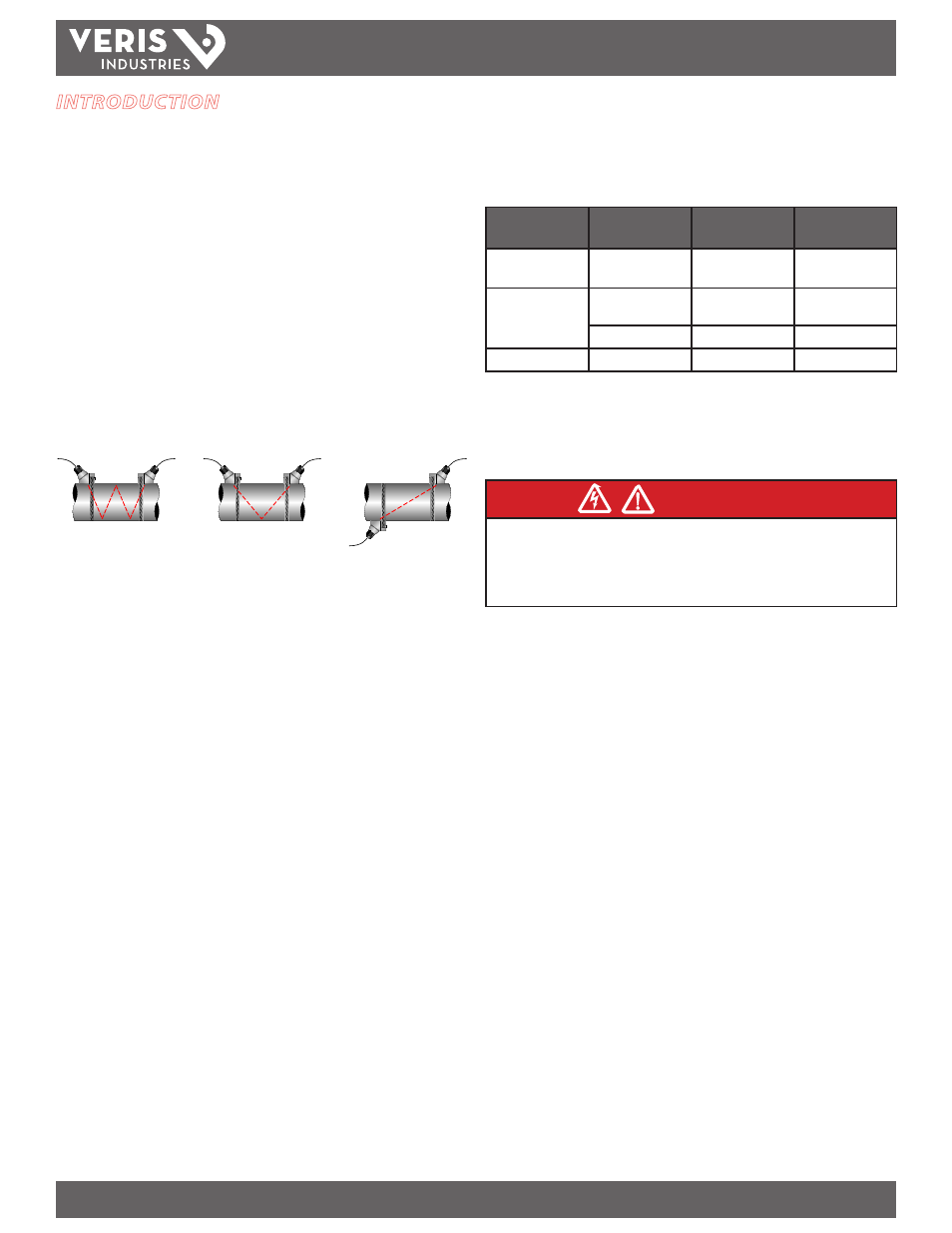

The Veris family of transit time flow meters utilize two transducers that function

as both ultrasonic transmitters and receivers. The transducers are clamped on

the outside of a closed pipe at a specific distance from each other. The transducers

can be mounted in V-Mount where the sound transverses the pipe two times,

W-Mount where the sound transverses the pipe four times, or in Z-Mount where the

transducers are mounted on opposite sides of the pipe and the sound crosses the pipe

once. The selection of mounting method is based on pipe and liquid characteristics

that both have an effect on how much signal is generated. The flow meter operates

by alternately transmitting and receiving a frequency modulated burst of sound

energy between the two transducers and measuring the time interval that it takes

for sound to travel between the two transducers. The difference in the time interval

measured is directly related to the velocity of the liquid in the pipe.

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

W-Mount

V-Mount

Z-Mount

Figure 1.1 - Ultrasound Transmission

Application Versatility

The FSRxxxx flow meter can be successfully applied on a wide range of metering

applications. The simple-to-program monitor allows the standard product to be used

on pipe sizes ranging from ½ inch to 100 inches (12 mm to 2540 mm) pipe*. A variety

of liquid applications can be accommodated:

ultrapure liquids

potable water

chemicals

sewage

reclaimed water

cooling water

river water

plant effluent

others