Installation guide, Part 4 - startup and configuration – Veris Industries FSRxxxx SERIES Install User Manual

Page 18

FSRxxxx SERIES

Z205739-0D

PAGE 18

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

05131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

PART 4 - STARTUP AND CONFIGURATION

Before Starting the Instrument

Note: Flow meter systems require a full pipe of liquid before a successful start-up can be

completed. Do not attempt to make adjustments or change configurations until a full pipe is

verified.

Note: If Dow 732 RTV was used to couple the transducers to the pipe, the adhesive must be

fully cured before readings are attempted. Dow 732 requires 24 hours to cure satisfactorily. If

Sonotemp® acoustic coupling grease was utilized as a couplant, curing is not required.

Instrument Startup

1. Verify that all wiring is properly connected and routed, as described in Part 1 of

this manual.

2. Verify that the transducers are properly mounted, as described in Part 2 of this

manual.

3. Apply power. The display briefly shows a software version number and then all of

the segments illuminate in succession.

Important!: In order to complete the installation of the flow meter, the

pipe must be full of liquid.

To verify proper installation and flow measurement operation:

1. Go to the SER MENU and confirm that signal strength (SIG STR) is between 5 and

98. If the signal strength is lower than 5, verify that proper transducer mounting

methods and liquid/pipe characteristics have been entered. To increase signal

strength, if a W-Mount transducer installation was selected, re-configure for a

V-Mount installation (standard from factory); if V-Mount was selected, re-

configure for Z-Mount.

Note: Mounting configuration changes apply only to FST4, FST5 transducer sets.

2. Verify that the actual measured liquid sound speed is within 2% of the value

entered as FLUID SS in the BSC MENU. The measured liquid sound speed (SSPD

FPS and SSPD MPS) is displayed in the SER MENU. The pipe must be full of liquid in

order to make this measurement.

Keypad Programming

Configure units with keypads using the keypad interface or by using the Windows®

compatible software utility. Units without a keypad can only be configured using the

software utility. See Part 5 of this manual for software details. Of the two methods

of configuration, the software utility provides more advanced features and offers

the ability to store and transfer meter configurations between meters. All entries

are saved in non-volatile flash memory and are retained indefinitely in the event of

power loss.

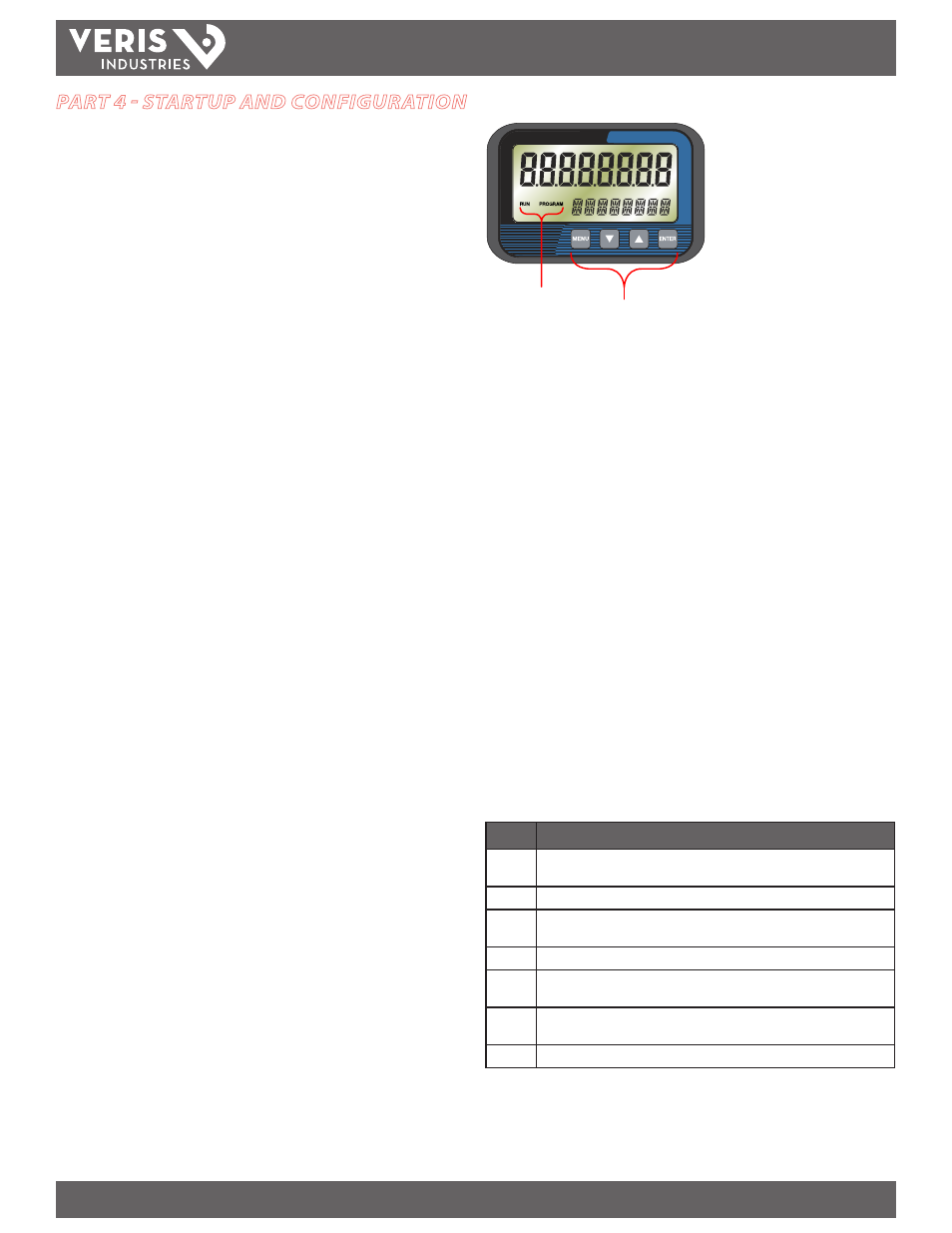

The four-key tactile feedback keypad interface allows the user to view and change

configuration parameters used by the operating system.

Keypad

Mode

Indicators

Figure 4.1 - Keypad Interface

1. Press the MENU key from RUN mode to enter PROGRAM mode. Press the MENU key

in PROGRAM mode to exit from configuration parameter selection and menus. If

changes to any configuration parameters are made, the user is prompted with a

SAVE? when returning to RUN mode. Choose YES to save the new parameters in

program memory.

2. The arrow ▼ keys are used to scroll through menus and configuration

parameters. The arrow keys are also used to adjust parameter numerical values.

3. The ENTER key functions are:

• Pressed from the RUN mode to view the current software version

operating in the instrument.

• Used to access the configuration parameters in the various menus.

• Used to initiate changes in configuration parameters.

• Used to accept configuration parameter changes.

Menu Structure

The flow meter firmware uses a hierarchical menu structure. A map of the user

interface is included in the Appendix of this manual. The map provides a visual path

to the configuration parameters that users can access. Employ this tool each time

configuration parameters are accessed or revised.

The seven menus used in the software are as follows:

Menu

Description

BSC

Basic. Contains all of the configuration parameters necessary to initially program

the meter to measure flow.

CH1

Channel 1. Configures the 4-20 mA output.

CH2

Channel 2. Configures the type and operating parameters for channel 2 output

options. Channel 2 parameters are specific to the model used.

SEN

Sensor. Used to select the sensor type (i.e. FST1, FST2, etc.).

SEC

Security. Used for resetting totalizers, returning filtering to factory settings, and

revising the security password.

SER

Service. Contains system settings used for advanced configuration and zeroing

the meter on the pipe.

DSP

Display. Used to configure meter display functions.