Installation guide – Veris Industries FSRxxxx SERIES Install User Manual

Page 10

FSRxxxx SERIES

Z205739-0D

PAGE 10

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

05131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

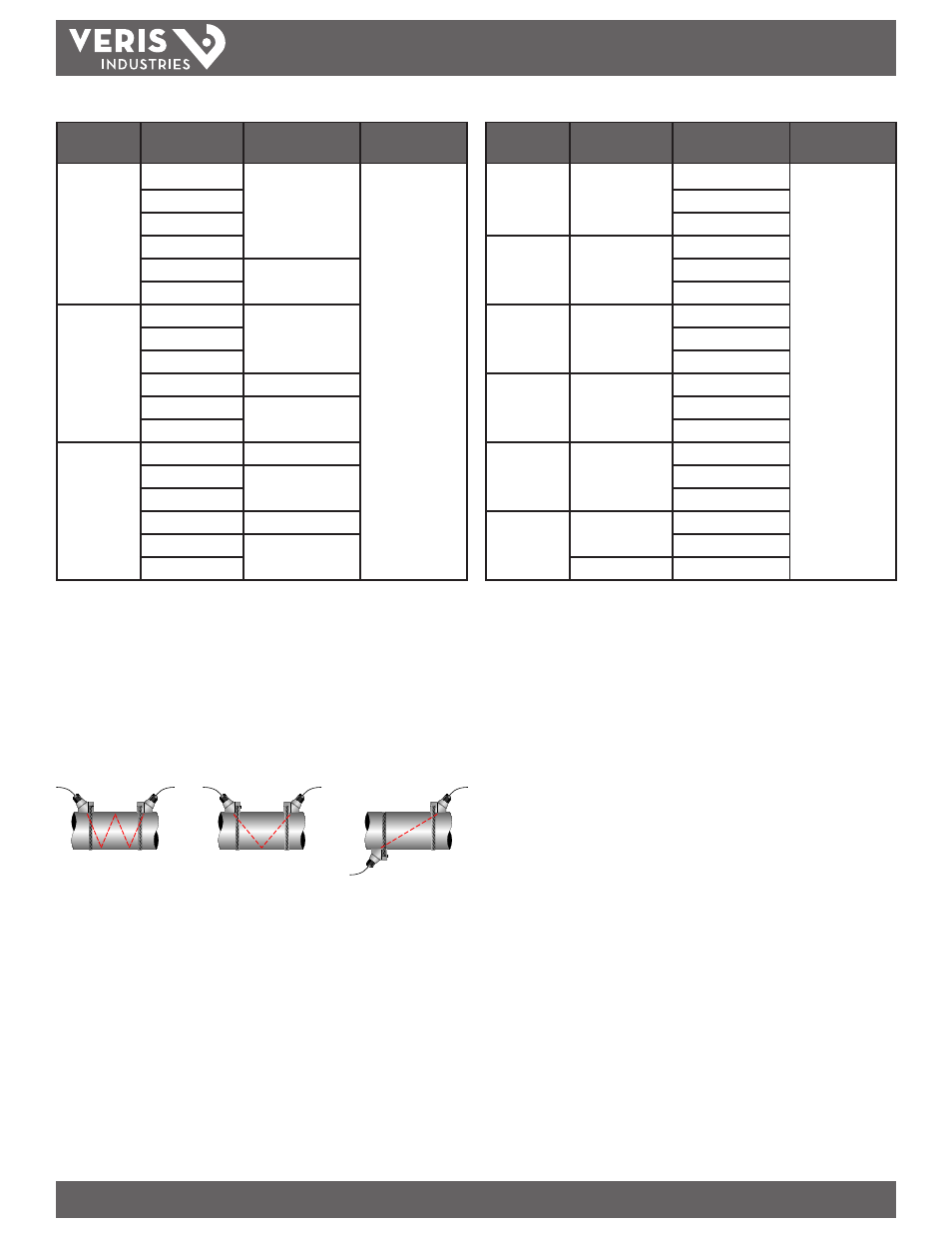

Mounting

Mode

Pipe Material

Pipe Size

Liquid

Composition

W-Mount

Plastic (all types)

2-4 in. (50-100 mm)

Low TSS; non-aerated

Carbon Steel

Stainless Steel

Copper

Ductile Iron

Not Recommended

Cast Iron

V-Mount

Plastic (all types)

4-12 in. (100-300 mm)

Carbon Steel

Stainless Steel

Copper

4-30 in. (100-750 mm)

Ductile Iron

2-12 in. (50-300 mm)

Cast Iron

Z-Mount

Plastic (all types)

> 30 in. (>750 mm)

Carbon Steel

>12 in. (>300 mm)

Stainless Steel

Copper

> 30 in. (>750 mm)

Ductile Iron

>12 in. (>300 mm)

Cast Iron

Table 2.2 - Transducer Mounting Modes — FST4, FST5

For further details, reference Figure 2.1. The appropriate mounting configuration is

based on pipe and liquid characteristics. Selection of the proper transducer mounting

method is not entirely predictable and many times is an iterative process. Table 2.2

contains recommended mounting configurations for common applications. These

recommended configurations may need to be modified for specific applications

if such things as aeration, suspended solids, out of round piping or poor piping

conditions are present. Use of meter diagnostics in determining the optimum

transducer mounting is covered later in this section.

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

W-Mount

V-Mount

Z-Mount

Figure 2.1- Transducer Mounting Modes — FST4, FST5

Size

Frequency

Setting

Transducer

Mounting Mode

1/2

2 MHz

FST1

V

FST2

FST3

3/4

2 MHz

FST1

FST2

FST3

1

2 MHz

FST1

FST2

FST3

1 1/4

2 MHz

FST1

FST2

FST3

1 1/2

2 MHz

FST1

FST2

FST3

2

1 MHz

FST1

FST2

2 MHz

FST3

Table 2.3 - Transducer Mounting Modes — FST1, FST2, FST3

Step 3 - Entering Pipe and Liquid Data

The system calculates proper transducer spacing by utilizing piping and liquid

information entered by the user. Enter this information via the keypad or via the

optional software utility.

The best accuracy is achieved when transducer spacing is exactly what the meter

calculates, so use the calculated spacing if signal strength is satisfactory. If the pipe is

not round, the wall thickness is not correct, or the actual liquid being measured has a

different sound speed than the liquid programmed into the transmitter, the spacing

can vary from the calculated value. If that is the case, place the transducers sat the

highest signal level observed by moving the transducers slowly around the mount

area.

Note: Transducer spacing is calculated on “ideal” pipe. Ideal pipe is almost never found so the

transducer spacing distances may need to be altered. An effective way to maximize signal strength

is to configure the display to show signal strength, fix one transducer on the pipe and then starting

at the calculated spacing, move the remaining transducer small distances forward and back to

find the maximum signal strength point.

Important! Enter all of the data on this list, save the data, and reset the

meter before mounting transducers.