Installation guide, Rc us, Product service – Veris Industries FSRxxxx SERIES Install User Manual

Page 17: Minc o, Figure 3.13 - connecting rtds, Minco, Figure 3.11 - surface mount rtd installation

FSRxxxx SERIES

Z205739-0D

PAGE 17

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

05131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

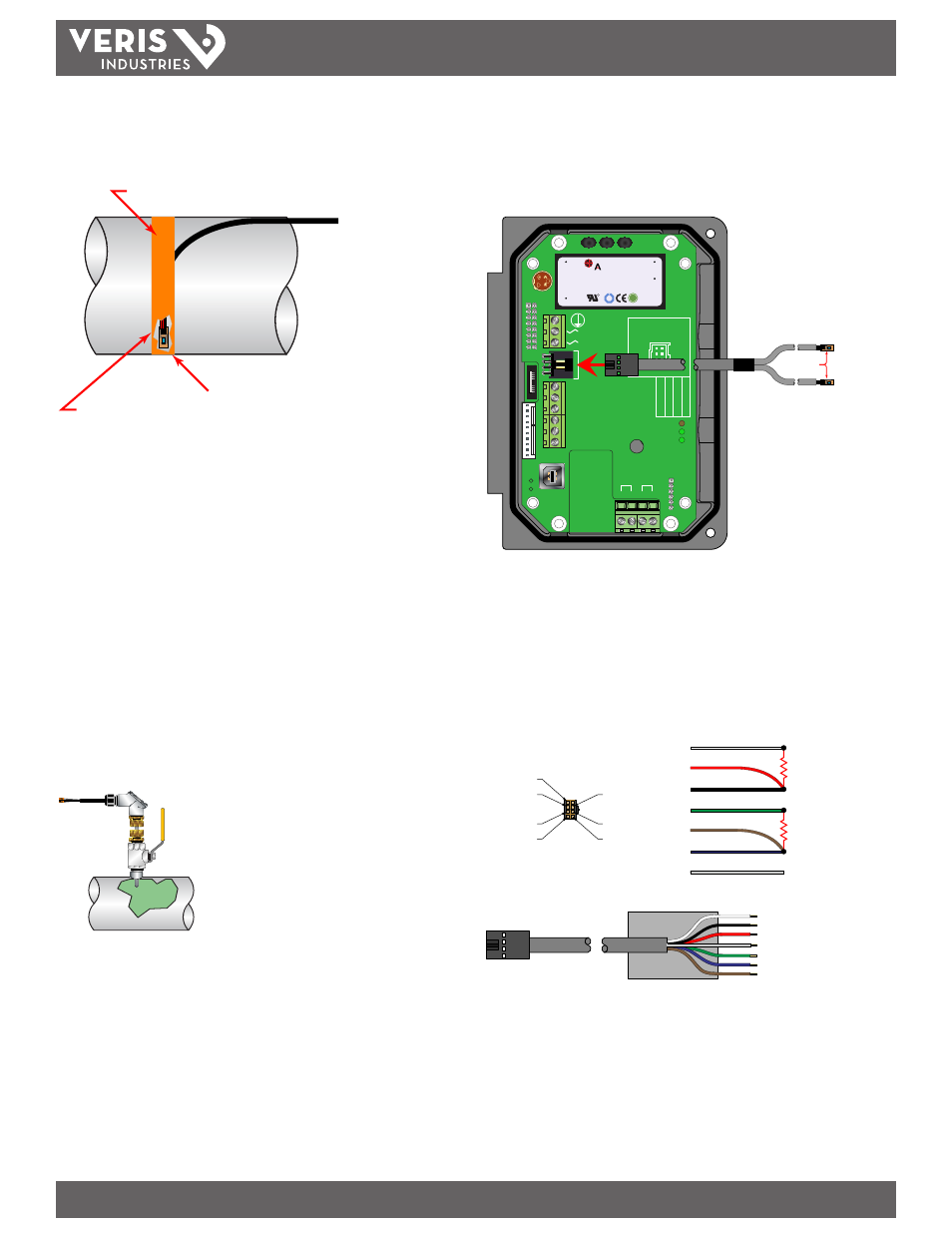

Wiring to Meter

After the RTDs have been mounted to the pipe, route the cable back to the meter

through the middle hole in the enclosure. Connect to the meter inserting the RTD

connector into the mating connector on the circuit board.

95 - 264 VAC

AC Neutral

Signal Gnd.

4-20 mA Out

Reset Total

Modbus Gnd

Modbus B

Modbus A

D

ownstr

eam

Upstr

eam

+

+

- -

RTD 1 RTD 2

TEMP

. SE

T

0 t

o 50°C

0 t

o 100°C

-40 t

o 200°C

Modbus

TFX Rx

TFX Tx

Exc.

Sig.

Gnd.

Shield

Exc.

Sig.

Gnd.

Shield

W

R

C US

1500mA250V

D

VE

372

R

C US

E167432

$

TUV

PRODUCT SERVICE

RoHS

AC IN : 100-240VAC,50/60Hz

DC OUT :

+15V / 0.3A

PWC-15E

0.15A

R2807

www.astrodyne.com

-Vo

+Vo

ACL

ACN

strodyne

RETURN LINE

RTD #2

MINC

O

SUPPLY LINE

RTD #1

MINC

O

RTD’s

Figure 3.13 - Connecting RTDs

Replacement RTDs

Complete RTD kits, including the energy meters plug-in connector and calibration

values for the replacements, are available from the manufacturer.

It is also possible to use other manufacturer’s RTDs. The RTDs must be 1000 Ω

platinum RTDs suitable for a three-wire connection. A connection adapter is available

to facilitate connection to the meter. See Figure 3.14.

PIN #1

PIN #3

PIN #5

PIN #2

PIN #4

PIN #6

PIN #8

RTD2

RTD1

WHITE

RED

BLACK

GREEN

BROWN

BLUE

DRAIN

WHITE

BLACK

RED

GREEN

BLUE

BROWN

DRAIN

PIN#3

PIN#6

PIN#1

PIN#8

PIN#4

PIN#2

PIN#5

Figure 3.14 - RTD Adapter Connections

Note: It will be necessary to calibrate third party RTDs to the meter for proper operation. See the

Appendix of this manual for the calibration procedure.

Route the RTD cables back to the flow meter and secure the cable so that it will not be

pulled on or abraded inadvertently. Replace the insulation on the pipe, ensuring that

the RTDs are not exposed to air currents.

MINCO

Clean RTD Mounting

Area to Bare Metal Surface

Heat Sink

Compound

Heat Tape

Figure 3.11 - Surface Mount RTD Installation

Installation of Insertion RTDs

Insertion RTDs are typically installed through ¼ inch (6 mm) compression fittings

and isolation ball valves. Insert the RTD sufficiently into the flow stream such that a

minimum of ¼ inch (6 mm) of the probe tip extends into the pipe diameter. Only use

insertion (wetted) RTDs on pipes that are not insulated.

Mount RTDs within ±45 degrees of the side of a horizontal pipe. On vertical pipes the

orientation is not critical. Route the RTD cables back to the flow meter and secure the

cable so that it will not be pulled on or abraded inadvertently.

If the cables are not long enough to reach the meter, route the cables to an electrical

junction box and add additional cable from that point. Use three-wire shielded cable,

such as Belden® 9939 or equal, for this purpose.

Note: Adding cable adds to the resistance the meter reads and may have an effect on absolute

accuracy. If cable is added, ensure that the same length is added to both RTDs to minimize errors

due to changes in cable resistance.

Figure 3.12 - Insertion Style RTD Installation