Installation guide, Small pipe transducer installation – Veris Industries FSRxxxx SERIES Install User Manual

Page 12

FSRxxxx SERIES

Z205739-0D

PAGE 12

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

05131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

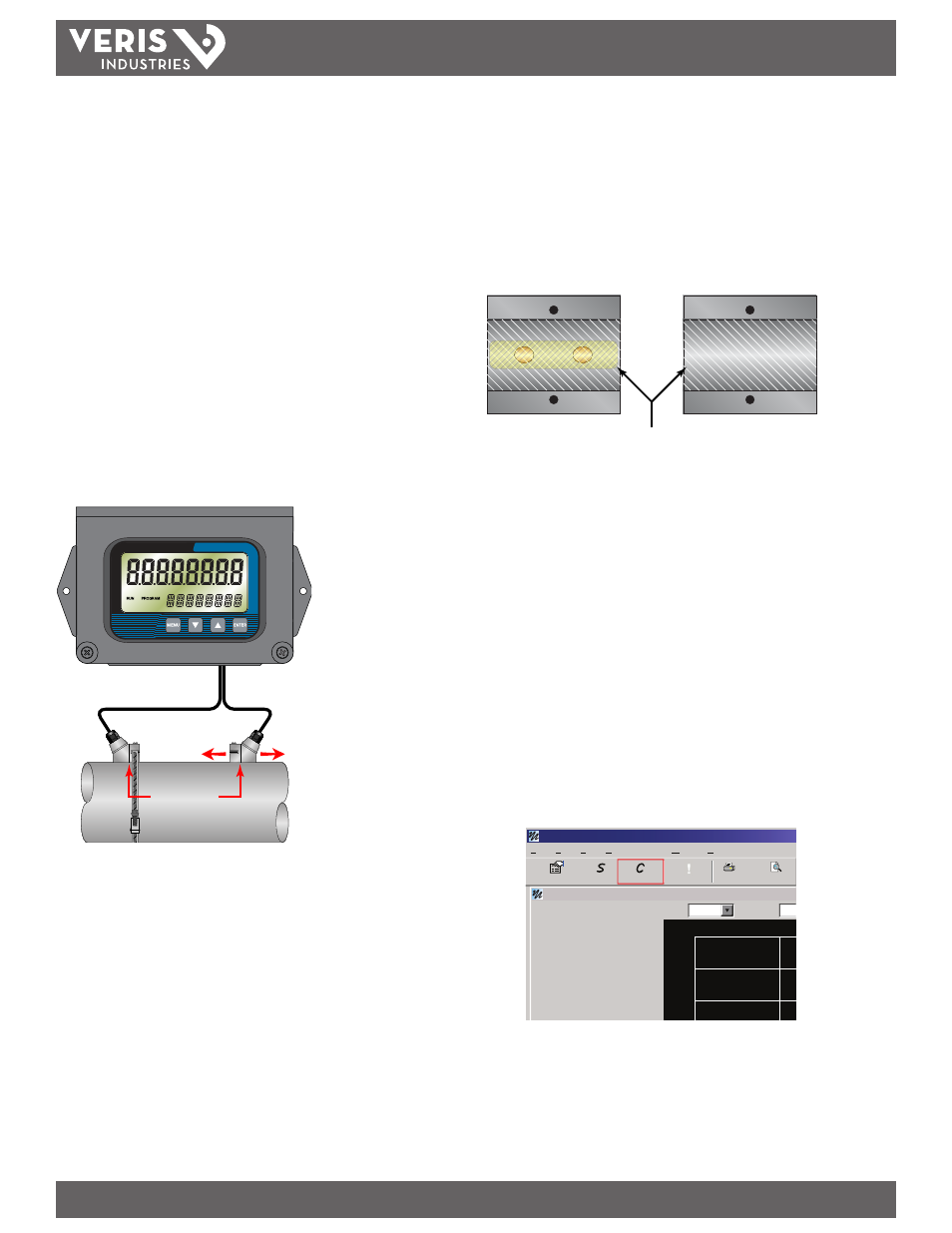

Transducer Positioning

1. Place the upstream transducer in position and secure with a mounting strap. Place

straps in the arched groove on the end of the transducer. A screw is provided to

help hold the transducer onto the strap. Tighten the transducer strap securely.

2. Place the downstream transducer on the pipe at the calculated transducer spacing.

See Figure 2.5. Apply firm hand pressure. If signal strength is greater than 5,

secure the transducer at this location. If the signal strength is not 5 or greater

then using firm hand pressure, slowly move the transducer both towards and

away from the upstream transducer while observing signal strength. Clamp

thetransducer where the highest signal strength is observed. Signal levels much

less than 5 may not yield acceptable data.

Note: Signal strength readings update only every few seconds, so it is advisable to move

the transducer 1/8”, wait, see if signal is increasing or decreasing and then repeat until

the highest level is achieved.

3. If after adjustment of the transducers the signal strength does not rise to above 5,

then select an alternate transducer mounting method. If the mounting method

was W-Mount, then re-configure the monitor for V-Mount, move the downstream

transducer to the new spacing distance and repeat Step 4.

Transducer

Spacing

Figure 2.5 - Transducer Positioning

Small Pipe Transducer Installation

The small pipe transducers are designed for specific pipe outside diameters. Do not

attempt to mount a transducer onto a pipe that is either too large or too small for the

transducer.

FST1, FST2, and FST3 installation consists of the following steps:

1. Apply a thin coating of acoustic coupling grease to both halves of the transducer

housing where the housing will contact the pipe. See Figure 2.6.

1/16” (1.5 mm)

Acoustic Couplant Grease

Figure 2.6 - Application of Acoustic Couplant — FST1, FST2, FST3 Transducers

2. On horizontal pipes, mount the transducer in an orientation such that the cable

exits at ±45 degrees from the side of the pipe. Do not mount with the cable

exiting on either the top or bottom of the pipe. On vertical pipes the orientation

does not matter. See Figure 2.2.

3. Tighten the wing nuts or “U” bolts so that the acoustic coupling grease begins to

flow out from the edges of the transducer or from the gap between the transducer

halves. Do not over tighten.

4. If signal strength is less than 5, remount the transducer at another location on the

piping system.

5. Configuration Procedure:

a. Establish communications with the transit tme meter. See Part 5 -

Software Utility.

b. From the tool bar, select calibration.

Device Addr 127

Flow:

Totalizer Net:

Pos:

Neg:

Sig. Strength:

Margin:

Delta T:

Last Update:

Help

Window

Communications

View

Edit

File

Print Previe

1350 Gal/Min

0 OB

15.6%

100%

-2.50 ns

09:53:39

0 OB

0 OB

Errors

rro

!

Configuration

Calibration

Strategy

1600

2000

1200

Scale:

60 Min

Time:

200

USP - Device Addr 127

c. On the pop-up screen, click Next twice to get to page 3 of 3. Click Edit in this

screen.