Installation guide, Flow tab, Filtering tab – Veris Industries FSRxxxx SERIES Install User Manual

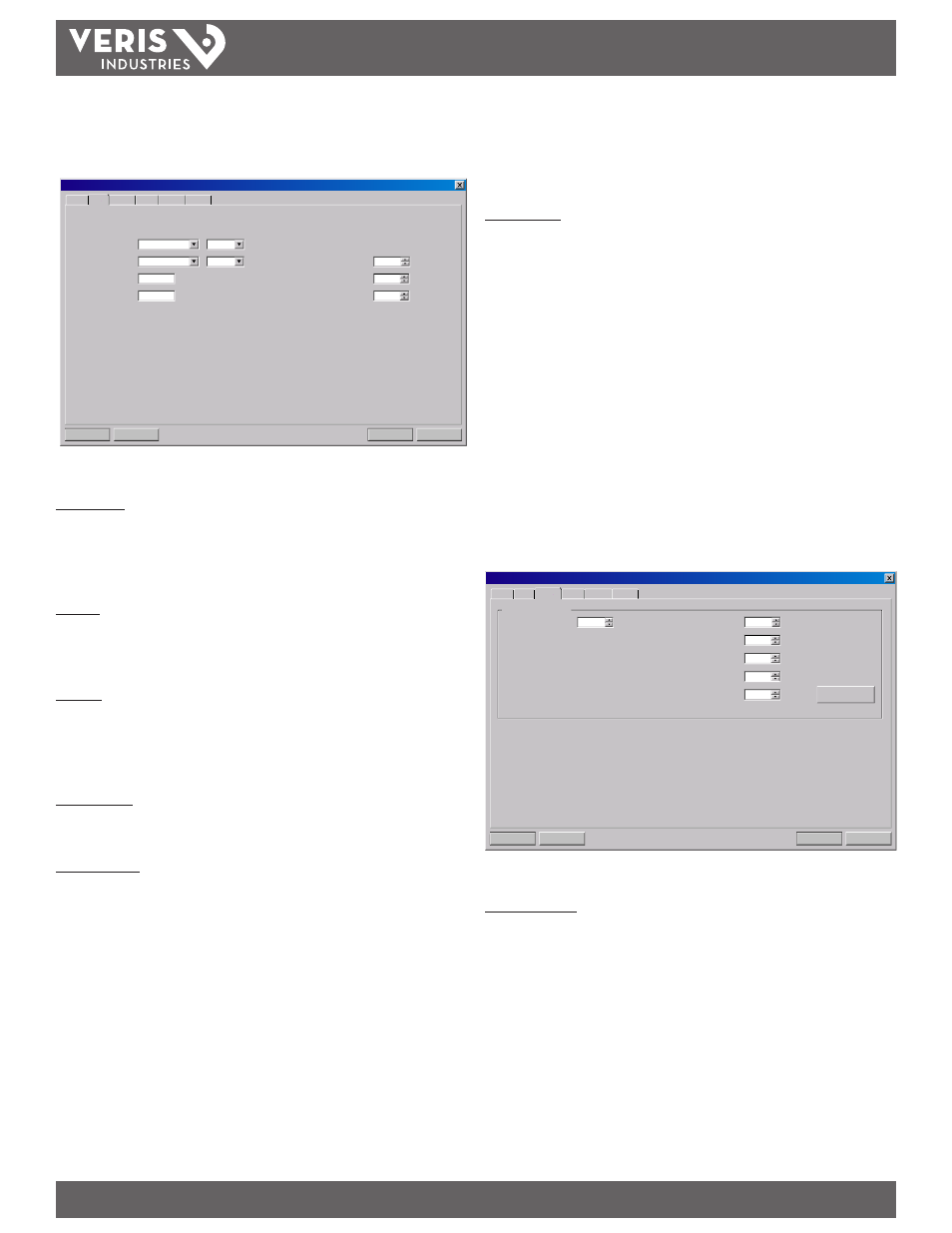

Page 30: Figure 5.3 - flow tab, Figure 5.4 - filtering tab

FSRxxxx SERIES

Z205739-0D

PAGE 30

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

05131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

Flow Tab

Select flow rate units and a flow rate interval from the drop-down lists.

Download

Cancel

File Open...

File Save...

System Configuration

Display

Basic Flow Filtering Output Security

Gallons

Min

Flow Rate Units:

/

Gallons

X10

Totalizer Units:

0.0

Min Flow:

Gal/M

Gal/M

400.0

Max Flow:

Low Flow Cutoff:

Low Signal Cutoff:

%

%

Substitute Flow:

2

2

0

Figure 5.3 - Flow Tab

Totalizer Units are selected from drop-down lists. Select an appropriate totalizer unit

and totalizer exponent. The totalizer exponents are in scientific notation and permit

the eight digit totalizer to accumulate very large values before the totalizer “rolls

over” and starts again at zero. Table 4.4 illustrates the scientific notation values and

their respective decimal equivalents.

Min Flow is the minimum volumetric flow rate to establish filtering parameters.

Volumetric entries are in the flow rate units. For unidirectional measurements,

set Min Flow to zero. For bidirectional measurements, set Min Flow to the highest

negative (reverse) flow rate expected in the piping system.

Max Flow is the maximum volumetric flow rate to establish filtering parameters.

Volumetric entries are in the Flow Rate Units. For unidirectional measurements,

set Max Flow to the highest (positive) flow rate expected in the piping system.

For bidirectional measurements, set Max Flow to the highest (positive) flow rate

expected in the piping system.

Low Flow Cutoff is provided to allow very low flow rates (present when pumps are off

and valves are closed) to be displayed as zero flow. Typical values that are between

1.0% and 5.0% of the flow range between Min Flow and Max Flow.

Low Signal Cutoff is used to drive the flow meter and its outputs to the value

specified in the Substitute Flow field when conditions occur that cause low signal

strength. A signal strength below 5 is inadequate for measuring flow reliably, so the

minimum setting for Low Signal Cutoff is 5. A good practice is to set the Low Signal

Cutoff at approximately 60-70% of actual measured maximum signal strength.

Note: The factory default “Low Signal Cutoff” is 5.

If the measured signal strength is lower than the Low Signal Cutoff setting, a “Signal

Strength too Low” highlighted in red appears in the text area to the left in the Data

Display screen until the measured signal strength becomes greater than the cutoff

value.

Signal strength indication below 2 is considered to be no signal at all. Verify that the

pipe is full of liquid, the pipe size and liquid parameters are entered correctly, and the

transducers are mounted accurately. Highly aerated liquids cause low signal strength

conditions.

Substitute Flow is a value that the analog outputs and the flow rate display show to

indicate that an error condition in the flow meter has occured.

Substitute Flow is set as a percentage between Min Flow and Max Flow. In a

unidirectional system, this value is typically set to zero to indicate zero flow while

in an error condition. To calculate where to set the Substitute Flow value in a

bidirectional system, perform the following operation:

Substitute Flow = 100 - (100

×

max. flow) / (max. flow - min. flow)

Entry of data in the Basic and Flow tabs is all that is required to provide flow

measurement functions to the flow meter. If the user is not going to utilize input/

output functions, click on the Download button to transfer the configuration to the

meter. When the configuration has been completely downloaded, power cycle the

meter to guarantee the changes take effect.

Filtering Tab

The Filtering tab contains several filter settings for the flow meter. These filters

can be adjusted to match response times and data “smoothing” performance to a

particular application.

Download

Cancel

File Open...

File Save...

System Configuration

Display

Basic Flow Filtering Output Security

%

Flow Filter (Damping):

%

80

Time Domain Filter:

8

Advanced Filter Settings:

Flow Filter Hystersis:

5

psec

Flow Filter Min Hystersis:

303

Bad Data Rejection:

3

Flow Filter Sensitivigy:

3

Factory Defaults

Figure 5.4 - Filtering Tab

Time Domain Filter (range 1-256) adjusts the number of raw data sets (the wave

forms viewed on the software Diagnostics Screen) that are averaged together.

Increasing this value provides greater damping of the data. Conversely, lowering this

value decreases the response time of the meter to changes in flow/energy rate.

Note: The meter completes a measurement in approximately 350-400 msec. The exact time is pipe

size dependant.