Installation guide, Part 3 - inputs/outputs, Operate in the shaded regions – Veris Industries FSRxxxx SERIES Install User Manual

Page 14

FSRxxxx SERIES

Z205739-0D

PAGE 14

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

05131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

90-265 VAC

AC Neutral

Control 1

Control 2

Frequency Out

4-20 mA Out

Reset Total

Signal Gnd.

Meter Power

Loop

Resistance

Signal Ground

7 VDC

Drop

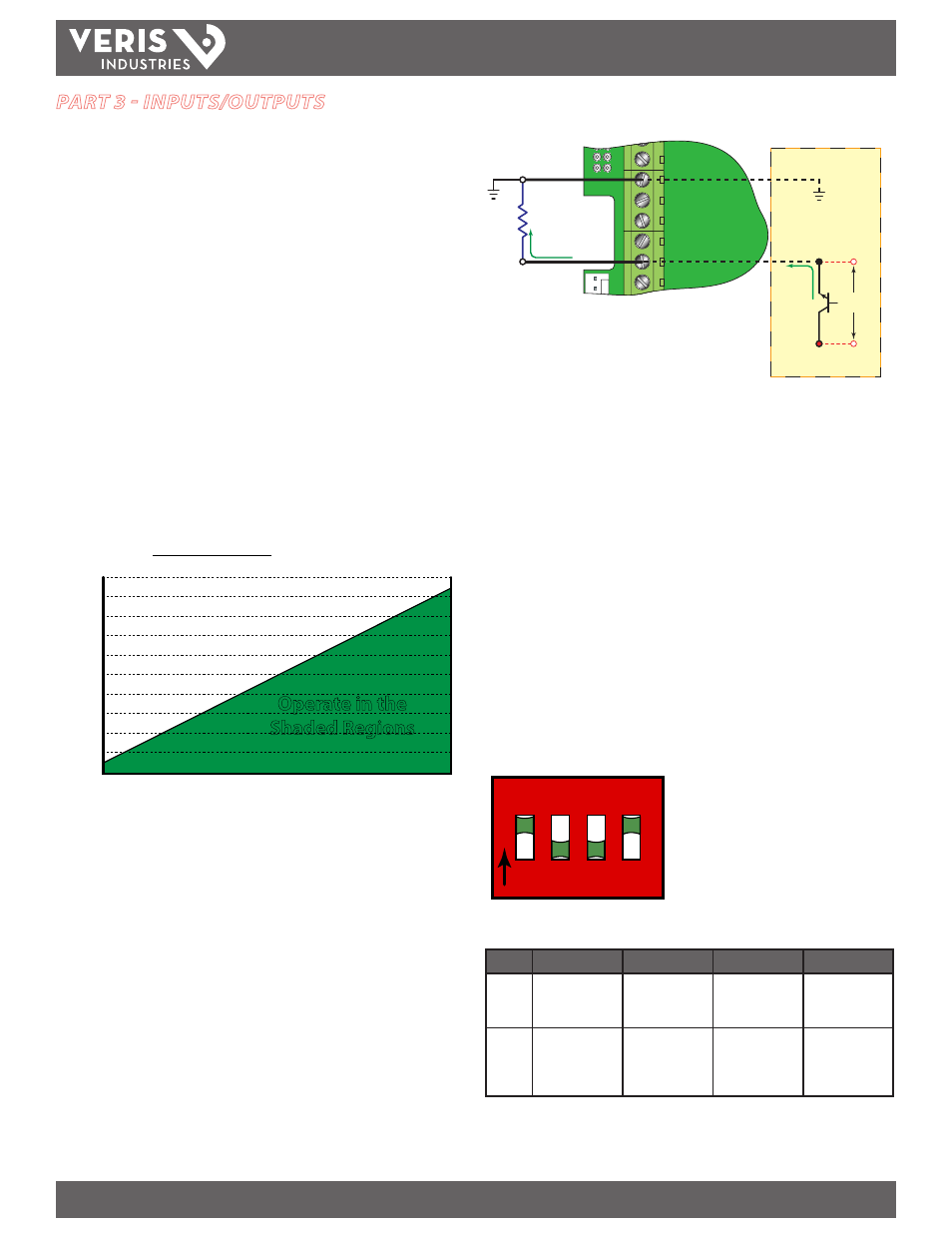

Figure 3.2 - 4-20 mA Output

The 4-20 mA output signal is available between the 4-20 mA Out and Signal Gnd.

terminals as shown in Figure 3.2.

Control Outputs

Two independent open collector transistor outputs are included with the flow meter.

Each output can be configured for one of the following four functions:

Rate Alarm

Signal Strength Alarm

Totalizing/Totalizing Pulse

Errors

None

Both control outputs are rated for a maximum of 100 mA and 10 to 28 VDC. A pull-up

resistor can be added externally or an internal 10 kΩ pull-up resistor can be selected

using DIP switches on the power supply board.

1 2 3 4

O

N

Figure 3.3 - Switch Settings

Switch

S1

S2

S3

S4

On

Control 1 pull-up;

Resistor IN circuit

Control 2 pull-up;

Resistor IN circuit

Frequency output

pull-up;

Resistor IN circuit

Square wave

output

Off

Control 1 pull-up;

Resistor OUT OF

circuit

Control 2 pull-up;

Resistor OUT OF

circuit

Frequency output

pull-up;

Resistor OUT OF

circuit

Simulated turbine

output

Table 3.1 - DIP Switch Functions

PART 3 - INPUTS/OUTPUTS

General

The FSR1 is available in two configurations: the flow model and the energy model.

The flow model is equipped with a 4-20 mA output, two open collector outputs, a

rate frequency output, and RS-485 communications using the Modbus RTU command

set. The energy version has inputs for two 1,000 Ω RTD sensors in place of the rate

frequency and alarm outputs. This version allows the measurement of pipe input and

output temperatures for calculating energy usage calculations.

4-20 mA Output

The 4-20 mA output interfaces with most recording and logging systems by

transmitting an analog current signal that is proportional to system flow rate. The

4-20 mA output is internally powered (current sourcing) and can span negative to

positive flow/energy rates.

For AC powered units, the 4-20 mA output is driven from a +15 VDC source located

within the meter, isolated from earth ground connections. The AC powered model

accommodates loop loads up to 400 Ω. DC powered meters utilize the DC power

supply voltage to drive the current loop. The current loop is not isolated from DC

ground or power. Figure 3.1 shows graphically the allowable loads for various input

voltages. The combination of input voltage and loop load must stay within the

shaded area of Figure 3.1.

200

100

300

400

500

600

700

800

900

1000

1100

10

12

14

16

18

20

22

24

26

28

Supply Voltage (VDC)

Lo

op L

oad (

O

hms)

Operate in the

Shaded Regions

Supply Voltage - 7 VDC

0.02

= Maximum Loop Resistance

Figure 3.1 - Allowable Loop Resistance (DC Powered Units)