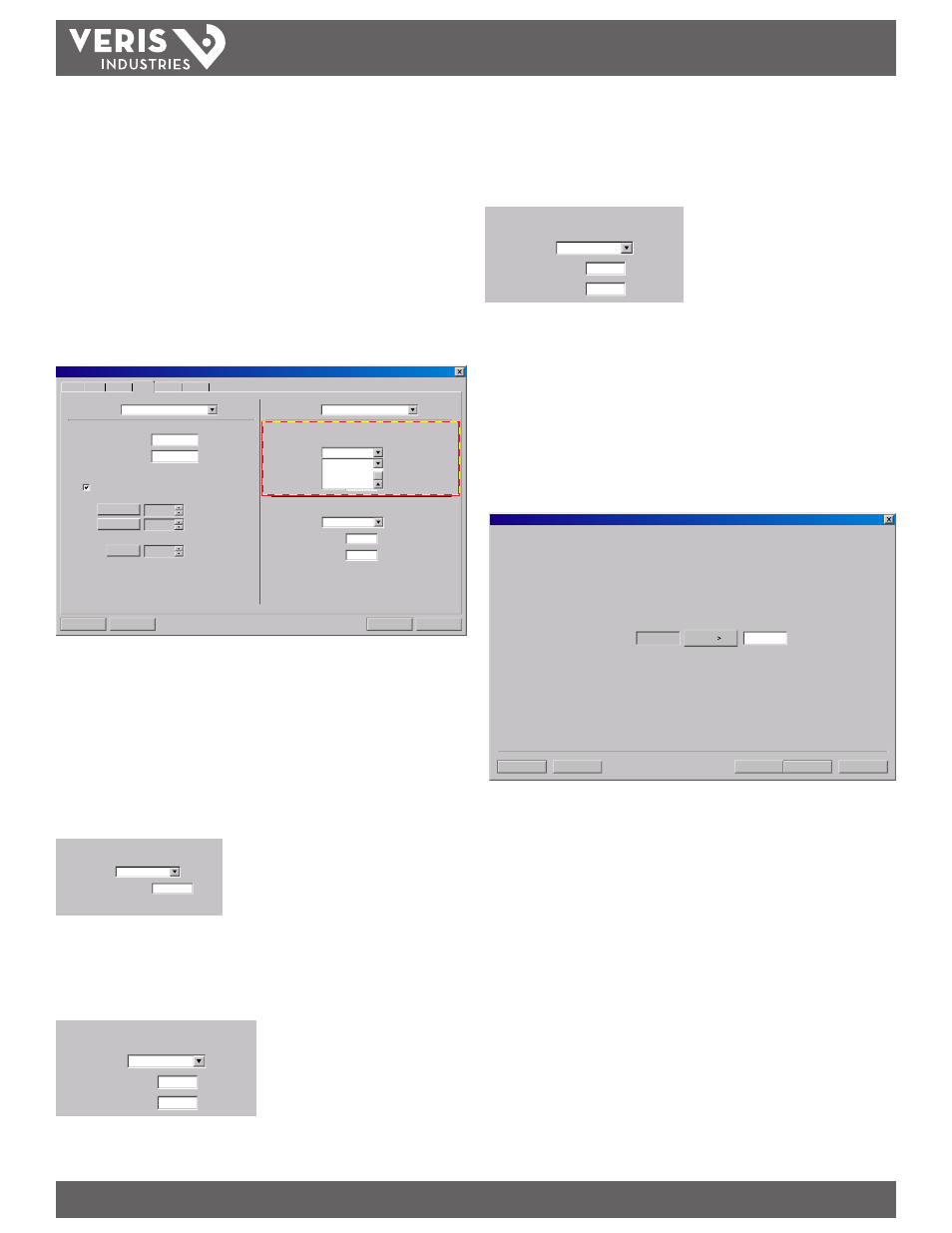

Installation guide, Setting zero and calibration, Figure 5.7 - channel 2 output choices – Veris Industries FSRxxxx SERIES Install User Manual

Page 33: Figure 5.8 - calibration page 1 of 3

FSRxxxx SERIES

Z205739-0D

PAGE 33

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

05131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

Channel 2 - Control Output Configuration [FSR1 Only]

Two independent open collector transistor outputs are included with the non-BTU

flow meter. Each output can be configured independently to “Alarm” for one of the

following. See Alarm Output in Part 3 for output details.

None

Batch / Total

Flow

Signal Strength

Errors

Download

Cancel

File Open...

File Save...

System Configuration

Display

Basic

Flow Filtering Output Security

Control Outputs

Channel 2:

50

Off <

Gal/M

350

On>

Gal/M

Mode: Flow

Control 1

50

Off <

Gal/M

350

On>

Gal/M

Mode: Flow

Mode: None

Control 2

4-20mA / Frequency

Channel 1:

0

Flow at 4mA / 0Hz:

Gal/M

400

Flow at 20mA / 1KHz:

Gal/M

Calibration/Test

Test

Calibration

4 mA

20 mA

32

3837

Test

4

Flow

Batch/Total

Flow

Sig Strength

Errors

Control Outputs

Channel 2:

Figure 5.7 - Channel 2 Output Choices

None: All alarm outputs are disabled

Batch / Total: Multiplier (Value)

This is the value to which the totalizer accumulates before actuating the control pulse

output and repeating the accumulation. This value includes any exponents that were

entered in the BSC MENU as TOTAL E. See Alarm Output in Part 3

50

Multiplier:

Mode:

Batch/Total

Control 1

Flow

ON (Value): Sets value at which the alarm output will switch from OFF to ON

OFF (Value): Sets value at which the alarm output will switch from ON to OFF

50

Off <

Gal/M

350

On>

Gal/M

Mode:

Flow

Control 1

Signal Strength

ON (Value) : Sets value at which the alarm output will turn ON

OFF (Value): Sets value at which the alarm output will turn OFF

Off <

On>

Mode:

Sig Strength

Control 1

Errors

Alarm outputs on any error condition. See Error Table in the Appendix of this manual.

Setting Zero and Calibration

The software utility contains a powerful multi-point calibration routine that can

be used to calibrate the flow meter to a primary measuring standard in a particular

installation. To initialize the three-step calibration routine, click on the Calibration

button located on the top of the Data Screen. The display shown in Figure 5.8 will

appear.

Next>

Cancel File Open... File Save... Calibration (Page 1 of 3) - Zero Flow Set -- -0.88 -0.43 Current Delta T: 1. Make sure flow is at zero. 2. Wait for flow to stabilize. 3. Press . Figure 5.8 - Calibration Page 1 of 3 The first screen (Page 1 of 3) , establishes a baseline zero flow rate measurement for Because every flow meter installation is slightly different and sound waves can To zero the flow meter: 1) Establish zero flow in the pipe (ensure that the pipe is full of fluid, turn off 2) Click the Set button. 3) Click the Next button when prompted, then click the Finish button on the The zeroing process is essential in systems using the FST1, FST2, and FST3

the instrument.

travel in slightly different ways through these various installations, it is important to

remove the zero offset at zero flow to maintain the meters accuracy. A provision is

made using this entry to establish “Zero” flow and eliminate the offset.

all pumps, and close a dead-heading valve). Wait until the delta-time interval

shown in “Current Delta T” is stable (and typically very close to zero).

calibration screen.

transducer sets to ensure the best accuracy.