Sitrans p measuring instruments for pressure – Siemens SITRANS P User Manual

Page 65

SITRANS P measuring instruments for pressure

Transmitters for gage, absolute and differential pressure, flow and level

DS III, DS III PA and DS III FF series

Technical description

2/65

Siemens FI 01 · 2009

2

■

Function

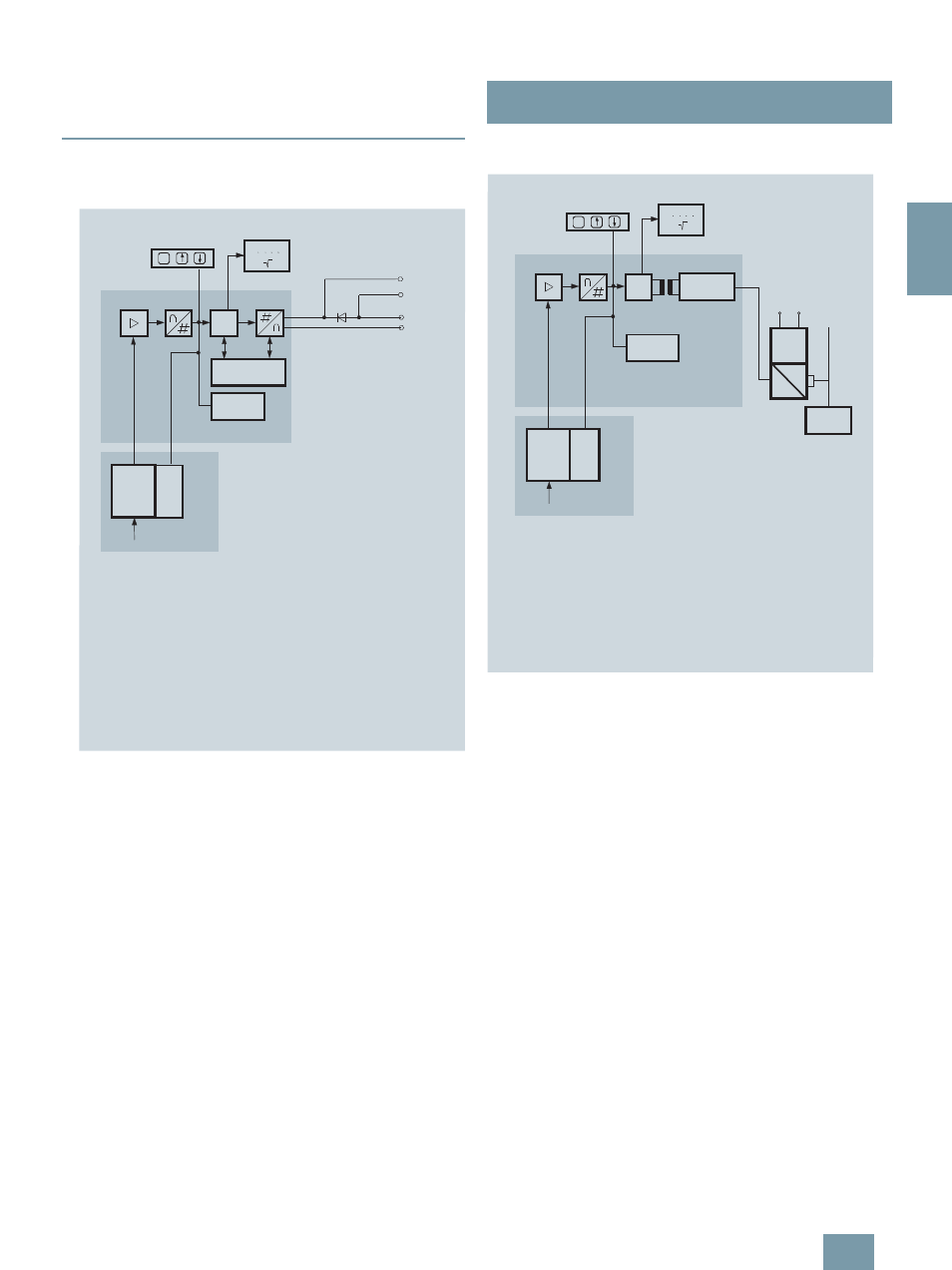

Operation of the electronics with PROFIBUS PA communica-

tion

Function diagram of the electronics

The bridge output voltage created by the sensor (1, Figure

"Function diagram of the electronics") is amplified by the instru-

ment amplifier (2) and digitized in the analog-to-digital converter

(3). The digital information is evaluated in a microcontroller, its

linearity and temperature response corrected, and converted in

a digital-to-analog converter (5) into an output current of 4 to

20 mA.

The diode circuit (10) protects against incorrect polarity.

The data specific to the measuring cell, the electronics data, and

the parameter data are stored in the two non-volatile memories

(6). The one memory is coupled to the measuring cell, the other

to the electronics. As the result of this modular design, the elec-

tronics and the measuring cell can be replaced separately from

each other.

Using the 3 input keys (8) you can parameterize the pressure

transmitter directly at the point of measurement. The input keys

can also be used to control the view of the results, the error mes-

sages and the operating modes on the digital display (9).

The HART modem (7) permits parameterization using a protocol

according to the HART specification.

The pressure transmitters with spans

≤ 63 bar measure the input

pressure compared to atmosphere, transmitters with spans

≥ 160 bar compared to vacuum.

Operation of the electronics with PROFIBUS PA communica-

tion

Function diagram of the electronics

The bridge output voltage created by the sensor (1, Figure

"Function diagram of the electronics") is amplified by the instru-

ment amplifier (2) and digitized in the analog-to-digital converter

(3). The digital information is evaluated in the microcontroller, its

linearity and temperature response corrected, and provided on

the PROFIBUS PA through an electrically isolated PA interface

(7).

The data specific to the measuring cell, the electronics data, and

the parameter data are stored in the two non-volatile memories

(6). The first memory is linked with the measuring cell, the sec-

ond with the electronics. This modular design means that the

electronics and the measuring cell can be replaced separately

from one another.

Using the three input keys (8) you can parameterize the pressure

transmitter directly at the point of measurement. The input keys

can also be used to control the view of the results, the error mes-

sages and the operating modes on the digital display (9).

The results with status values and diagnostic values are trans-

ferred by cyclic data transmission on the PROFIBUS PA. Param-

eterization data and error messages are transferred by acyclic

data transmission. Special software such as SIMATIC PDM is re-

quired for this.

I

A

, U

H

5

6

7

8

P

e

1

4

3

2

C

m

M

10

0 0 00 0

0 0

9

6

1

Measuring cell sensor

2

Instrument amplifier

3

Analog-to-digital converter

4

Microcontroller

5

Digital-to-analog converter

6

One non-volatile memory each in the measuring cell and electronics

7

HART interface

8

Three input keys (local operation)

9

Digital display

10 Diode circuit and connection for external ammeter

I

A

Output current

U

H

Power supply

P

e

Input variable

Sensor

EEPROM

EEPROM

HART interface

Electronics

Measuring cell

6

8

pe

1

2

C

m

M

0 0 00 0

0 0

EEPROM

EEPROM

9

6

3

4

5

7

10

12

11

1

Measuring cell sensor

2

Instrument amplifier

3

Analog-to-digital converter

4

Microcontroller

5

Electrical isolation

6

One non-volatile memory

each in the measuring cell

and electronics

7

PROFIBUS-PA interface

Sensor

Electronics

Measuring cell

PA

interface

Bus-

Master

Power

supply

unit

Coup-

ler

Power supply

PROF

IBU

S-DP

PROF

IBU

S-PA

8

Three input keys

(local operation)

9

Digital display

10 Power supply

11 DP/PA coupler or link

12 Bus master

p

e

Input variable

© Siemens AG 2008