Sitrans p measuring instruments for pressure – Siemens SITRANS P User Manual

Page 51

SITRANS P measuring instruments for pressure

Transmitters for gage pressure for the paper industry

SITRANS P300 and DS III series

with PMC connection – Technical description

2/51

Siemens FI 01 · 2009

2

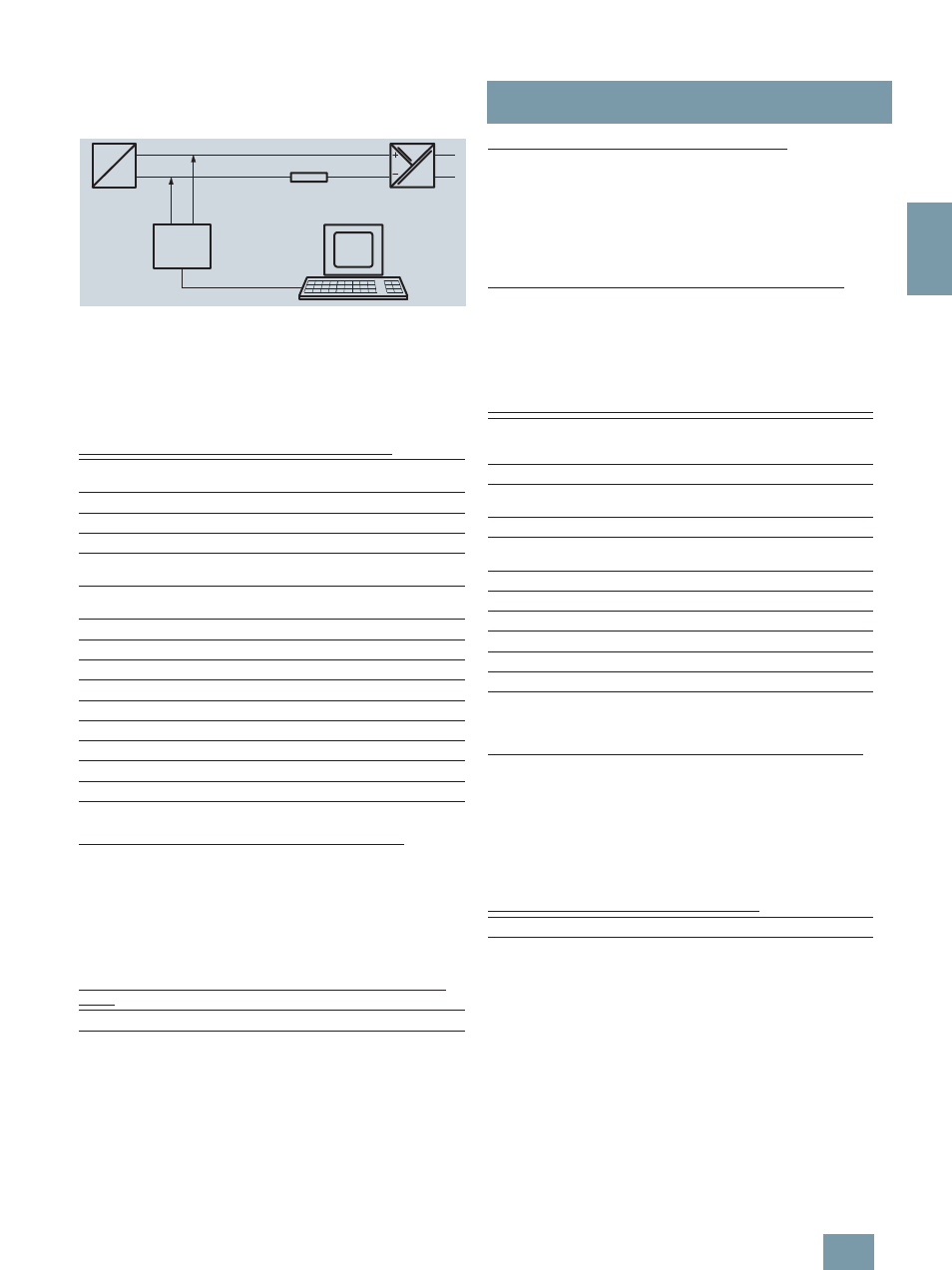

HART communication between a PC communicator and a pressure

transmitter

When parameterizing with a PC, the connection is made through

a HART modem.

The signals needed for communication in conformity with the

HART 5.x or 6.x protocols are superimposed on the output cur-

rent using the Frequency Shift Keying (FSK) method.

Adjustable parameter DS III HART and P300 HART

Diagnostic functions for DS III HART and P300 HART

• Zero correction display

• Event counter

• Limit transmitter

• Saturation alarm

• Slave pointer

• Simulation functions

• Maintenance timer

Available physical units of display for DS III HART and P300

HART

Parameterization through PROFIBUS PA interface

Fully digital communication through PROFIBUS PA, profile 3.0, is

particularly user-friendly. The PROFIBUS puts the DS III PA is in

connection with a process control system, e.g. SIMATIC PSC 7.

Communication is possible even in a potentially explosive envi-

ronment.

For parameterization through PROFIBUS you need suitable soft-

ware, e.g. SIMATIC PDM (Process Device Manager).

Parameterization through FOUNDATION Fieldbus Interface

Fully digital communication through FOUNDATION Fieldbus is

particularly user-friendly. Through the FOUNDATION Fieldbus

the DS III FF is connected to a process control system. Commu-

nication is possible even in a potentially explosive environment.

For parameterization through the FOUNDATION Fieldbus you

need suitable software, e.g. National Instruments Configurator.

Adjustable parameters for DS III PA and FF and P300 PA and FF

Diagnostic functions for DS III PA and FF and P300 PA and FF

• Event counter

• Slave pointer

• Maintenance timer

• Simulation functions

• Display of zero correction

• Limit transmitter

• Saturation alarm

Physical dimensions available for the display

Parameters

Input keys

HART com-

munication

Start of scale

x

x

Full-scale value

x

x

Electrical damping

x

x

Start-of-scale value without application

of a pressure ("Blind setting")

x

x

Full-scale value without application of a

pressure ("Blind setting")

x

x

Zero adjustment

x

x

Current transmitter

x

x

Fault current

x

x

Disabling of keys, write protection

x

x

1)

1)

Cancel apart from write protection

Type of dimension and actual dimension x

x

Characteristic (linear)

x

x

Input of characteristic

x

Freely-programmable LCD

x

Diagnostics functions

x

Physical variable

Physical dimensions

Pressure (setting can also be

made in the factory)

Pa, MPa, kPa, bar, mbar, torr, atm,

psi, g/cm

2

, kg/cm

2

, inH

2

O, inH

2

O

(4 °C), mmH

2

O, ftH

2

O (20 °C),

inHg, mmHg

Level (height data)

m, cm, mm, ft, in

Volume

m

3

, dm

3

, hl, yd

3

, ft

3

, in

3

, US gallon,

lmp, gallon, bushel, barrel, barrel

liquid

Mass

g, kg, t, lb, Ston, Lton, oz

Temperature

K, °C, °F, °R

Miscellaneous

%, mA

transmitter

SITRANS P

Power supply

HART

modem

PC or

laptop

RS 232

230 ... 500 W

Adjustable parameters

Input keys

PROFIBUS PA and

FOUNDATION

Fieldbus interface

Electrical damping

x

x

Zero adjustment (correction of

position)

x

x

Key and/or function disabling

x

x

Source of measured-value dis-

play

x

x

Physical dimension of display

x

x

Position of decimal point

x

x

Bus address

x

x

Adjustment of characteristic

x

x

Input of characteristic

x

Freely-programmable LCD

x

Diagnostic functions

x

Physical variable

Physical dimensions

Pressure (setting can also be

made in the factory)

MPa, kPa, Pa, bar, mbar, torr, atm,

psi, g/cm

2

, kg/cm

2

, mmH

2

O,

mmH

2

O (4 °C), inH

2

O, inH

2

0

(4 °C), ftH

2

O (20 °C), mmHg, inHg

Level (height data)

m, cm, mm, ft, in, yd

Mass

g, kg, t, lb, Ston, Lton, oz

Volume

m

3

, dm

3

, hl, yd

3

, ft

3

, in

3

, US gallon,

lmp, gallon, bushel, barrel, barrel

liquid

Temperature

K, °C, °F, °R

Miscellaneous

%

© Siemens AG 2008