Sitrans p measuring instruments for pressure, Remote seals for transmitters and pressure gages, Technical description 2/157 – Siemens SITRANS P User Manual

Page 157

SITRANS P measuring instruments for pressure

Remote seals for transmitters and pressure gages

Technical description

2/157

Siemens FI 01 · 2009

2

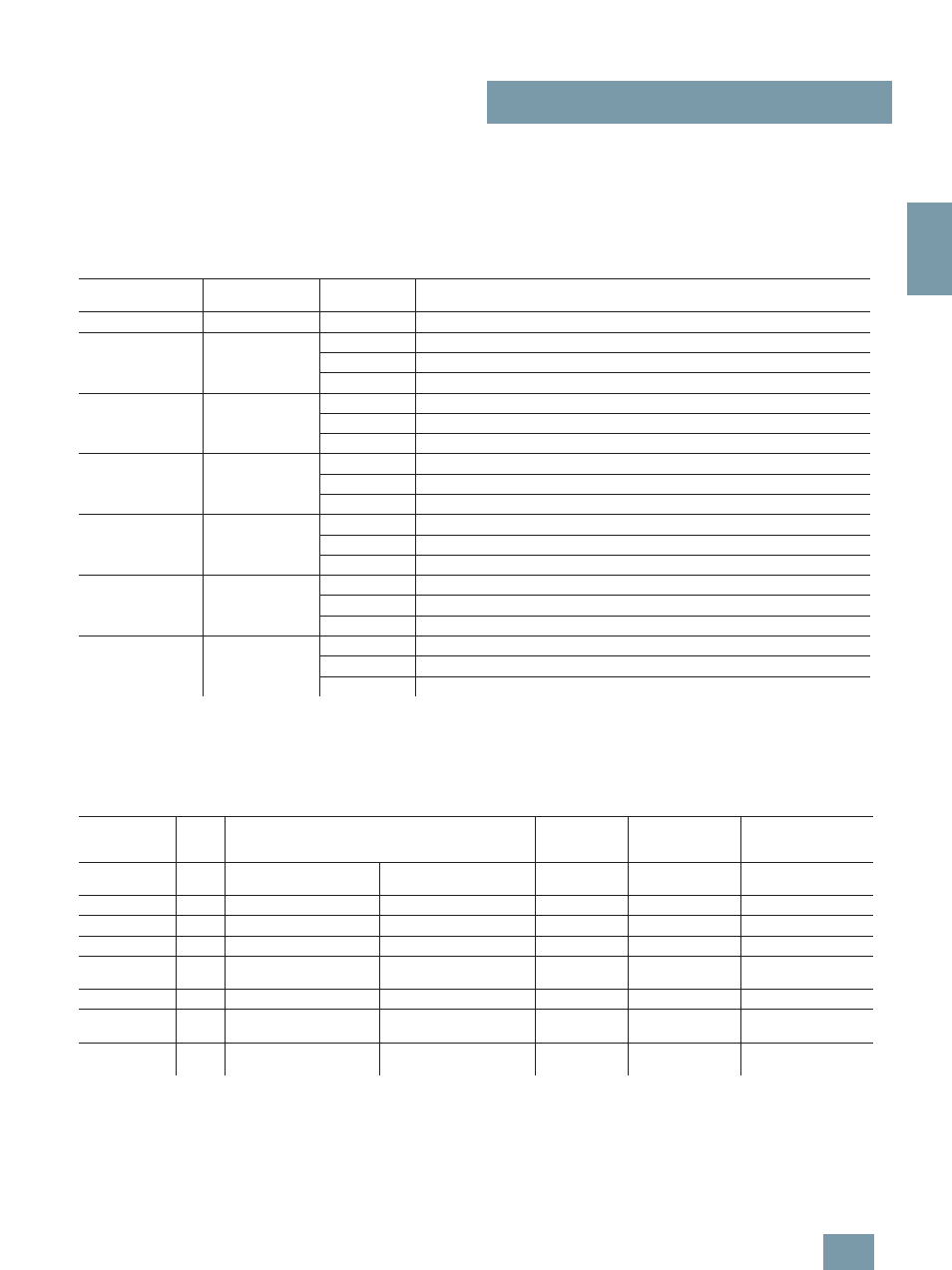

Response times

The values listed in the following table are the response times (in

seconds per meter of capillary) for a change in pressure which

corresponds to the set span.

The listed values must be multiplied by the respective length of

the capillary, or with transmitters for differential pressure and flow

by the total length of both capillaries.

The response times are independent of the set span within the

range of the respective transmitter. The response times are of in-

significant importance for spans above 10 bar (145 psi). The re-

sponse times of the pressure transmitters are not considered in

the table.

Technical data of filling liquids

When selecting the filling liquid, check that it is suitable with re-

spect to the permissible temperature of the medium and the pro-

cess pressure.

Also check the compatibility of the filling liquid with the mea-

sured medium. For example, only physiologically harmless filling

liquids may be used in the food industry.

Oxygen and chlorine are special cases of measured medium.

The liquid must not react with either of these two media or a leak-

ing remote seal may lead to an explosion or fire.

Filling liquid

Density

Temperature

on capillary

Response time in s/m (s/ft) with max. span of pressure transmitter

kg/dm

3

(lb/in

3

)

°C

(°F)

250 mbar

(3.63 psi)

600 mbar

(8.7 psi)

1600 mbar

(23.2 psi)

Silicone oil M5

0.914

(0.033)

+60

(140)

0.06

(0.018)

0.02

(0.006)

0.01

(0.003)

+20

(68)

0.11

(0.034)

0.02

(0.006)

0.02

(0.006)

- 20

(-4)

0.3

(0.091)

0.12

(0.037)

0.05

(0.015)

Silicone oil M50

0.966

(0.035)

+60

(140)

0.6

(0.183)

0.25

(0.076)

0.09

(0.027)

+20

(68)

0.61

(0.186)

0.26

(0.079)

0.1

(0.030)

- 20

(-4)

1.69

(0.515)

0.71

(0.216)

0.27

(0.082)

High-temperature oil

1.070

(0.039)

+60

(140)

0.14

(0.043)

0.06

(0.018)

0.02

(0.006)

+20

(68)

0.65

(0.198)

0.27

(0.082)

0.1

(0.030)

-10

(14)

3.96

(1.207)

1.65

(0.503)

0.62

(0.189)

Halocarbon oil

1.968

(0.071)

+60

(140)

0.07

(0.021)

0.03

(0.009)

0.01

(0.003)

+20

(68)

0.29

(0.088)

0.12

(0.037)

0.05

(0.015)

- 20

(-4)

2.88

(0.878)

1.2

(0.366)

0.45

(0.137)

Food oil (FDA listed)

0.920

(0.033)

+60

(140)

0.75

(0.229)

0.33

(0.101)

0.17

(0.052)

+20

(68)

4

(1.220)

1.75

(0.534)

0.67

(0.204)

- 20

(-4)

20

(6.100)

8.5

(2.593)

3.25

(0.991)

Glycerin/water

1.220

(0.044)

+60

(140)

0.13

(0.040)

0.05

(0.015)

0.02

(0.006)

+20

(68)

0.76

(0.232)

0.32

(0.098)

0.12

(0.037)

0

(32)

9.72

(2.963)

4.05

(1.234)

1.51

(0.460)

Filling liquid

Digit in

Order

No.

Permissible temperature of medium

Density at

20 °C (68 °F)

Viscosity at

20 °C (68 °F)

Coefficient of expan-

sion

p

abs

<

1 bar

(p

abs

<

14.5 psi)

p

abs

>

1 bar

(p

abs

>

14.5 psi)

°C

(°F)

°C

(°F)

kg/dm

3

(lb/in

3

) m

2

/s

⋅10

6

(ft

2

/s

⋅10

6

) 1/°C

(1/°F)

Silicone oil M5

1

-60 ... +80

(-76 ... +176)

-90 ... +180 (-130 ... +356) 0.914

(0.03)

4

(43)

0.00108

(0.00060)

Silicone oil M50

2

-40 ... +150 (-40 ... +302)

-40 ... +250 (-40 ... +482)

0.96

(0.03)

50

(538)

0.00104

(0.00058)

High-tempera-

ture oil

3

-10 ... +200 (+14 ... +392) -10 ... +350 (+14 ... +662)

1.07

(0.04)

39

(420)

0.00080

(0.00044)

Halocarbon oil

4

-40 ... +80

(-40 ... +176)

-40 ... +175 (-40 ... +347)

1.968

(0.07)

14

(151)

0.00086

(0.00048)

Glycerin/water

6

Not possi-

ble

Not possible

-10 ... +120 (+14 ... +248)

1.22

(0.04)

88

(947)

0.00050

(0.00028)

Food oil (FDA

listed)

7

-20 ... +160 (-4 ... +320)

-20 ... +200 (-4 ... +392)

0.92

(0.03)

10

(107)

0.00080

(0.00044)

© Siemens AG 2008