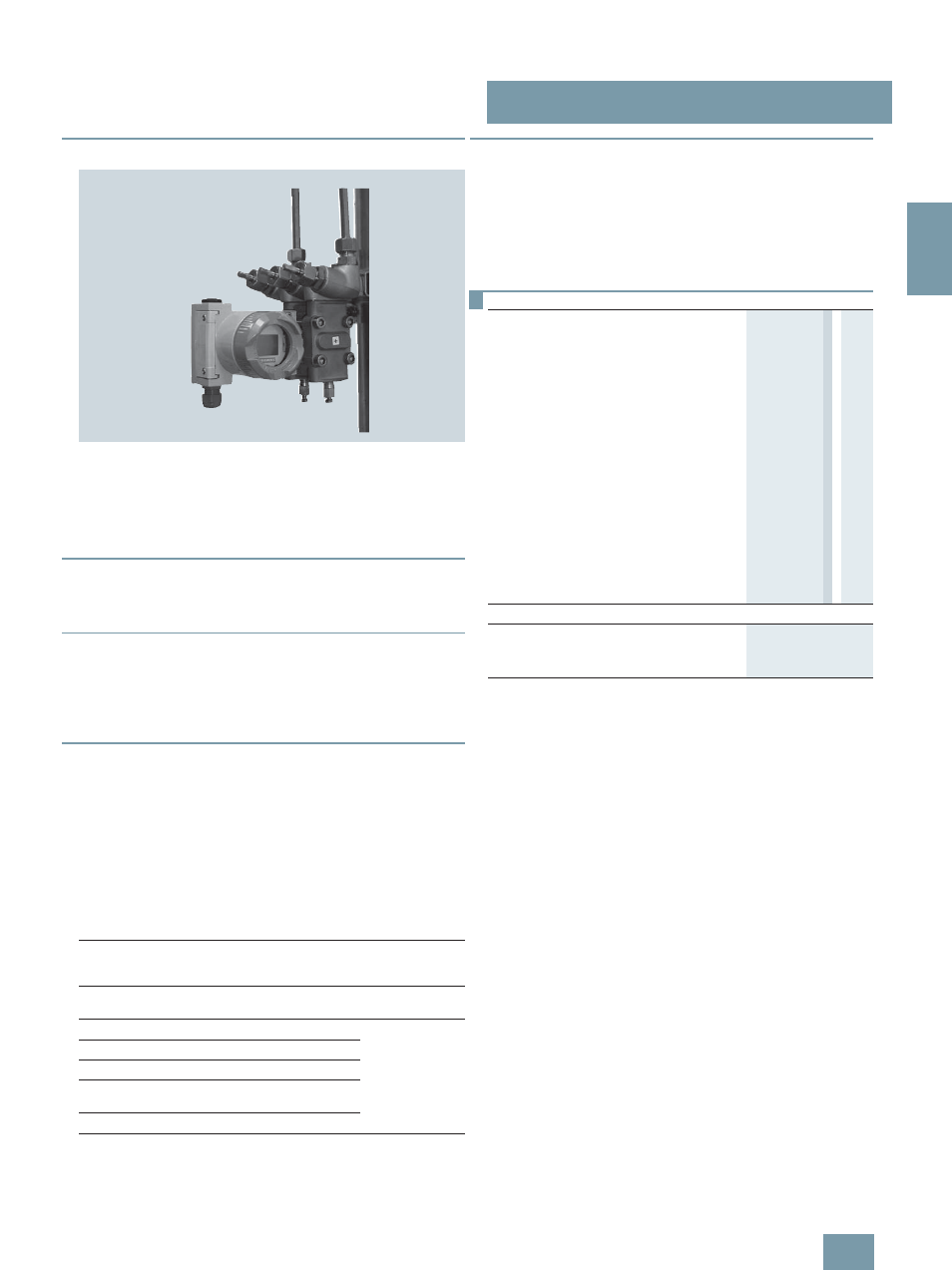

Way valve manifold dn 8, Sitrans p measuring instruments for pressure – Siemens SITRANS P User Manual

Page 209

SITRANS P measuring instruments for pressure

Fitttings - Shut-off valves for differential pressure transmitters

3-way valve manifold DN 8

2/209

Siemens FI 01 · 2009

2

■

Overview

The 3-way valve manifold DN 8 (7MF9416-1../-2..) is for pressure

transmitters for differential pressure. It is used to shut off and

blow out differential pressure lines and to test the pressure trans-

mitter zero.

In the designs with a test connection, a test device can be con-

nected to test the pressure transmitter characteristic.

■

Benefits

• For aggressive and non-aggressive liquids and gases

• The maximum working pressure is 420 bar.

■

Application

The 3-way valve manifold is available in versions for aggressive

and non-aggressive liquids and gases.

Mounting plates are available for wall mounting, for securing to

mounting racks or for pipe mounting.

■

Design

For the process connection on the version for non-aggressive

media it is possible to choose between a pipe union with ferrule

and welding pins.

The version for aggressive media always has a pipe union with

ferrule.

Both versions are available optionally with a test connection

M20x1.5.

The valves have an internal spindle thread.

Materials used

■

Function

The 3-way valve manifold DN 8 performs two functions as stan-

dard:

• Shutting off the differential pressure lines

• Checking the pressure transmitter zero

All versions are also available with a test connection, to which a

test device for checking the pressure transmitter characteristic

can be connected.

For non-aggressive liquids and

gases

For aggressive

liquids and

gases

Component Material

Mat. No.

Material

Mat.

No.

Housing

P250GH

1.0460

X 6

CrNiMoTi

17 12 2

1.4571/

316Ti

Head parts

C 35

1.0501

Spindles

X 12 CrMoS 17

1.4104

Cones

X 35 CrMo 17 hard-

ened and tempered

1.4122

Valve seats

X 6 CrNiMoTi 17 12 2

1.4571/316Ti

Packings

PTFE

-

PTFE

-

Selection and Ordering data

Order No.

3-way valve manifold DN 8

7 M F 9 4 1 6 -

7 7

A

for flanging to pressure transmitters for differ-

ential pressure, max. working pressure

420 bar, (order accessory set and mounting

plate with Order code), without certificate

for non-aggressive liquids and gases

procedss connection: Pipe union with ferrule

• without test connection

1 B

• with test connection

1 C

for non-aggressive liquids and gases

procedss connection: Welding pin Ø 14 x 2.5

• without test connection

2 C

• with test connection

2 D

for aggressive liquids and gases

process connection: Pipe union with ferrule

• without test connection

1 D

• with test connection

1 E

Accessories

Factory test certificate EN 10204–2.2

7MF9000-8AB

Material acceptance test certificate

EN 10204-3.1

7MF9000-8AD

© Siemens AG 2008