Sitrans p measuring instruments for pressure – Siemens SITRANS P User Manual

Page 217

SITRANS P measuring instruments for pressure

Fitttings - Shut-off valves for differential pressure transmitters

2-, 3- and 5-spindle valve manifolds

for installing in protective boxes

2/217

Siemens FI 01 · 2009

2

■

Accessories

Accessory set for 2-, 3- and 5-spindle valve manifolds (Con-

nection between manifold and transmitter)

2-spindle valve manifold DN 5 with flange connection

• F32: 2 screws 7/16 20 UNF x 2 inch to ASME B 18.2.1,

1 O Ring (FPM90)

• F35: 2 screws 7/16 20 UNF x 2 inch to ASME B 18.2.1,

1 flat-gasket

• F12: 2 screws M10x50 to DIN EN 24014, 2 washers,

1 O-ring (FPM90)

• F15: 2 screws M10x50 toDIN EN 24014, 2 washers,

1 flat gasket

3-spindle and 5-way valve manifold DN 5

• F34: 4 screws 7/16 20 UNF x 2 inch toASME B 18.2.1,

2 O-rings (FPM90)

• F36: 4 screws 7/16 20 UNF x 2 inch toASME B 18.2.1,

2 flat-gaskets

• F14: 4 screws M10x50 toDIN EN 24014, 4 washers,

2 O-rings (FPM90)

• F16: 4 screws M10x50 toDIN EN 24014, 4 washers,

2 flat-gaskets

Washers Ø 10,5 to DIN 125

Flat-gaskets made of PTFE, max. 420 bar, 80 °C

O-ring to DIN 3771, 20 x 2,65 - S - FPM90; max.420 bar, 120 °C

Note:

Flange connections with M10 screws only permissible up to

PN 160!

Mounting bracket for wall mounting or for securing to

mounting rack

With bolds for mounting on valve manifold

• M14: For 2-spindle valve manifold DN 5

• M17: For 3-spindle valve manifold DN 5

• M18: For 5-spindle valve manifold DN 5

Mounting clips (2 off)

• M16: For securing the mounting brackets M14, M17 and M18

to pipe

Valve manifold 100 bar, suitable for oxygen

• S12: For 2-spindle valve manifold DN 5

• S13: For 3-spindle valve manifold DN 5

• S14: For 5-spindle valve manifold DN 5

■

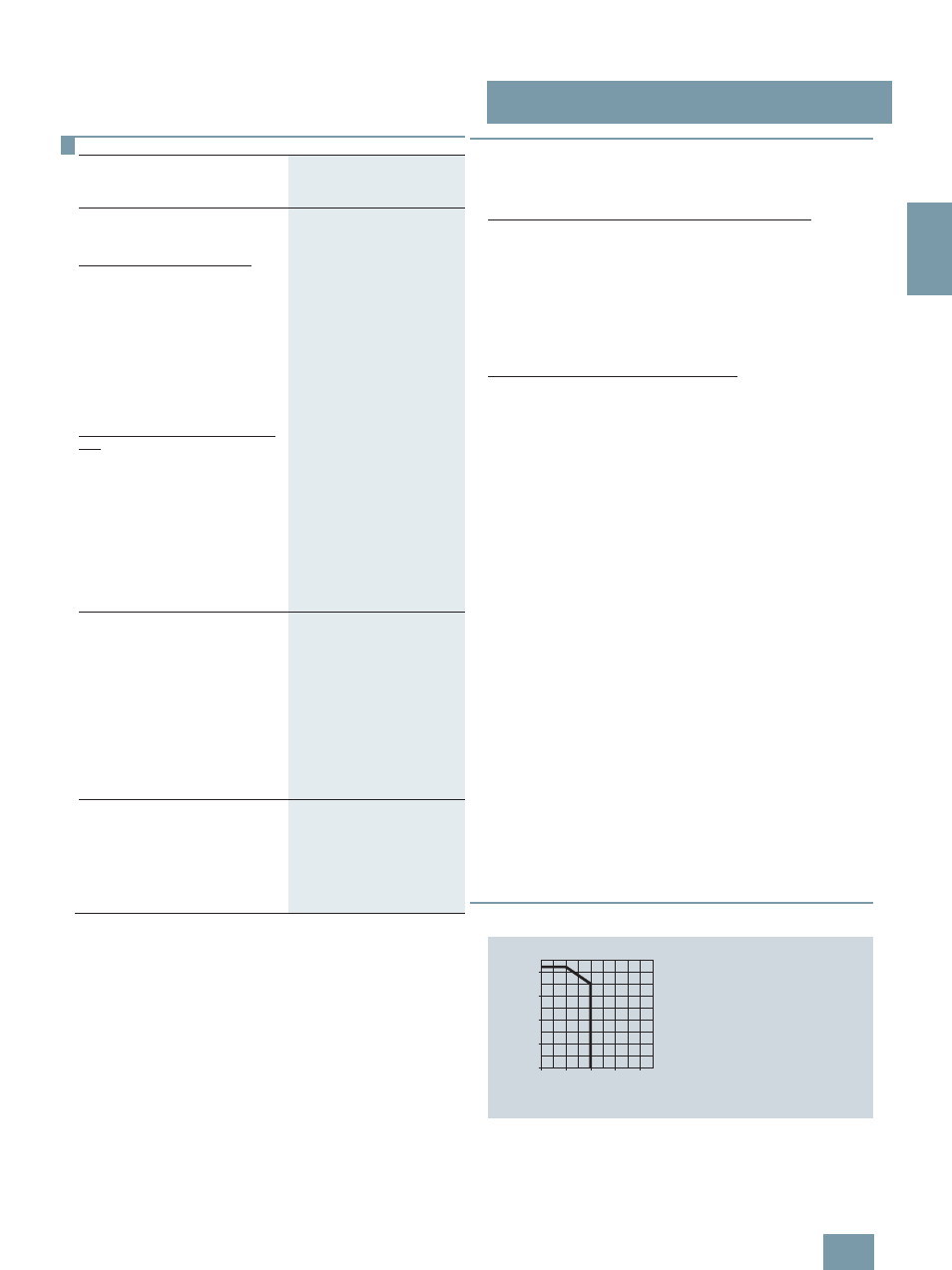

Characteristic curves

Permissible operating pressure as a function of the permissible operating

temperature

Accessory set to DIN

(connection between valve manifold

and pressure transmitter)

for valve manifold 7MF9412–1C.

2x screws M10x50 to DIN EN 24014;

chromized steel

2x washers Ø 10.5 mm to DIN 125;

1x O-ring to DIN 3771,

20 x 2.65 - S - FPM90, max. permiss-

ble 420 bar, 120 °C

2)

F12

7MF9412-6AA

2x screws M10x50 to DIN EN 24014;

chromized steel

2x washers Ø 10.5 mm to DIN 125;

1x gasket made of PTFE,

max. permissible 420 bar, 80 °C

2)

F15

7MF9412-6BA

for valve manifold 7MF9412–1D and

-1E.

4x screws M10x50 to DIN EN 24014;

chromized steel

4x washers Ø 10.5 mm to DIN 125;

2x O-rings to DIN 3771,

20 x 2.65 - S - FPM90, max. permiss-

ble 420 bar, 120 °C

2)

F14

7MF9412-6EA

4x screws M10x50 to DIN EN 24014;

chromized steel

4x washers Ø 10.5 mm to DIN 125;

2x flat gaskets made of PTFE,

max. permissible 420 bar, 80 °C

2)

F16

7MF9412-6FA

Mounting bracket

required for wall mounting or for

securing to mounting rack, with bolts

for mounting on valve manifold

• for valve manifolds 7MF9412-1B.

and -1C.

M14

7MF9006-6LA

• for valve manifold 7MF9412-1D.

M17

7MF9006-6NA

• for valve manifold 7MF9412-1E.

M18

7MF9006-6PA

Mounting clip

2 off, to secure mounting bracket

to pipe

M16

7MF9006-6KA

Valve manifold 100 bar

suitable for oxygen

• for valve manifolds 7MF9412-1B.

and -1C.

S12

• for valve manifold 7MF9412-1D.

S13

• for valve manifold 7MF9412-1E.

S14

1)

When ordering accessory set or mounting together with the valve

manifolds, please use Order code; otherwise use Order No.

2)

Flange connections with M10 screws only permissible up to PN 160!

Selection and Ordering data

Order code

Order No.

Further designs

1)

Please add "-Z" to Order No. and

specify Order code.

0

100

200

300

400

bar

°C

0 100 200 300 400

Op

era

tin

g

pre

ss

ure

Operating temperature

420 bar at 120 °C

350 bar at 200 °C

© Siemens AG 2008