Sitrans p measuring instruments for pressure – Siemens SITRANS P User Manual

Page 108

SITRANS P measuring instruments for pressure

Transmitters for gage, absolute and differential pressure, flow and level

DS III series

for differential pressure and flow

2/108

Siemens FI 01 · 2009

2

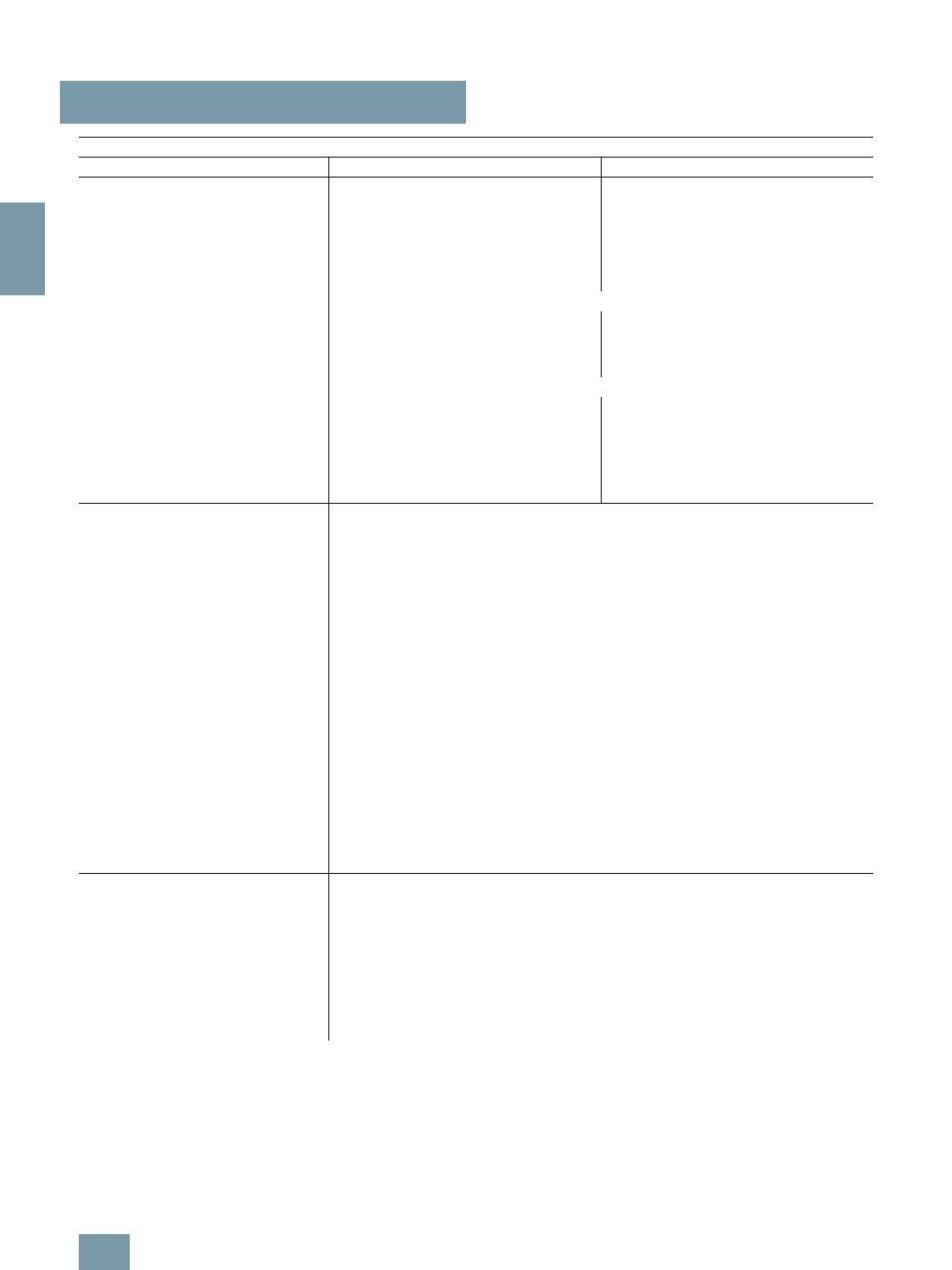

• Square-root characteristic (flow 25 ... 50%)

≤ 0,2

- r

≤ 10

≤ 0,2%

-

- 10 < r

≤ 30

≤ 0,4%

-

Long-term drift (temperature change

± 30 °C

(

± 54 °F))

≤ (0.25 ⋅ r)% every 5 years

static pressure max. 70 bar g (1015 psi g)

≤ (0.25% every 5 years

static pressure max. 70 bar g (1015 psi g)

• 20 mbar (0.29 psi)-measuring cell

≤ (0.2 ⋅ r) per year

≤ 0.2 per year

Influence of ambient temperature

• at -10 ... +60 °C (14 ... 140 °F)

≤ (0.08 ⋅ r + 0.1)%

≤ 0,3%

• at -40 ... -10 °C and +60 ... +85 °C

(-40 ... +14 °F and 140 ... 185 °F)

≤ (0.1 ⋅ r + 0.15)%/10 K

(Twice the value with 20-mbar (0.29 psi)

measuring cell)

≤ 0.25%/10 K

Influence of static pressure

• on the zero point

≤ (0.15 ⋅ r)% per 100 bar (1450 psi)

≤ 0.15% je 100 bar (1450 psi)

- 20 mbar (0.29 psi)-measuring cell

≤ (0.15 ⋅ r)% per 32 bar (464 psi)

≤ 0.15% je 32 bar (464 psi)

• on the span

≤ 0.2% je 100 bar (1450 psi)

-

- 20 mbar (0.29 psi)-measuring cell

≤ 0.2% je 32 bar (464 psi)

-

Measured Value Resolution

-

3

⋅ 10

-5

of nominal measuring range

Rated operating conditions

Degree of protection (to EN 60529)

IP65

Process temperature

• Measuring cell with silicone oil filling

-40 ... +100 °C (-40 ... +212 °F)

• Measuring cell with inert filling liquid

-20 ... +100 °C (-4 ... +212 °F)

• In conjunction with dust explosion protec-

tion

-20 ... +60 °C (-4 ... +140 °F)

Ambient conditions

• Ambient temperature

- Digital indicators

-30 ... +85 °C (-22 ... +185 °F)

• Storage temperature

-50 ... +85 °C (-58 ... +185 °F)

• Climatic class

- Condensation

Permissible

• Electromagnetic compatibility

- Emitted interference and interference

immunity

To EN 61326 and NAMUR NE 21

Material of the mounting bracket

• Steel

Sheet steel, Mat. No. 1.0330, chrome-plated

• Stainless steel

Stainless steel, Mat. No. 1.4301 (SS304)

Design

Weight (without options)

≈ 4.5 kg (≈ 9.9 lb)

Housing material

Poor in copper die-cast aluminium, GD-AlSi12 or stainless steel precision casting, mat. No. 1.4408

Wetted parts materials

• Seal diaphragm

Stainless steel, mat. No. 1.4404/316L or Hastelloy C276, mat. No. 2.4819, Monel, mat. No. 2.4360,

tantalum or gold

Measuring cell filling

Silicone oil or inert filling liquid (max. 160 bar (2320 psi g) with oxygen measurement)

Process connection

Female thread ¼-18 NPT and flange connection with mounting thread M10 to DIN 19213 or

7

/

16

-20 UNF to EN 61518

SITRANS P, DS III series, for differential pressure and flow

HART

PROFIBUS PA or FOUNDATION Fieldbus

© Siemens AG 2008