Sitrans p measuring instruments for pressure – Siemens SITRANS P User Manual

Page 26

SITRANS P measuring instruments for pressure

Transmitters for food, pharmaceuticals and biotechnology

SITRANS P Compact

for gage and absolute pressure

2/26

Siemens FI 01 · 2009

2

F) Subject to export regulations AL: 9I999, ECCN: N.

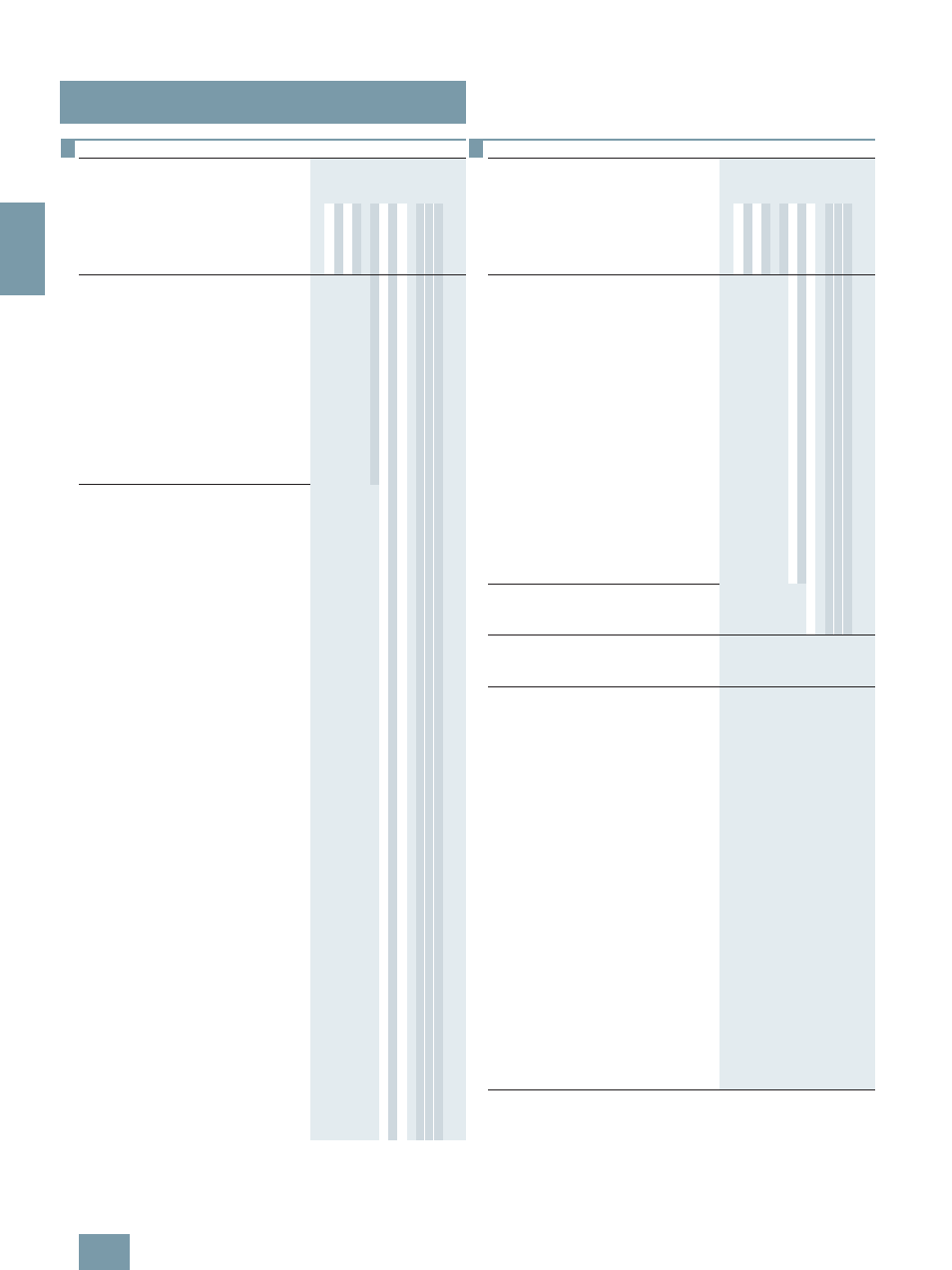

Selection and Ordering data

Order No.

Ord. code

SITRANS P Compact pressure trans-

mitters for pressure and absolute

pressure with clamp-on remote seal

7 M F 8 0 1 0 -

2-wire system

Process temperature up to 140 °C

(284 °F)

Accuracy: 0.2% of full-scale value

Output 4 ... 20 mA

2

7 7 7 7

-

7 7 7 7 7 7 7

Housing design (stainless steel mat.

No. 1.4404/316L) / electr. connection

Housing with angled plug to DIN 43650,

IP65, union nut made of polyamide

1

Housing with round plug M12, IP65,

union nut made of polyamide

2

Housing with round plug M12, IP65,

union nut made of stainless steel

3

Stainless steel field housing (small) with

cable gland, IP65

4

Stainless steel field housing (small) with

cable gland, IP67

Internal ventilation for measuring ranges

< 10 bar (< 145 psi)

5

Measured range

Overload pressure

0 ... 160 mbar g

(0 ... 2.32 psi g)

2 bar g

(29 psi g)

B B

0 ... 250 mbar g

(0 ... 3.63 psi g)

2 bar g

(29 psi g)

B C

0 ... 400 mbar g

(0 ... 5.8 psi g)

6 bar g

(87 psi g)

B D

0 ... 600 mbar g

(0 ... 8.7 psi g)

6 bar g

(87 psi g)

B E

0 ... 1 bar g

(0 ... 14.5 psi g)

10 bar g

(145 psi g)

C A

0 ... 1.6 bar g

(0 ... 23.2 psi g)

10 bar g

(145 psi g)

C B

0 ... 2.5 bar g

(0 ... 36.3 psi g)

16 bar g

(232 psi g)

C C

0 ... 4 bar g

(0 ... 58 psi g)

16 bar g

(232 psi g)

C D

0 ... 6 bar g

(0 ... 87 psi g)

30 bar g

(435 psi g)

C E

0 ... 10 bar g

(0 ... 145 psi g)

30 bar g

(435 psi g)

D A

0 ... 16 bar g

(0 ... 232 psi g)

50 bar g

(725 psi g)

D B

0 ... 25 bar g

(0 ... 363 psi g)

50 bar g

(725 psi g)

D C

0 ... 40 bar g

(0 ... 580 psi g)

70 bar g

(1015 psi g)

D D

-160 ... 0 mbar g

(-2.32 ... 0 psi g)

2 bar g

(29 psi g)

E B

-250 ... 0 bar g

(-3.73 ... 0 psi g)

2 bar g

(29 psi g)

E C

-400 ... 0 bar g

(-5.8 ... 0 psi g)

6 bar g

(87 psi g)

E D

-600 ... 0 bar g

(-8.7 ... 0 psi g)

6 bar g

(87 psi g)

E E

-1 ... 0 bar g

(-14.5 ... 0 psi g)

10 bar g

(145 psi g)

F A

-1 ... 0.6 bar g

(-14.5 ... 8.7 psi g)

10 bar g

(145 psi g)

F B

-1 ... 1.5 bar g

(-14.5 ... 21.8 psi g)

16 bar g

(232 psi g)

F C

-1 ... 3 bar g

(-14.5 ... 43.5 psi g)

16 bar g

(232 psi g)

F D

-1 ... 5 bar g

(-14.5 ... 72.5 psi g)

30 bar g

(435 psi g)

F E

Selection and Ordering data

Order No.

Ord. code

SITRANS P Compact pressure trans-

mitters for pressure and absolute

pressure with clamp-on remote seal

7 M F 8 0 1 0 -

2-wire system

Process temperature up to 140 °C

(284 °F)

Accuracy: 0.2% of full-scale value

Output 4 ... 20 mA

2

7 7 7 7

-

7 7 7 7 7 7 7

Measured range

Overload pressure

(continued)

-1 ... 9 bar g

(-14.5 ... 130.5 psi g)

30 bar g

(435 psi g)

G A

-1 ... 15 bar g

(-14.5 ... 217.6 psi g)

50 bar g

(725 psi g)

G B

0 ... 1 bar a

(0 ... 14.5 psi a)

10 bar a

(145 psi a)

F)

H A

0 ... 1.6 bar a

(0 ... 23.2 psi a)

10 bar a

(145 psi a)

F)

H B

0 ... 2.5 bar a

(0 ... 36.3 psi a)

16 bar a

(232 psi a)

F)

H C

0 ... 4 bar a

(0 ... 58 psi a)

16 bar a

(232 psi a)

F)

H D

0 ... 6 bar a

(0 ... 87 psi a)

30 bar a

(435 psi a)

F)

H E

0 ... 10 bar a

(0 ... 145 psi a)

30 bar a

(435 psi a)

F)

J A

Special version

(add Order code and plain text)

F)

Z A

P 1 Y

Explosion protection

without

1

with, to ATEX 100a, II 2 G, EEx ib IIC T6

2

Further designs

Order code

Please add "-Z" to Order No. and specify

Order code

Hygiene version

P01

Roughness of process connection:

Foil R

a

< 0.8 μm (3.15·10

-8

inch);

Welded seams R

a

< 1.5 μm

(5.9·10

-8

inch)

Integral cooling element

K01

Process temperature max. 200 °C

(392 °F) instead of 140 °C (284 °F)

Connections for pipe

Pipes to DIN 11850

R01

ISO pipes to ISO 2463

R02

Pipes to O. D. Tubing "BS 4825 Part 1"

R03

Certificates

Quality inspection certificate (Factory

calibration) to IEC 60770-2

C11

Acceptance test certificate to

EN 10204-3.1

C12

Use of FDA-listed remote seal filling liq-

uids certified by factory certificate

to EN 10204-2.2

C17

Roughness depth measurement R

a

certified by factory certificate

to EN 10204-3.1

C18

Certification to EHEDG for clamp-on

seals with aseptic screwed gland

to DIN 11864

C19

© Siemens AG 2008