Sitrans p measuring instruments for pressure – Siemens SITRANS P User Manual

Page 104

SITRANS P measuring instruments for pressure

Transmitters for gage, absolute and differential pressure, flow and level

DS III series for absolute pressure

(from differential pressure series)

2/104

Siemens FI 01 · 2009

2

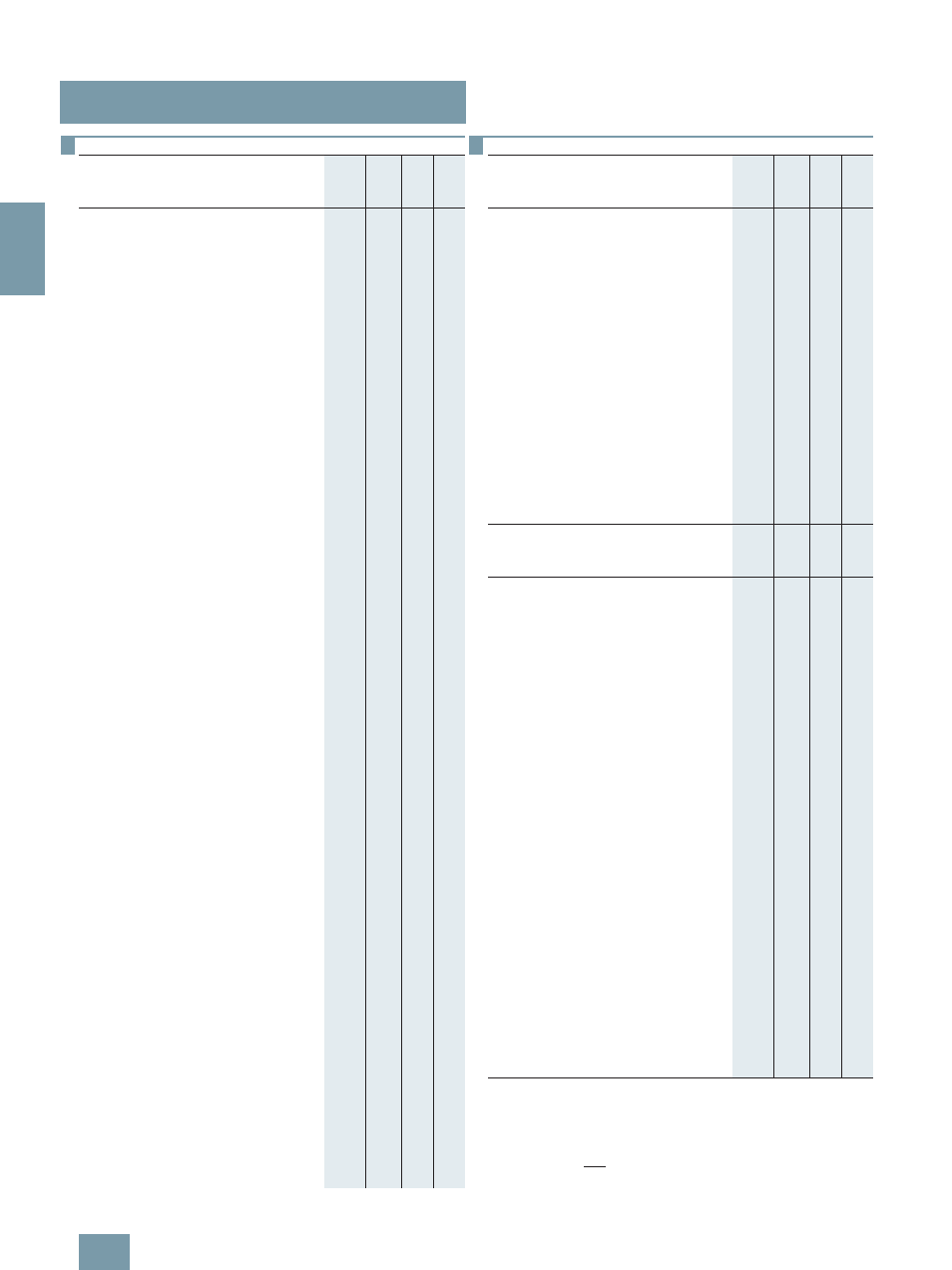

Selection and Ordering data

Order code

Further designs

HART PA

FF

Add "-Z" to Order No. and specify Order

code.

Pressure transmitter with mounting

bracket made of:

• Steel

A01

9

9

9

9

9

9

• Stainless steel

A02

9

9

9

9

9

9

O-rings for process flanges

(instead of FPM (Viton))

• PTFE (Teflon)

A20

9

9

9

9

9

9

• FEP (with silicone core, approved for food)

A21

9

9

9

9

9

9

• FFPM (Kalrez, compound 4079)

A22

9

9

9

9

9

9

• NBR (Buna N)

A23

9

9

9

9

9

9

Plug

• Han 7D (metal, gray)

A30

9

9

• Han 8U (instead of Han 7D)

A31

9

9

Sealing screws

A40

9

9

9

9

9

9

¼-18 NPT, with valve in material of process

flanges

Cable sockets for M12 connectors (metal)

A50

9

9

9

9

9

9

Rating plate inscription

(instead of German)

• English

B11

9

9

9

9

9

9

• French

B12

9

9

9

9

9

9

• Spanish

B13

9

9

9

9

9

9

• Italian

B14

9

9

9

9

9

9

English rating plate

B21

9

9

9

9

9

9

Pressure units in inH

2

O or psi

Quality inspection certificate (Factory cali-

bration) to IEC 60770-2

1)

C11

9

9

9

9

9

9

Acceptance test certificate

2)

C12

9

9

9

9

9

9

To EN 10204-3.1

Factory certificate

C14

9

9

9

9

9

9

To EN 10204-2.2

"Functional Safety (SIL)" certificate

C20

9

9

"PROFIsafe" certificate and protocol

C21

9

9

Setting of upper limit of output signal to

22.0 mA

D05

9

9

Manufacturer's declaration acc. to NACE

D07

9

9

9

9

9

9

(only together with seal diaphragm made of

Hastelloy and stainless steel)

Type of protection IP68

D12

9

9

9

9

9

9

(not together with Han 7D/Han 8U plug,

cable gland PG 13.5)

Digital indicator alongside the input keys

D27

9

9

9

9

9

9

(only together with the devices 7MF4333-

....2-.A.6 or -.A.7-Z, Y21 or Y22 + Y01)

Supplied with oval flange

D37

F)

9

9

9

9

9

9

(1 item), PTFE packing and stainless steel

screws in thread of process flange

Use in or on zone 1D/2D

E01

9

9

9

9

9

9

(only together with type of protection "Intrinsic

safety (EEx ia)")

Use on zone 0

E02

9

9

9

9

9

9

(only together with type of protection "Intrinsic

safety (EEx ia)")

Oxygen application

E10

9

9

9

9

9

9

(max. 120 bar a (1740 psi a) at 60°C (140 °F)

with oxygen measurement and inert liquid)

Explosion-proof "Intrinsic safety" to

INMETRO (Brazil)

E25

9

9

9

9

9

9

(only for transmitter 7MF4...-.....-.B..)

Explosion-proof "Intrinsic safety" to NEPSI

(China)

E55

9

9

9

9

9

9

(only for transmitter 7MF4...-.....-.B..)

Explosion protection "Explosion-proof" to

NEPSI (China)

E56

9

9

9

9

9

9

(only for transmitter 7MF4...-.....-.D..)

Explosion-proof "Zone 2" to NEPSI (China) E57

9

9

9

9

9

9

(only for transmitter 7MF4...-.....-.E..)

Interchanging of process connection side

H01

9

9

9

9

9

9

Vent on side for gas measurements

H02

9

9

9

9

9

9

Process flange

• Hastelloy

K01

9

9

9

9

9

9

• Monel

K02

9

9

9

9

9

9

• Stainless steel with PVDF insert

max. PN 10 (MWP 145 psi),

max. temperature of medium 90 °C (194 °F)

K04

9

9

9

9

9

9

For ½-14 NPT inner process connection on

the side in the middle of the process flange,

vent valve not possible

Additional data

Add "-Z" to Order No. and specify Order

code.

Measuring range to be set

Y01

9

9

Specify in plain text (max. 5 digits):

Y01: ... up to ... mbar, bar, kPa, MPa, psi

Measuring point number (TAG No.)

Y15

9

9

9

9

9

9

Max. 16 characters, specify in plain text:

Y15: ...........................................

Measuring point text

Y16

9

9

9

9

9

9

Max. 27 characters, specify in plain text:

Y16: ...........................................

Entry of HART address (TAG)

Y17

9

9

Max. 8 characters, specify in plain text:

Y17: ...........................................

Setting of pressure indication in pressure

units

Y21

9

9

9

9

9

9

Specify in plain text (standard setting: mA):

Y21: mbar, bar, kPa, MPa, psi, ...

Note:

The following pressure units can be selected:

bar, mbar, mm H

2

O

*)

, inH

2

O

*)

, ftH

2

O

*)

,

mmHG, inHG, psi, Pa, kPa, MPa, g/cm

2

,

kg/cm

2

, Torr, ATM oder %

*) ref. temperature 20 °C

Setting of pressure indication in

non-pressure units

Y22 +

Y01

9

9

Specify in plain text:

Y22: ..... up to ..... l/min, m

3

/h, m, USgpm, ...

(specification of measuring range in pressure

units "Y01" is essential, unit with

max. 5 characters)

Preset bus address

Y25

9

9

(possible between 1 and 126)

Specify in plain text:

Y25: .....................

Only "Y01", "Y21", "Y22", "Y25" and "D05" can be factory preset

9

9 = available

1)

When the manufacture’s certificate M (calibration certificate) has to be

ordered for transmitters with diaphragm seals, it is recommended only to

order this certificate exclusively with the diaphragm seals. The measuring

accuracy of the total combination is certified here.

2)

Whe the acceptance test certificate 3.1 for transmitters with direct-con-

nected diaphragm seals is ordered, this certificate must also be ordered

with the corresponding seals.

Selection and Ordering data

Order code

Further designs

HART PA

FF

Add "-Z" to Order No. and specify Order

code.

F) Subject to export regulations AL: 9I999, ECCN: N.

© Siemens AG 2008