Compensation vessels, Sitrans p measuring instruments for pressure, Fittings - accessories – Siemens SITRANS P User Manual

Page 232: Compensation vessels 2/232

SITRANS P measuring instruments for pressure

Fittings - Accessories

Compensation vessels

2/232

Siemens FI 01 · 2009

2

■

Overview

The compensation vessels prevent the level difference which oc-

curs with pressure changes in the pressure lines and which fal-

sifies the measurement.

According to DIN 19211, the temperature in the compensation

vessel must be assumed to be 50 K less than the steam temper-

ature in the pipe when calculating the wall thicknesses. This is

because the temperature in the compensation vessel during op-

eration can only rise up to the saturated steam temperature.

A material acceptance test certificate A to EN 10204-3.1 is avail-

able for the materials from which the compensation vessels are

made.

■

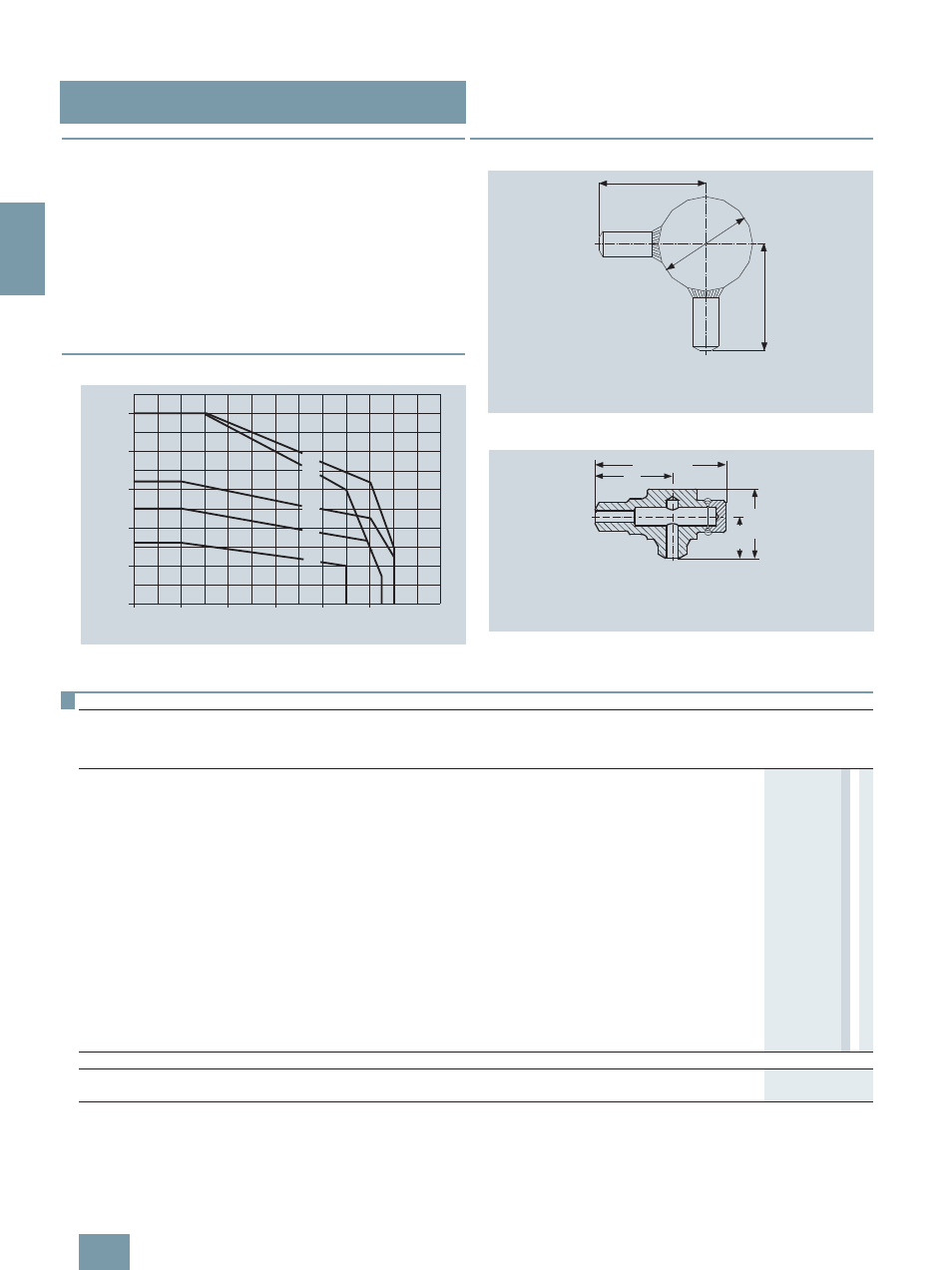

Characteristic curves

Permissible operating pressure as a function of the permissible operating

temperature

■

Dimensional drawings

Compensation vessel 7MF9015-1.., dimensions in mm

Compensation vessel 7MF9015-5.., dimensions in mm

0

100

200

300

400

bar

°C

0

100

200

300

400

500

500

600

E

D

C

B

A

Op

era

tin

g p

re

ss

ure

Operating temperature

100

88,9

100

I

O

O Output (see Ordering data for dimensions)

I

Input (see Ordering data for dimensions)

65

35

1

)

58

1

)

I

O

approx. 110

I

Input (see Ordering data for dimensions)

O Output (see Ordering data for dimensions)

1

) 30 mm longer with 7MF9015-5A.

Selection and Ordering data

Compensation vessel, without certificate

Max.

working

pressure

Characteristic

1)

Material

Mat. No. Connections

Approx.

contents

cm³

Approx.

weight

kg

Order No.

Input

Output

7 M F 9 0 1 5 -

7 7

A

160 bar

A

16 Mo 3

1.5415

Threaded socket G½,

form R, DIN 19207

Threaded socket G½,

form V, DIN 19207

250

0.8

1 A

250 bar

B

16 Mo 3

1.5415

Welding sleeve

∅ 21 mm × 6.3 mm

Welding sleeve

∅ 21.3 mm × 6.3 mm

250

0.8

1 B

250 bar

B

16 Mo 3

1.5415

Welding sleeve

∅ 24 mm × 7.1 mm

Welding sleeve

∅ 24 mm × 7.1 mm

250

1

1 C

250 bar

C

11 CrMo 9 10

1.7383

Welding sleeve

∅ 24 mm × 7.1 mm

Welding sleeve

∅ 24 mm × 7.1 mm

250

1

1 D

250 bar

B

16 Mo 3

1.5415

Welding sleeve

∅ 33.7 mm × 4.5 mm

Welding sleeve

∅ 24 mm × 7.1 mm

250

0.7

1 E

160 bar

A

16 Mo 3

1.5415

Threaded socket G½,

form R, DIN 19207

Threaded socket G½,

form V, DIN 19207

20

1.6

5 A

500 bar

D

16 Mo 3

1.5415

Welding sleeve

∅ 21 mm × 6.3 mm

Welding sleeve

∅ 21.3 mm × 6.3 mm

20

1.6

5 B

500 bar

D

16 Mo 3

1.5415

Welding sleeve

∅ 24 mm × 7.1 mm

Welding sleeve

∅ 24 mm × 7.1 mm

20

1.6

5 C

500 bar

E

11 CrMo 9 10

1.7383

Welding sleeve

∅ 24 mm × 7.1 mm

Welding sleeve

∅ 24 mm × 7.1 mm

20

1.6

5 D

Accessories

Factory test certificate EN 10204–2.2

7MF9000-8AB

Material acceptance test certificate EN 10204-3.1

7MF9000-8AD

1)

See Figure "Permissible working pressure as a function of the permissible working temperature"

© Siemens AG 2008