Reznor RXH (Outdoor PreevA) Unit Installation Manual User Manual

Page 59

Form I-RDH/REH/RHH/RXH (12-14), P/N 215210 R14, Page 59

.436 (centerline of ignitor to top of ribbon)

8.4.3 Ignitor Location

Proper location of the ignitor to the burner is shown in

FIGURE 55A. Ignitor spark gap

is shown in

FIGURE 55B. The ignitor is the same for all gas control options.

1/8 inch

(3.2mm)

FIGURE 55A - Ignitor Location

FIGURE 55B - Ignitor Spark Gap

LED 3-Character Display (displayed on power up)

Display Info (example only) Description

RDH

Furnace series or model name

400

Heat Section Size

nAt or LP

Fuel type

1.01

Software version

NOTE: Operating and

Lockout Error Codes

displayed on the ignition

controller 3-character

display (

FIGURE 53) are

listed in Troubleshooting

Paragraph in the

Operation/Maintenance/

Service Manual, Form

O-PREEVA.

FIGURE 54 - Spark Ignition

Board, P/N 257975, is located

on the removable shield at the

end of the burner.

CAUTION: Due to high voltage on the spark wire and electrode,

do not touch when energized. See Hazard Levels, page 2.

8.4.2 Ignition Control

Module used in Deep

Modulation Control

Options AG58 and

D12G

Integrated Control Module for Gas Control Options AG58 and D12G -

The con-

trol module is located in the control compartment with an additional board to

control spark that is attached to the removable shield on the end of the burner.

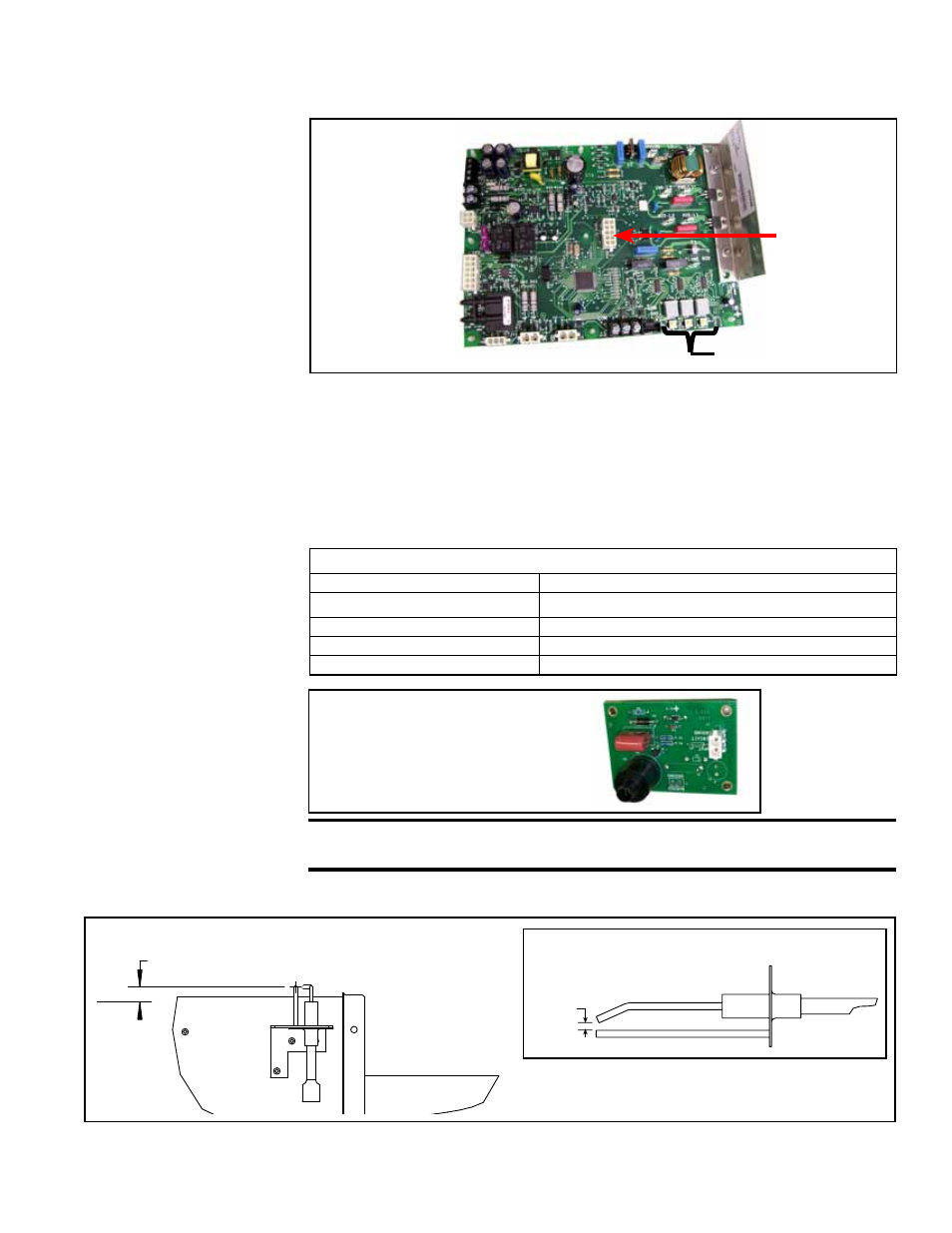

FIGURE 53 -

Integrated

Control Module

(Circuit Board),

for Deep

Modulation

Options AG58

and D12G

3-Character Display

ID Plug

(unique by

model, size,

and type of

gas)

IMPORTANT: The control

module is

P/N 260252 for

all sizes of Model RDH

and

P/N 260917 for all

sizes of RHH heat sec-

tions. However, the ID plug

on each board is unique for

each model, size, and type

of gas. A replacement board

will require either a new

ID plug or reuse of the ID

plug from the board being

replaced.

Except for the replaceable parts shown, do not attempt to disassemble either

board. Each heating season check the lead wires for insulation deterioration

and good connections.

If replacement is required, these boards must be replaced with identical parts.

The control has a built-in, self-diagnostic capability. The control continuously monitors

its own operation and the operation of the heat section including direct spark ignition,

safety and modulating valves, and venter motor speed. The 3-digit display on the con-

trol indicates the current system state, warnings, failures, and test modes.