0 mechanical (cont’d) – Reznor RXH (Outdoor PreevA) Unit Installation Manual User Manual

Page 40

Form I-RDH/REH/RHH/RXH (12-14), Page 40

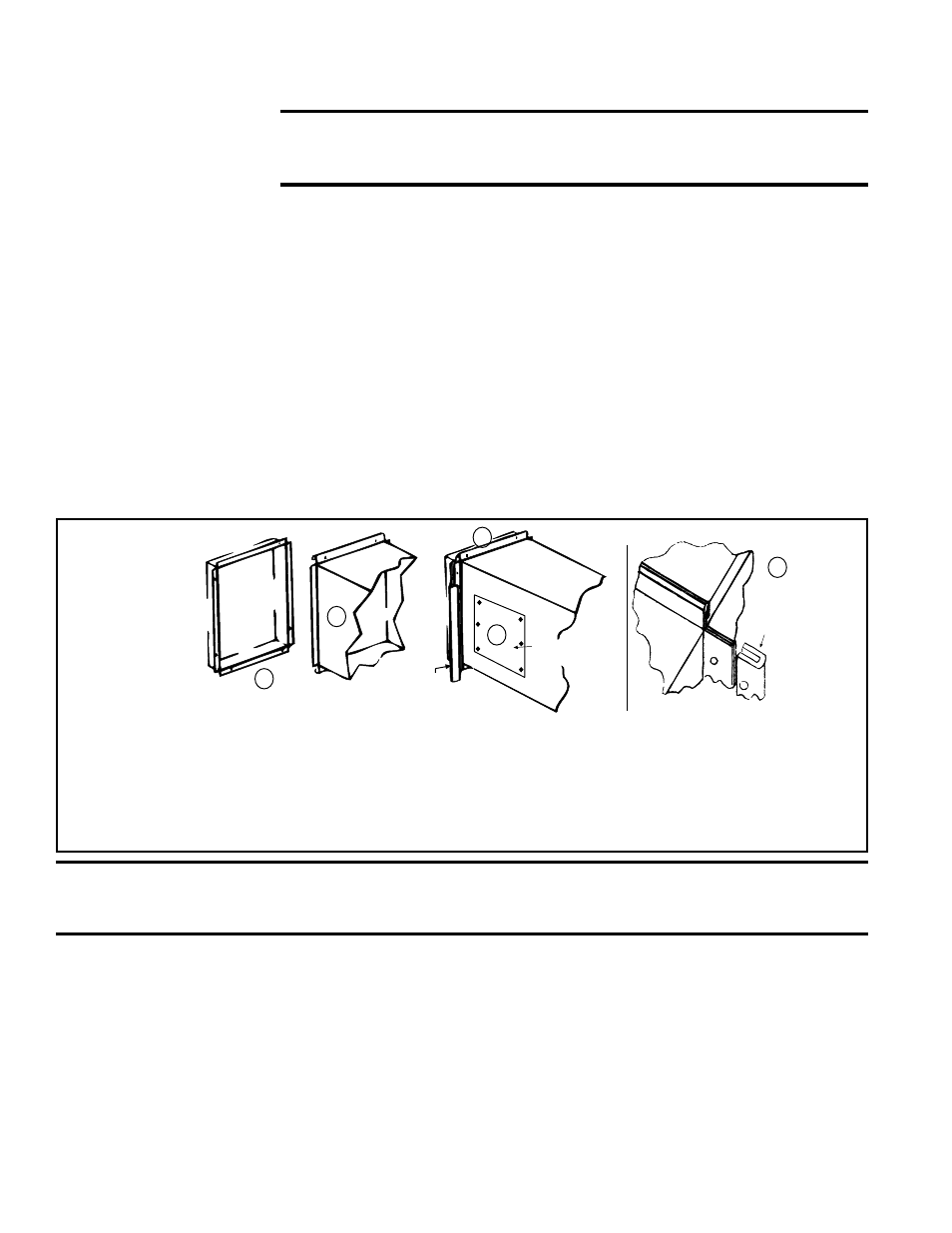

FIGURE 37 -

Connecting

Discharge

Ductwork

(1) If the heater has an optional duct flange, the flanges turn out as shown. (2) Shape duct connection as shown

with “U” on top and bottom and “L” on sides.

(3) Provide for sealed access panel in the ductwork. This opening must

be accessible when the furnace is in service and should be large enough to view smoke or reflected light, to detect

the presence of leaks in the heating equipment, and to check for hot spots on the heat exchanger due to poor air

distribution or lack of sufficient air (cfm). The cover for the opening must be attached in such a manner as to prevent

leakage.

(4) Slide “U” channels over top and bottom flanges on the heater. (5) Form field-supplied “U” channels over

side connections to seal. Drill and lock with sheetmetal screws.

Heater

Duct

Access Panel

in Duct

1

2

3

4

U Channel

(see englared

view on the right)

Furnace

Duct

U Channel

of Light

Gauge Metal

5

CAUTION: Joint where supply air duct attaches to the furnace must be sealed securely to

prevent air leakage. Leakage can cause poor combustion, shorten heat exchanger life, and

cause poor performance. See Hazard levels, page 2.

All gas or electric control options for makeup air (except AG40) include a discharge

air sensor that requires field installation in the discharge duct. (Sensor is field-supplied

with Option AG 40.)

Options AG3, AG15, AG16, AG58, AG60, AG61 and AG62 are analog controls. Options

AG3 and AG60 have a unit mounted ductstat with a capillary sensor that will fit in the

holder in

FIGURE 38. Options AG16, AG58, AG60, AG61 and AG62 include sensors

that require duct mounting using the holder in

FIGURE 38 and field wiring. Follow the

instructions below to attach the holder and the sensor.

Sensors in Options DG5, DG6, D12B, D12C, D12D, D12E, and D12G are digital and

require duct mounting using the holder in

FIGURE 38 and field wiring. Digital control

inputs are low-current, resistance-based signals. For optimum temperature control

performance the analog and digital inputs (zone sensors, discharge air sensors, etc.)

6.8.5 Discharge Air

Sensor for Makeup Air

Application

6.0 Mechanical

(cont’d)

6.8.4 Requirements

and Recommendations

for Connecting and

Installing Ductwork

(cont’d)

Conditioning Contractors Association (www.acca.org), 2800 Shirlington Road, Suite

300, Arlington, VA 22206. A manual covering duct sizing in detail may be purchased

directly from them.

CAUTION: An external duct system static pressure not within the

limits shown on the rating plate, or improper motor pulley or belt

adjustment, may overload the motor. See Hazard Levels, page 2.

• Removable Panel (See FIGURE 37.) - The ductwork should have a removable

access panel. This opening must be accessible when the furnace is in service and

should be large enough to view smoke or reflected light, to detect the presence of

leaks in the heating equipment, and to check for hot spots on the heat exchanger

due to poor air distribution or lack of sufficient air (cfm). The cover for the opening

must be attached in such a manner as to prevent leakage.

• Horizontal Discharge Duct Length - A minimum horizontal duct run of 24”

(610mm) is recommended before turns or branches are made in the duct system

to reduce losses at the furnace outlet.

• Discharge Air Horizontal Connection (See FIGURE 37.) - The seal between the

heater and the duct must be mechanical. Duct connection should be made with

“U” type flanges on the top and bottom of the connecting duct. Slide the duct over

the flanges of the heater giving an airtight fit. Provide “U” type channels for the

side flanges to ensure tight joints. Fasten “U” channels with sheetmetal screws.

• Bottom Duct Connection - To minimize sound and vibration transmission, use

a flexible duct connection. Duct must be attached and sealed to provide air tight

connection.

6.8 Unit Discharge -

RDH, REH, RHH,

and RXH