0 mechanical (cont’d), Instructions for high altitude derate – Reznor RXH (Outdoor PreevA) Unit Installation Manual User Manual

Page 20

Form I-RDH/REH/RHH/RXH (12-14), Page 20

Derate by Valve Outlet

Pressure Adjustment

if needed for High

Altitude Operation

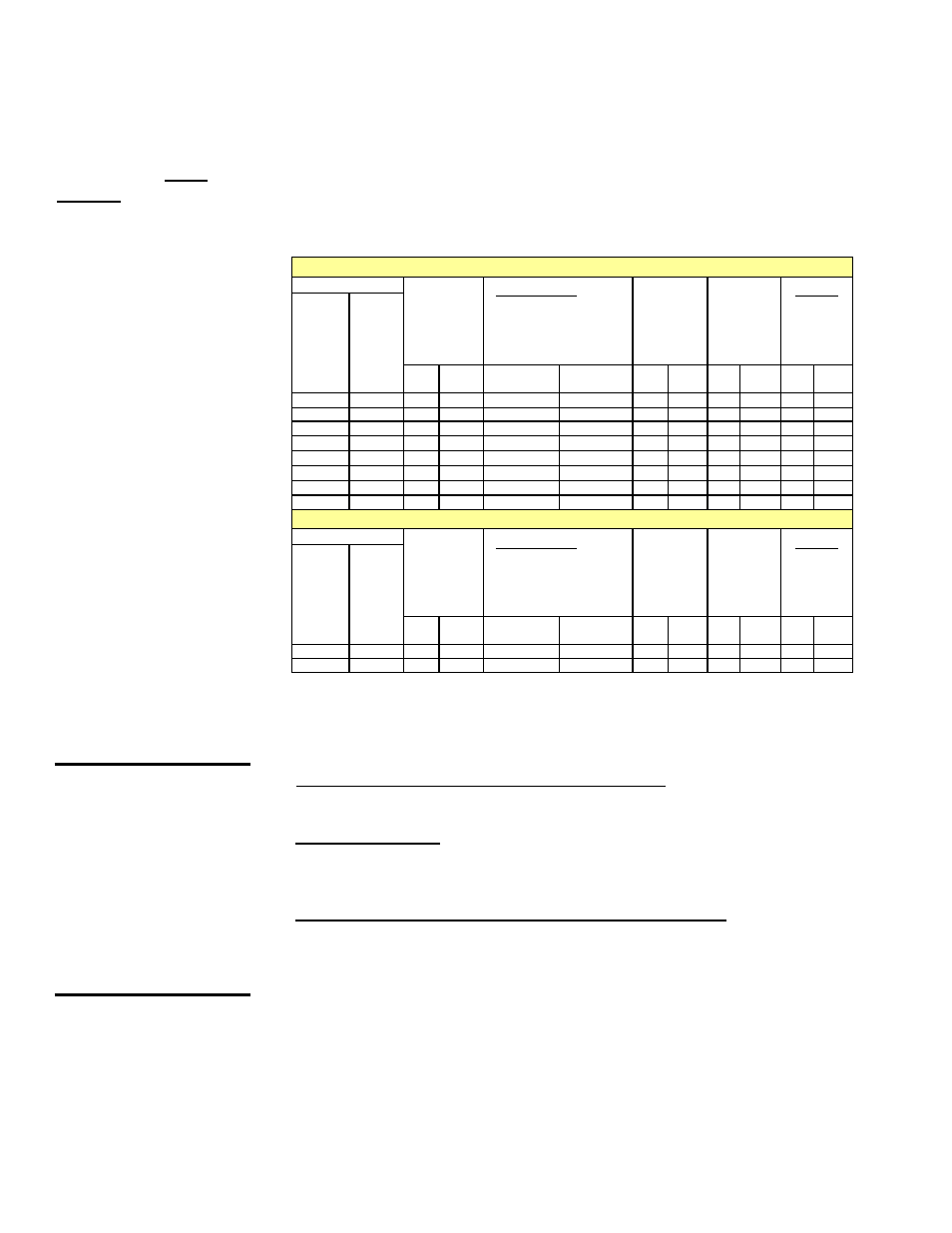

TABLE 11 - Valve Outlet

Pressure Settings by

Elevation, Gas Control

Option, and Type of

Gas for Models RDH

and RHH

If the elevation on the rating plate does not match the elevation of the installation site,

follow these instructions to adjust the valve.

Instructions for High Altitude Derate

1. Refer to TABLE 11 and determine the required valve outlet pressure(s) for the

elevation where the heater will be operating. If unsure of the elevation, contact the

local gas supplier. If unsure of the type of gas control, check the option list on the

unit wiring diagram.

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result in

unregulated manifold

pressure causing

excess overfire and

heat exchanger

failure.

2. Locate the 1/8” outlet pressure tap on the valve (FIGURE 11A, page 17). Turn the

or switch knob on the top of the valve to “OFF”. Connect a manometer to the 1/8”

outlet pressure tap in the valve. Use a water column manometer that is readable

to the nearest tenth of an inch. When making the adjustment, turn the adjustment

screw IN (clockwise) to increase pressure or OUT (counterclockwise) to decrease.

3. Single-Stage and Two-Stage High Fire Adjustment - Turn the switch or knob on

the top of the valve to “ON”. Remove the cap from the pressure adjusting screw

and adjust the outlet pressure to the full rate pressure selected from

TABLE 11.

Two Stage Low Fire - Disconnect the wire from the “HI” terminal on the gas valve

and check low fire pressure. To adjust, turn the low pressure regulator screw to

achieve the “2-Stage Low Fire” pressure listed

for the applicable gas control

(TABLE 11). Re-connect the wire to the gas valve.

Electronic Modulation Options AG40, DG2, DG6, and D12B - The electronic

modulation valve itself has no high fire adjustment. The only adjustment on the

modulation valve is the low-pressure bypass setting which is factory set and does

not require field adjustment for high altitude operation.

However, if the elevation on the rating plate does not match the elevation of the

installation, a full rate adjustment is required at the outlet of the combination valve.

To make the full rate adjustment, adjust the outlet pressure of the combination gas

valve when the modulating valve is fully open (there must be a minimum of a 20

VDC signal at the electronic modulating valve to ensure that it is fully open). Set

the outlet pressure of the combination valve to the pressure shown in

TABLE 11.

4. Turn up the thermostat. Cycle the burner once or twice to properly seat the

adjustment spring in the valve. Re-check the pressure(s). When the outlet

pressure(s) is right for the installation, remove the manometer and replace the

cap. Check for a leak at the pressure tap fitting.

6.0 Mechanical

(cont’d)

6.1 Gas Piping and Pressures - Models RDH and RHH (cont’d)

6.1.3 High Altitude Operation - Gas-Fired Model RDH or RHH being

installed above 2000 ft (610M) (cont’d)

Outlet Pressure Settings (inches w.c.) by Altitude for Installation in the UNITED STATES

Altitude

Full Rate Outlet

Pressure (Single-

Stage & 2-Stage

High Fire) - Applies

to Options AG1,

AG2, AG3, AG15,

AG16, AG60, AG61,

AG62, DG1, DG5,

D12C, D12F

Full Rate Outlet Pressure with

Electronic Modulation - Applies to

Options AG8, AG9, AG9H, AG40, DG2,

DG6, and D12B (measured at the outlet

pressure tap just behind the orifice

adapter when there is a minimum

of a 20VDC signal at the electronic

modulating valve)

NOTE: Options do not apply to SHH.

2-Stage Low-Fire

Outlet Pressure -

Applies to Options

AG2, AG3, AG15,

and AG16

2-Stage Low-Fire

Outlet Pressure

with Venter

Motor Controller

- Applies to

Options AG60,

AG61, AG62, DG1,

DG5, D12C

Factory-Set

Bypass Pressure

with Electronic

Modulation

- Applies to

Options AG40,

DG2, DG6, D12B

FEET

METERS

Natural

Gas

Propane

Natural

Gas

Propane

Natural

Gas

Propane Natural

Gas

Propane Natural

Gas

Propane

0 - 2000

0 - 610

3.5

10.0

3.5

10.0

1.8

5.0

0.40

1.8

0.25

1.8

2001 - 3000

611 - 915

3.1

8.8

3.1

8.8

1.6

4.4

0.35

1.5

0.25

1.8

3001 - 4000

916 - 1220

3.0

8.5

3.0

8.5

1.5

4.2

0.34

1.4

0.25

1.8

4001 - 5000

1221 - 1525

2.8

8.1

2.8

8.1

1.5

4.1

0.32

1.4

0.25

1.8

5001 - 6000

1526 - 1830

2.7

7.7

2.7

7.7

1.4

3.9

0.31

1.3

0.25

1.8

6001 - 7000

1831 - 2135

2.6

7.4

2.6

7.4

1.3

3.7

0.30

1.3

0.25

1.8

7001 - 8000

2136 - 2440

2.5

7.1

2.5

7.1

1.3

3.5

0.28

1.2

0.25

1.8

8001 - 9000

2441 - 2745

2.4

6.7

2.4

6.7

1.2

3.4

0.27

1.1

0.25

1.8

Outlet Pressure Settings (inches w.c.) by Altitude for Installation in CANADA

Altitude

Full Rate Outlet

Pressure (Single-

Stage & 2-Stage

High Fire) - Applies

to Options AG1,

AG2, AG3, AG15,

AG16, AG60, AG61,

AG62, DG1, DG5,

D12C, D12F

Full Rate Outlet Pressure with

Electronic Modulation - Applies to

Options AG8, AG9, AG9H, AG40, DG2,

DG6, and D12B (measured at the outlet

pressure tap just behind the orifice

adapter when there is a minimum

of a 20VDC signal at the electronic

modulating valve)

NOTE: Options do not apply to SHH.

2-Stage Low-Fire

Outlet Pressure -

Applies to Options

AG2, AG3, AG15,

and AG16

2-Stage Low-Fire

Outlet Pressure

with Venter

Motor Controller

- Applies to

Options AG60,

AG61, AG62, DG1,

DG5, D12C

Factory-Set

Bypass Pressure

with Electronic

Modulation

- Applies to

Options AG40,

DG2, DG6, D12B

FEET

METERS

Natural

Gas

Propane

Natural

Gas

Propane

Natural

Gas

Propane Natural

Gas

Propane Natural

Gas

Propane

0 - 2000

0 - 610

3.5

10.0

3.5

10.0

1.8

5.0

0.4

1.8

0.25

1.8

2001 - 4500

611 - 1373

2.8

8.1

2.8

8.1

1.5

4.1

0.3

1.4

0.25

1.8