6 optional cooling coil module (factory installed), Danger (applies to optional reheat circuit) – Reznor RXH (Outdoor PreevA) Unit Installation Manual User Manual

Page 35

Form I-RDH/REH/RHH/RXH (12-14), P/N 215210 R14, Page 35

6.6.1 Cooling Coil Module General

The draw-through cooling coil module is factory assembled to the entering air side of

the system blower cabinet. Depending on which options were ordered, it will house

either a single, dual, or 1/3-2/3 circuit DX cooling coil or a chilled water coil with 1/4,

1/2, 3/4, or full circuiting. A DX coil will accommodate the refrigerant specified on the

order, either R410A, R134a, or R407c. Verify that the correct refrigerant was speci-

fied. If the coil was ordered for the incorrect refrigerant, contact your distributor or the

factory for revised capacity ratings and appropriate distributor nozzle(s). Distributor

nozzles may be changed in the field by a qualified technician.

If a cooling module was ordered with an optional reheat section (Option AU7L or

AU7R), the reheat circuit is factory charged with R410A refrigerant.

The split air-conditioning system requires a field-supplied condensing coil. Follow the instructions provided by the

condensing coil manufacturer to make the piping connections. If equipped with a multi-circuit coil, before making con-

nections, blow dry nitrogen into the circuit to determine which distributor goes with which suction line. (See connection

dimensions in

FIGURE 31 for chilled water or FIGURE 32A or 32B for DX coil

NOTE: If ordered with a Reznor

®

Model MASA condensing unit, follow the instructions in Form I-COND (shipped with

the condensing unit) for connecting the split system.

The coil module drain trough has an exterior 1” NPT connection. Connect the drain into a sanitary drain system. The

condensate trough and drain requires periodic cleaning.

Cooling control depends on which system control was ordered. If digital heating/cooling controls were ordered, see

Paragraph 8.3 and the control instruction form for information. If the cooling module was ordered with optional reheat

(Option AU7L or AU7R), the reheat circuit is factory charged with R410A refrigerant.

Condensing related controls such as thermal expansion valves and hot gas bypass may have been ordered with the unit

(R410-A only) or may be supplied locally.

6.6 Optional Cooling

Coil Module

(factory installed)

DANGER (Applies to Optional Reheat Circuit)

The reheat circuit contains R410A high pressure refrigerant. Hazards exist that could

result in personal injury or death. Installation, maintenance, and service should only be

performed by an HVAC technician qualified in R410A refrigerant and using proper tools and

equipment. DO NOT USE service equipment or tools designed for R22 refrigerant.

IMPORTANT: Do not release refrigerant to the atmosphere! If required service procedures

include the adding or removing of refrigerant, the service technician must comply with

all federal, state and local laws. The procedures discussed in this manual should only be

performed by a qualified HVAC technician.

1 MPT

Drain

1-1/2

MPT

with 1/4 NPT

Vent

A

with 1/4

NPT

Drain

7-27/32

(199mm)

10-9/64

(258mm)

16-13/16

(427mm)

19-31/32 (507mm)

3-3/32 (79mm)

Inlet Air View

(factory attached to

optional mixing

box or evaporative

cooling module or

location for field-

installed hood)

This

end is

attached

to the

blower

cabinet

at the

factory.

Side

View

Airflow

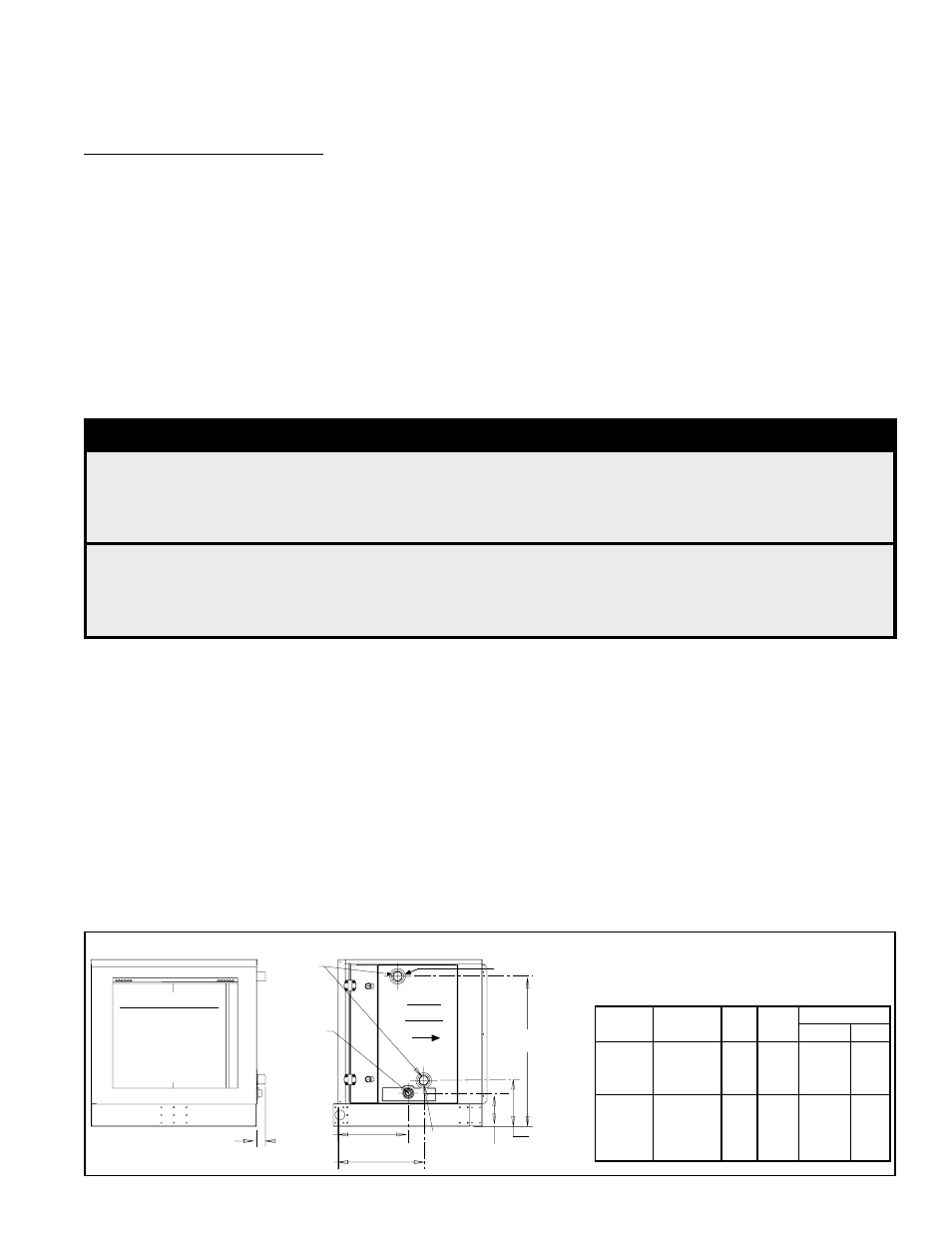

FIGURE 31 - Dimensions of Chilled Water Cooling Coil Module, Option AU6

TABLE 22 - Chilled Water Cooling

Coil Module Dimensions

RDH

Size

REH

Size

RHH

Size

RXH

Size

A

inches

mm

75/100/

125/150

10A/20A/

40A/15B/

30B/60B

N/A 000A/

000B 33-1/4

844

175/200/

225/250/

300/350/

400A

30D/60D/

90D/120D/

40E/80E/

120E

130/

180/

260/

350

000C/

000D/

000E

43-7/32 1199

6.6.2 Cooling Coil Module Dimensions

is restored. Check the “ON” timing; the media pads should be wet from top to bottom

during the ON cycle.

If the preset timing is not suitable for the application, follow the instructions supplied

with the microprocessor to change the calibration of the “ON” and/or “OFF” cycle.

All Evaporative Cooing Modules - Check the reservoir for any water leaks. If any small leaks are present, drain the

reservoir. Dry and apply a waterproof silicone sealer around corners and welds.