Reznor RXH (Outdoor PreevA) Unit Installation Manual User Manual

Page 19

Form I-RDH/REH/RHH/RXH (12-14), P/N 215210 R14, Page 19

Top View

Side

View

Ball Valve

Actuator

Ball Valve

Actuator

Combination

Single-Stage

Gas Valve

Pressure

Tranducer

Ball Valve

Gas Valve

Bracket

Orifice

Manifold

Pressure

Tap

FIGURE 12 - Gas

Manifold with Gas

Control Options AG58

and D12G

6.1.3 High Altitude

Operation - Gas-Fired

Model RDH or RHH

being installed above

2000 ft (610M)

Adjustments for High

Altitude Operation

(does not apply to Models

RDH and RHH with

Option AG58 or D12G)

After an adjustment is made, cycle the heat section. Re-check the outlet pressure of

the valve and the manifold pressure. When pressure is correct for highest fire, remove

the manometers and replace the caps. Check for a leak at the pressure tap fittings.

3) Lowest fire manifold pressure is regulated by the ball valve actuator in response to

signals from the ignition control board. The ball valve was set at the factory and should

not need to be checked at startup. For future reference, instructions for checking low-

est fire pressure are in Form O-PREEVA included in the literature bag.

NOTE: Altitude adjustment does NOT apply to Model RDH or RHH with Gas Con-

trol Option AG58 or D12G -- Modulating gas control Options AG58 and D12G DO

NOT require a gas pressure adjustment derate for high altitude. The patented

control system works on a principle of safe, continuous gas and combustion air moni-

toring and adjustment. As the mass flow through the combustion system changes, due

to the lower oxygen level at high altitude, the control system senses the change, auto-

matically reducing the firing rate of the burner.

If the heater is being installed at an elevation above 2000 ft (610M), check the rat-

ing plate to verify that the heater is factory-equipped for the elevation at the installation

site.

If the elevation on the rating plate matches the elevation of the installation

site, field adjustment for high altitude is not required.

If the rating plate does not match the elevation of the installation site, high altitude

adjustment will need to be done as part of the startup procedure. (High altitude adjust-

ment can only be done while the unit is operating.) During startup, follow the instruc-

tions in this section to adjust the valve outlet pressure.

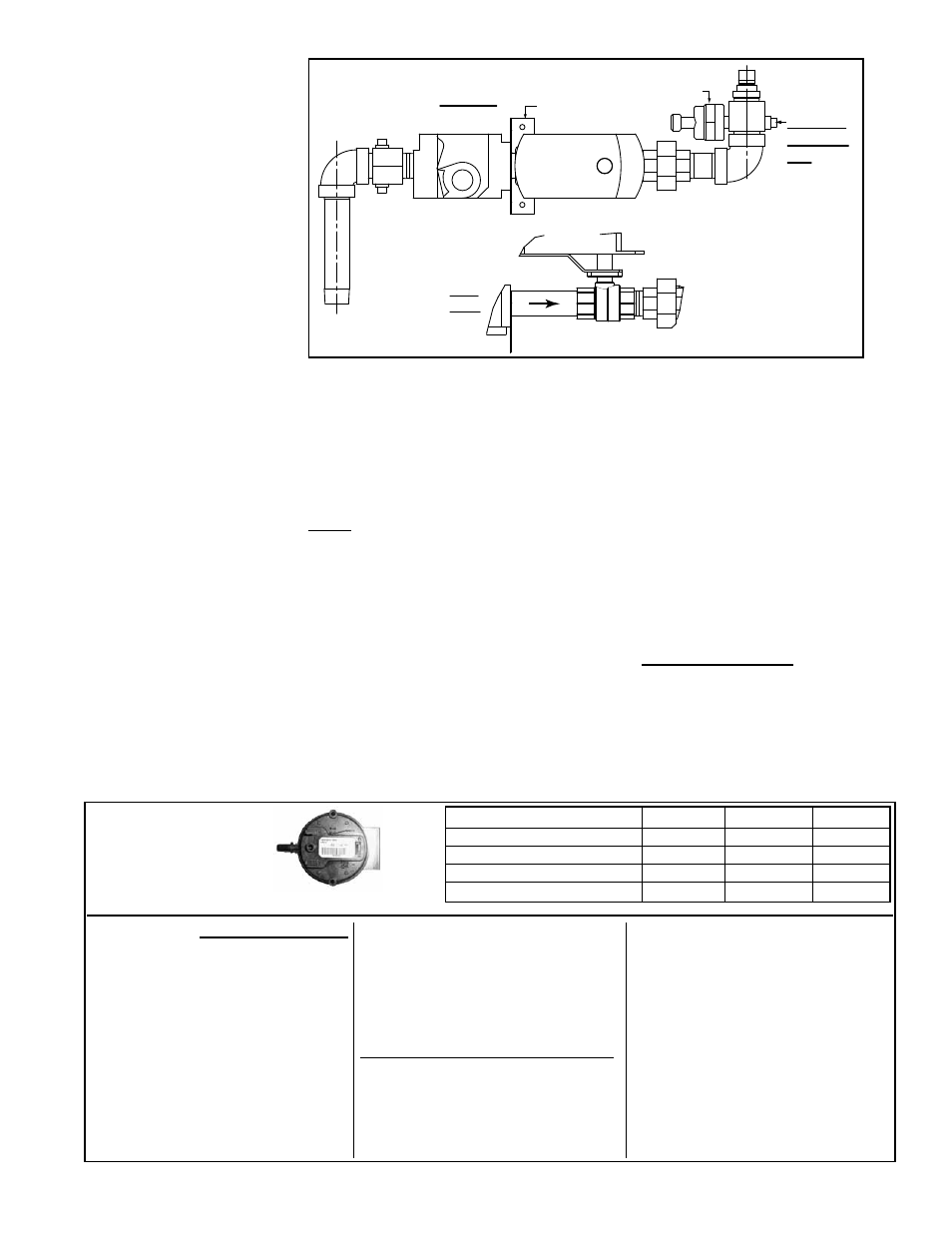

FIGURE 13 -

High Altitude

(>6000ft/1830M)

Pressure Switch

Requirement

Pressure Switch

NOTE: If unit is above 6000 ft (1830M)

elevation and the following conditions

apply, installation of a high altitude pres-

sure switch is required. If a replacement

switch is needed, contact your distributor

for the switch and follow the instructions

below to install the high altitude pressure

switch before starting the heater.

□

Elevation on the rating plate is not

above 6000 ft (1830M)

□

Unit has a single or two-stage gas

control (Option AG1, AG2, AG3, AG15,

AG16, AG60, DG1, DG5, or D12C).

NOTE: If equipped with a two-stage

control with a two-speed venter

(Options AG8, AG9, AG9H, AG60,

AG61, AG62, DG1, DG5, and D12C),

there are two pressure switches. Only

the high speed pressure switch needs

to be changed.

Instructions for changing pressure switch:

1. If the unit is installed, turn off the gas

and the power.

2. In the control compartment, locate

the pressure switch that needs to be

replaced. (

NOTE: If there are two

pressure switches, the high speed

switch to be replaced is toward the top

of the unit.)

3. Mark and disconnect the two wires

attached to the pressure switch.

4. Mark and disconnect the sensing

tube(s) from the pressure switch.

5. Locate the two screws holding the

switch mounting bracket. Remove the

pressure switch. Save the screws.

6. Using the same screws, install the

high altitude pressure switch. Attach

sensing tube(s) and wires.

7. If installed, turn on the power and the

gas.

Above 6000 ft (1830M)

Switch P/N Label Color Setting

RDH 75, 100

197031

Purple

0.35” w.c.

RDH 125

197032

Pink

0.45” w.c.

RDH 150

197029

Lt Blue

0.60” w.c.

RDH 175-400 & RHH all Sizes

201160

Brown

1.05” w.c.