0 mechanical (cont’d) – Reznor RXH (Outdoor PreevA) Unit Installation Manual User Manual

Page 18

Form I-RDH/REH/RHH/RXH (12-14), Page 18

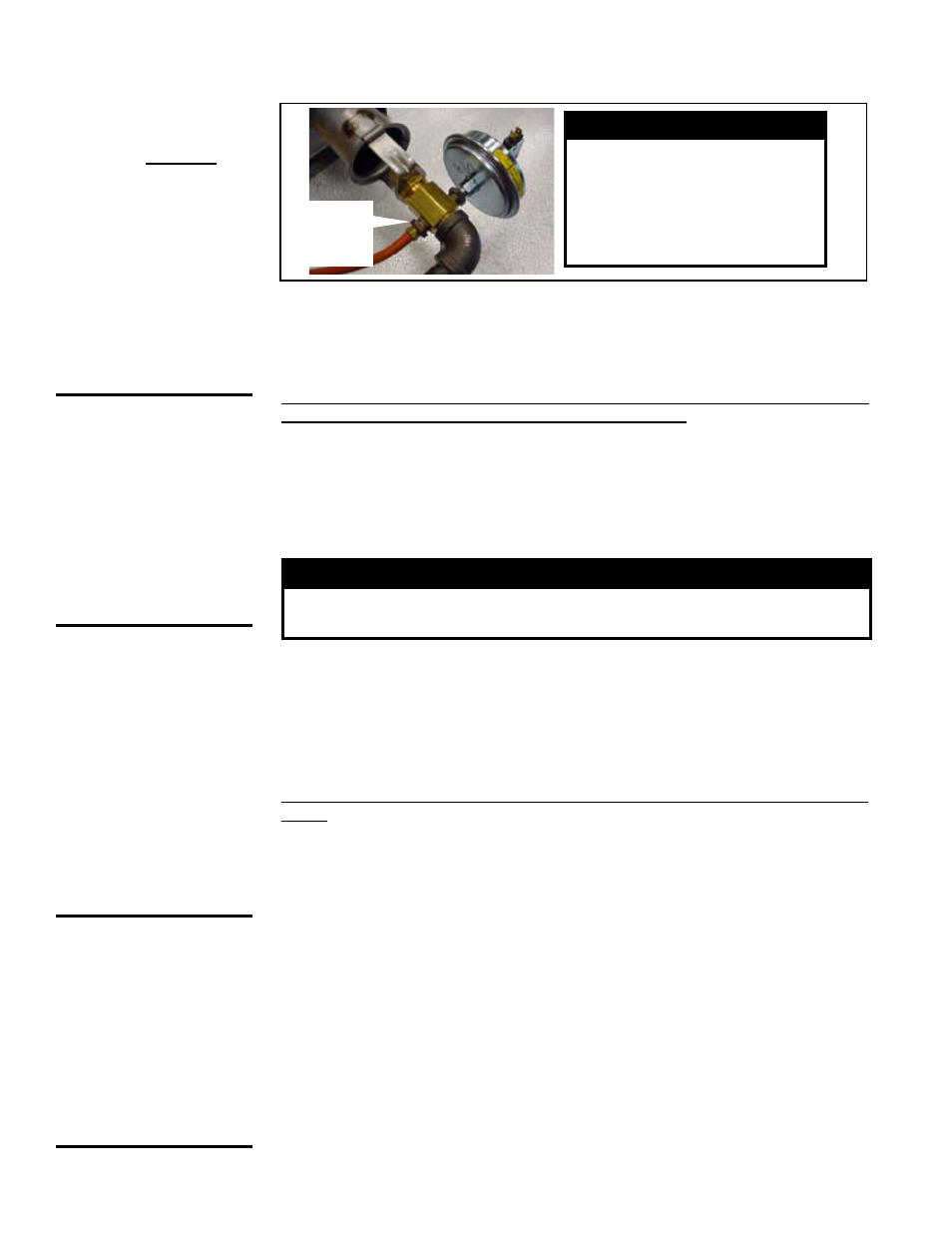

FIGURE 11C - Pressure

Tap Location for

Measuring Low Fire

Outlet (Bypass)

Pressure -- Electronic

Modulation Gas Control

Options AG8, AG9,

AG9H, AG40, DG2, DG6,

and D12B

WARNING

Measure low-fire pressure at

this location only for units

with electronic modulation

gas control Option AG8, AG9,

AG9H, AG40, DG2, DG6, or

D12B).

1/4” NPT

Pressure

Tap

2) Measure High Fire Pressure and Adjust (if needed)

Open the manual valve and operate the heater.

Using the manometer connected to the single-stage valve, measure the outlet pres-

sure. To ensure an accurate high-fire gas pressure reading at the single-stage valve, a

minimum 20VDC signal MUST be present at the modulating gas valve.

Normally, when operating at the altitude indicated on the rating plate, adjust-

ments to the factory settings should not be necessary. If adjustment is required,

remove the cap from the adjustment screw on the single-stage valve. Adjust pressure

setting by turning the regulator screw IN (clockwise) to increase pressure. Turn regu-

lator screw OUT (counterclockwise) to decrease pressure. If an adjustment is made,

turn up the thermostat. Cycle the burner once or twice to properly seat the adjustment

spring in the valve. Re-check the pressure. When the outlet pressure is right for the

installation, remove the manometer and replace the cap. Check for a leak at the pres-

sure tap fitting.

WARNING

Valve outlet gas pressure must never exceed the value listed

in TABLE 11 (or as shown on the rating plate).

3) Measure Low Fire (Bypass) Pressure

To measure low-fire (bypass pressure) on electronic modulation gas control Options

AG8,AG9, AG9H, AG40, DG2, DG6, and D12B, disconnect one of the wire leads to the

modulating valve. Measure the pressure with the manometer attached to the pressure

tap just behind the orifice adapter (

FIGURE 11C). Re-connect the wire.

DO NOT attempt to adjust the bypass (low-fire) pressure. If bypass pressure is incor-

rect (see

TABLE 11, page 20), contact the factory.

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result in

unregulated manifold

pressure causing

excess overfire and

heat exchanger

failure.

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result in

unregulated manifold

pressure causing

excess overfire and

heat exchanger

failure.

6.0 Mechanical

(cont’d)

6.1 Gas Piping and Pressures - Models RDH and RHH (cont’d)

6.1.2 Checking Burner Gas Pressure (cont’d)

INSTRUCTIONS for ELECTRONIC MODULATION Gas Control Options AG58 and

D12G)

1) Measure the Manifold Pressure

Turn the manual valve in the gas line off.

Locate the manifold pressure tap; see

FIGURE 12. Remove the bushing and connect

a manometer to the 1/8" pressure tap.

Turn on the manual gas valve. Operate the unit with a call for heat. Verify that the

actuator has fully opened the ball valve (highest fire). The ball valve is fully open when

the dash marks on the actuator are aligned with the gas piping. With the burner at high-

est fire, measure the manifold pressure. The manifold pressure should be 3.4" w.c. for

natural gas or 10” w.c. for propane.

2) Adjust Pressure at the Single-Stage Valve (if needed)

Turn the manual gas valve off. On the single-stage gas valve (see FIGURE 11A,

page 17), locate the 1/8” output pressure tap and attach a manometer.

Turn on the manual gas valve. Operate the unit with a call for heat. Check the outlet

pressure of the valve with the burner at full fire. Pressure should be 3.5” w.c for natural

gas or 10” w.c. for propane.

If adjustment is necessary, remove the cap from the

adjustment screw. Set pressures to correct setting by turning the regulator screws IN

(clockwise) to increase pressure. Turn regulator screws OUT (counterclockwise) to

decrease pressure.