0 mechanical (cont’d), Table 21 - evaporative cooling module dimensions – Reznor RXH (Outdoor PreevA) Unit Installation Manual User Manual

Page 32

Form I-RDH/REH/RHH/RXH (12-14), Page 32

Water Supply - Connect the water supply to the 1/2” NPT male connection on the

control side of the evaporative cooling module. See location in

FIGURE 25. Install a

manual water shutoff valve upstream of the cooling module inlet at a convenient non-

freezing location. If necessary, install a bleed line between the manual valve and the

cooling module to allow drainage of the line between the shutoff valve and the cooling

module.

Fill and Drain Kits (field installed) - If the module has a pump and float water control

system and is ordered with a fill and drain kit (Option CT1, CT2, or CT3), refer to the

illustration in

FIGURE 26, page 33, to install the automatic fill and drain valves. Refer

to the system wiring diagram to make wiring connections.

CAUTION: Water

reservoir must be

drained and pump

motor turned off

when outside

temperature falls

below 32°F (0°C).

Pump must never

be operated without

water in the reservoir.

See Hazard Levels,

page 2.

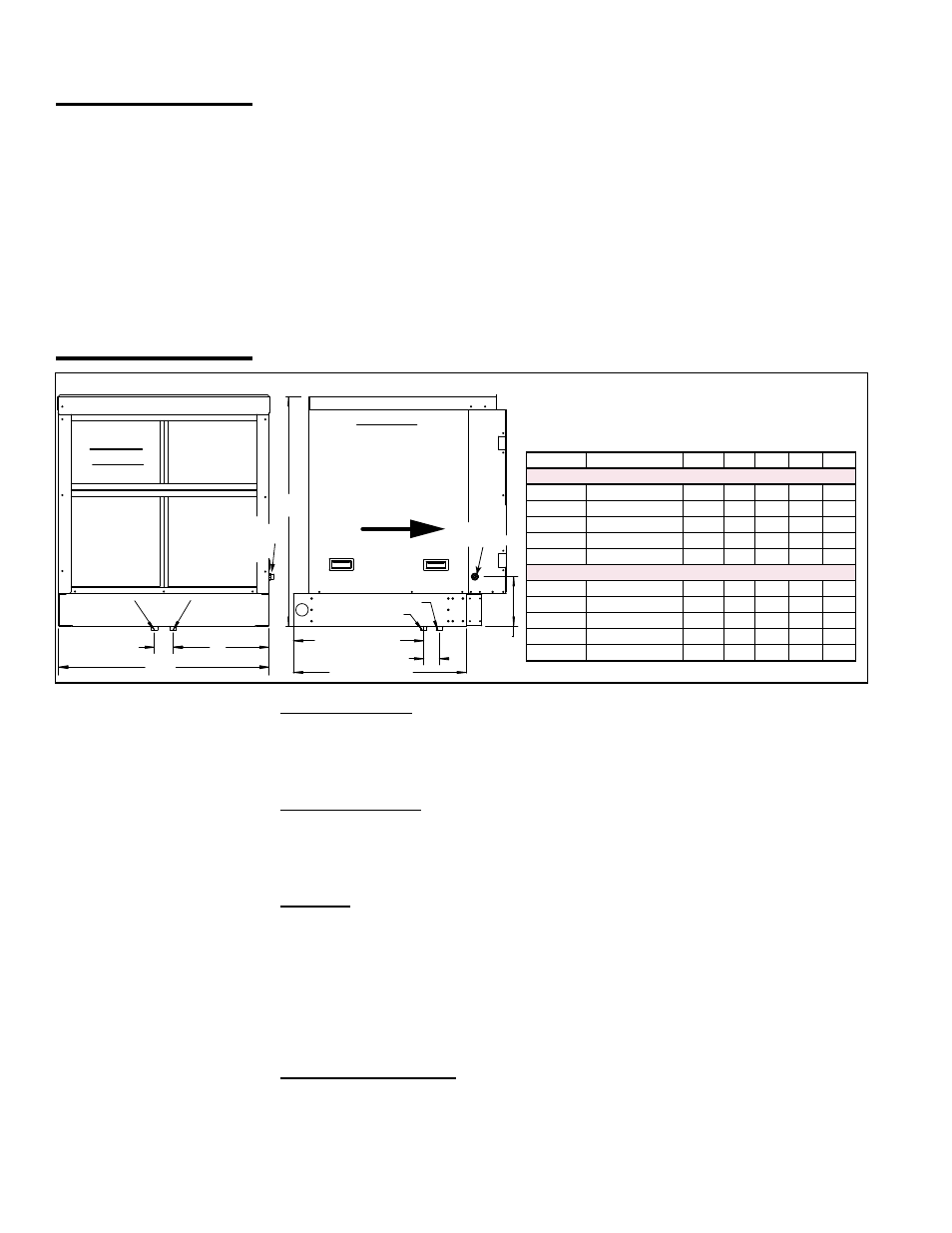

FIGURE 25 - Evaporative Cooling Module Dimensions and Water Connection Locations

A

C

B

Water

Connection

1/2” NPT

Removable Panel -

Control and Media

Access

Side View

Entering

Air View

Overflow

Connection,

3/4” NPT Male

Drain

Connection,

3/4” NPT Male

Drain

Overflow

Water

Connection

Airflow

3 (76)

20-7/8 (531)

2-1/2 (64)

27-3/4 (705)

7-15/16

(202)

TABLE 21 - Evaporative Cooling Module

Dimensions

RDH

REH

RHH

RXH

A

B

C

Dimensions - inches

75/100

10A/20A/40A

N/A

000A 33-3/4 34-1/2 15-3/8

125/150

15B/30B/60B

N/A

000B 43-3/4 34-1/2 20-3/8

175/200/225

N/A

130/180 000C 33-3/4 43-3/4 15-3/8

250/300

30D/60D/90D/120D

260

000D

50

43-3/4 23-1/2

350/400A

40E/80E/120E

350

000E

58

43-3/4 27-1/2

Dimensions - mm

75/100

10A/20A/40A

N/A

000A 857

876

391

125/150

15B/30B/60B

N/A

000B 1111

876

518

175/200/225

N/A

130/180 000C 857

1111

391

250/300

30D/60D/90D/120D

260

000D 1270 1111 597

350/400A

40E/80E/120E

350

000E 1473 1111

699

Follow these instructions to field connect the water supply and make necessary checks

and adjustments before operating the evaporative cooling module.

NOTE: See TABLE 5, page 10 for evaporative cooling module weights.

6.0 Mechanical

(cont’d)

6.5 Optional Evaporative Cooling Module (factory installed)

(cont’d)

Freeze Protection - If a freeze protection option was ordered, the fill valve will not

operate at subfreezing temperature.

NOTE: On an evaporative cooling module with a

recirculating pump and float water control system, freeze protection is only available

if an optional fill and drain kit is field installed. See

Operating Sequence Section in

FIGURE 26, page 33.

Overflow and Drain - All evaporative cooling modules are equipped with an overflow

and drain fitting. The fittings are in the cabinet bottom and come complete with a lock

nut and a sealing gasket. Check these fittings for tightness before installing the over-

flow and drain piping. The drain and overflow fitting will accommodate 3/4” NPT fittings

and are also tapped with a 1/2” female pipe thread for iron pipe.

Bleed Off - If the module has a recirculating pump and float water control sys-

tem, it has a bleed off hose. The bleed off hose is attached to a tee in the fill line and

must drain into the overflow drain. Make sure that the end of the bleed off line extends

into the overflow drain. Adequate bleed off is important to maintaining an efficiently

operating system by lessening the concentration of undesirable minerals in the water

being circulated through the cooling module. Minerals buildup because evaporation

only releases “pure water vapor” causing the concentration of contaminants in the

water to increase as the evaporation process continues. The minerals accumulate on

the media, in the water lines, on the pump, and in the reservoir.

Water Hammer Arrestor - If the cooling module is equipped with an AquaSaver

timed metering system, the operation of the solenoid valve in the water line is con-

trolled by the timer. Due to various water pressures and installation conditions, the

water supply line may bang abruptly when the solenoid valve closes. This banging can

be minimized by installing an optional water hammer arrestor (Option ECB1) in the

supply line. When installing an optional water hammer arrestor, select an indoor loca-