0 mechanical (cont’d) – Reznor RXH (Outdoor PreevA) Unit Installation Manual User Manual

Page 34

Form I-RDH/REH/RHH/RXH (12-14), Page 34

6.5.2 Adjusting Water Flow Over Pads

Proper water flow over the evaporative cooling media is critical to extend the life and

maintain the

efficiency of the pads. Read the warnings and follow the instructions that

apply.

CAUTION: Do not flood the media pads with extreme quantities of

water for long periods as this will cause premature breakdown of

the media. An even flow from top to bottom of the media with the

least amount of water is all that is required to assure maximum

efficiency and media life span. More water does not provide more

evaporation or more cooling.

WARNING

Adjust ball

valve only when

the power is

disconnected from

the system. Failure

to do so can cause

electrical shock,

personal injury, or

death.

Adjusting Water Flow with a Float and Pump Control System - Using the ball

valve, located in the length of hose running from the pump to the distribution line inlet

(See

FIGURE 28), adjust the valve handle to allow the flow to completely dampen the

media pads from top to bottom.

Operate the unit watching the water flow. After 15 minutes with the blower in operation,

the water should have completely dampened the pads but should not be flowing off the

entering side of the media. If water is flowing off the entering side of the media, turn the

system off, disconnect the power, and reduce the entering water flow.

Adjusting Water Flow with a Timed Metering Control System - NOTE: Water flow

and pad wetting time should be adjusted at maximum airflow and wet bulb depression

to assure complete wetting of the media at the extreme operating conditions.

In addition to adjusting water flow, the timing of the water on/off cycle can be adjusted.

Adjustments are correct when

l) the water rises from the holes in the sprinkler pipe

consistently along the entire pipe length,

2) the media pads wet evenly after a few “ON”

cycles (no dry spots or dry streaks), and

3) a slight amount of excess water collects at

the drain at the completion of the “ON” cycle.

FIGURE 28 - Remove

side door and locate

ball valve (illustration

below is from the

rear). Both water flow

control systems have

a ball valve in the

water line.

Ball

Valve,

P/N

207468

PVC Sprinkler Pipe

RDH

Size

REH

Size

RHH

RXH

Size

A = Water rise from

PVC Sprinkler Pipe

75/100/

125/150

10A/20A/40A/

15B/30B/60B

N/A

000A/

000B

1/8” to 1/2”

3 to 13mm)

175/200/

225/250/

350/ 400A

30D/60D/90D/

120D/40E/80E/

120E

130/180/

260/350

000C/

000D/

000E

1/4” to 1/2”

(6 to 13mm)

FIGURE 29 - Timed Water System - Use the ball valve in FIGURE 28 to

adjust the rise from the distribution (sprinkler) pipe in the evaporative

cooling module.

1) AquaSaver Water Flow Adjustment - Using the ball valve illustrated in FIGURE

28, adjust the water flow so that the water rises above the distribution pipe as illus-

trated in

FIGURE 29.

A

2) AquaSaver Timer Adjustment - At any given temperature, the media pads should

completely wet from top to bottom during the ON cycle. The microprocessor has three

preset timing settings based on media size. The appropriate setting is selected by

changing the position of the suitcase jumper at J2 on the microprocessor. Remove the

cover to check the setting (See

FIGURE 30).

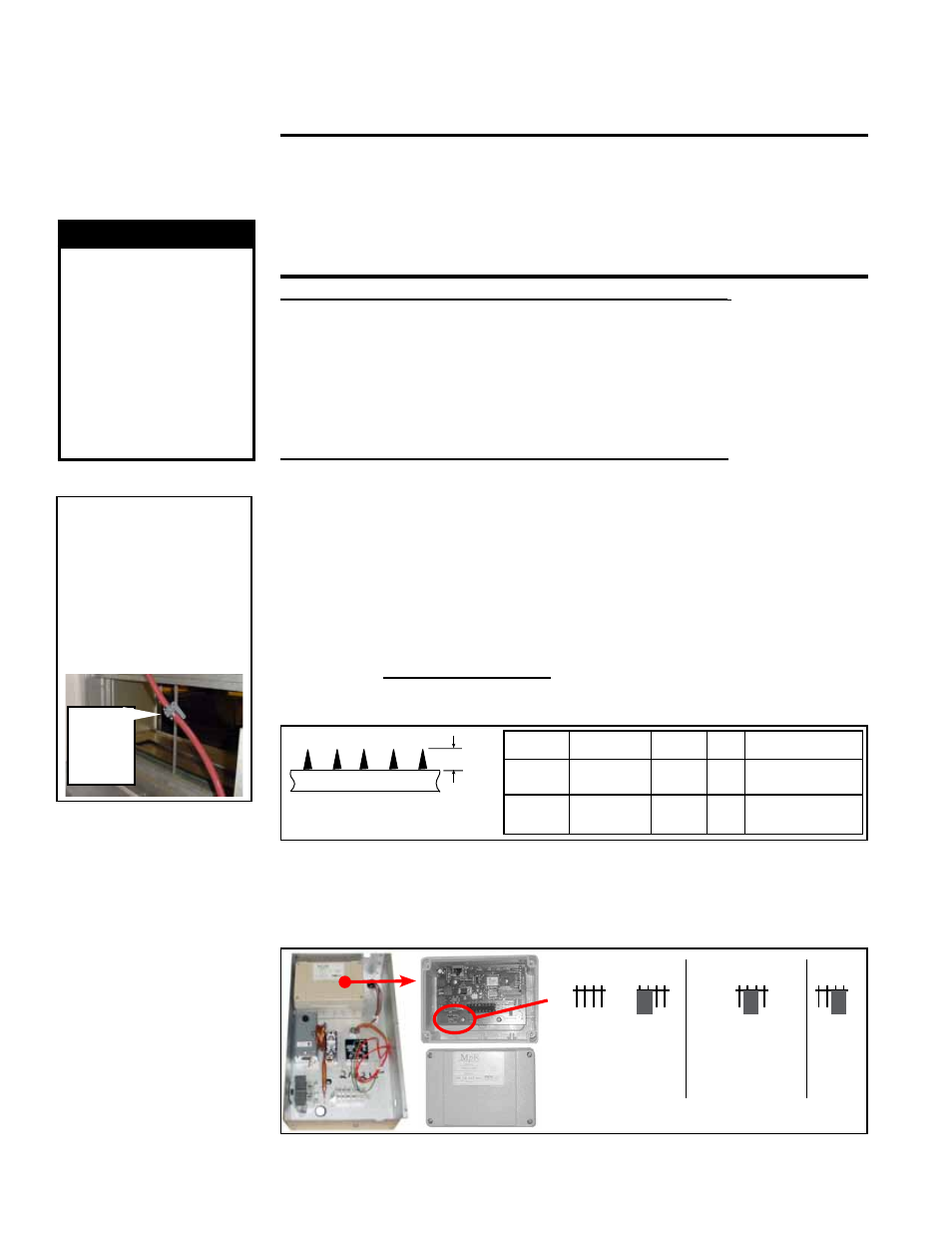

FIGURE 30 - AquaSaver

Microprocessor

Control, P/N 205044, in

the Junction Box

J2

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

S

M

L

RDH 75/100/

125/150

REH 10A/20A/

40A/15B/

30B/60B

RXH 000A/000B

RDH 175/200/225/ 250/

275/300/350/400A

REH 30D/60D/90D/

120D/40E/80E/120E

RHH 130/180/260/350

RXH 000C/000D/000E

If the jumper is at the appropriate location, replace the cover. If the jumper needs to be

moved, move it to the appropriate setting. The setting will go into effect when the power

6.0 Mechanical

(cont’d)

6.5 Optional

Evaporative

Cooling Module

(factory installed)

(cont’d)