2 clearances, 0 suspension and mounting, 1 weights – Reznor RPBL Unit Installation Manual User Manual

Page 8: 2 suspension - model sscbl, 3 indoor mounting on field-supplied supports, 0 dimensions and clearances (cont'd)

Form I-SSCBL/RPBL, Page 8

4.2 Clearances

For safety and convenience, provide clearances as shown in the table. Clearance to

combustibles is defined as the minimum distance from the heater to a surface or object

that is necessary to ensure that a surface temperature of 90°F above the surround-

ing ambient temperature is not exceeded. Minimum clearances are also listed on the

heater rating plate.

Required

Clearances -

inches (mm)

Model

SSCBL

Side Opposite Controls - 6" (152mm) is required for clearance to combustibles.

30" (762mm) service clearance is recommended for access to the motor.

Control Side (for service) - 56" (1422mm)

Top - 6" (152mm)

Furnace Bottom - 6" (152mm)

Model

RPBL

Control Side (for service) - 56" (1422mm)

Side Opposite Controls - 30" (762mm) service clearance is recommended for access

to the motor.

*Furnace Bottom - 0" (0mm)

*When installed on a roof curb on a combustible roof, the roof area enclosed within the curb must be either

ventilated, left open, or covered with non-combustible material which has an "R" value of at least 5.0. See

FIGURE

9A, page 11.

5.0 Suspension

and Mounting

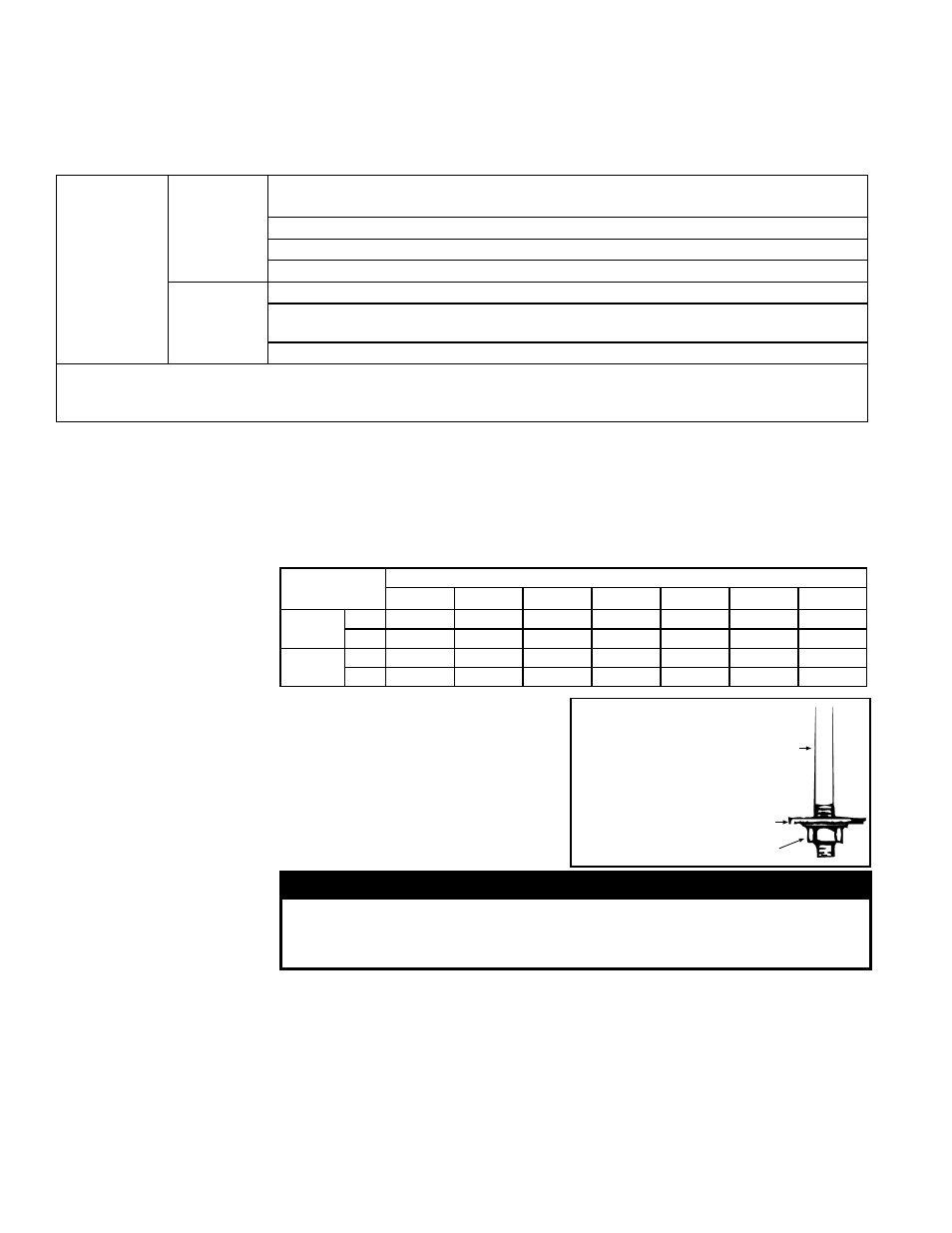

5.1 Weights

Before installing, check the supporting structure to be sure that it has sufficient load-

carrying capacity to support the weight of the unit. Properly suspending or mounting

the unit is the responsibility of the installer. Model SSCBL systems are designed for

either suspension or mounting. Model RPBL systems are designed for mounting only.

All installed systems must be level.

Model and

Size

Net Weight (lbs and kg)

400

500

600

700

800

1050

1200

SSCBL lbs

849

1104

1104

1184

1245

1476

1565

kg

385

500

500

537

565

670

710

RPBL

lbs

849

1104

1104

1184

1245

1476

1565

kg

385

500

500

537

565

670

710

A Model SSCBL unit is equipped with a

load-bearing curb cap which forms an

integral part of the unit. The curb cap is

welded at all joints and has suspension

holes at each corner and hanger brack-

ets on the sides. See

FIGURE 2 for sus-

pension dimensions. Each suspension

location requires a 1/2" threaded rod as

illustrated in

FIGURE 5.

5.3 Indoor

Mounting on

Field-Supplied

Supports -

Model SSCBL

Prior to installation, be sure that the method of support is in agreement with all local

building codes. Whether the supports are being mounted directly on a surface or being

placed "up" on additional structure, the horizontal length of the system should be sup-

ported by two 4x4 treated wooden rails. Cut the rails to the appropriate length (Dimen-

sion "A" in

FIGURE 6A).

Space the 4x4 wooden rails (See "B" Dimension,

FIGURE 6A) so that the curb cap

"skirt" will fit over the edge of the boards with the rails setting inside the horizontal

length of the curb cap.

If the rails are being laid directly on a surface, position them as shown in

FIGURE 6B.

Set the system on the rails, leaving the "ends" underneath open for ventilation.

1/2

Threaded

Rod

Lockwasher

1/2-13 Nut

FIGURE 5 - Support

Rod Detail -

Required at all

Suspension

Points

4.0 Dimensions

and Clearances

(cont'd)

5.2 Suspension -

Model SSCBL

WARNING

Units must be supported level for proper operation. Do not place

or add additional weight to the suspended unit. See Hazard Levels,

page 2.