11 burner air shutters, 0 check installation and start-up, 1 check the installation prior to start-up – Reznor RPBL Unit Installation Manual User Manual

Page 52: 0 controls (cont'd)

Form I-SSCBL/RPBL, Page 52

8.11 Burner Air

Shutters

Size

Burner Orifices (sea level)

Propane

Carryover Orifice

Qty per

Furnace

Natural Gas

Propane

Drill Size

P/N

Drill Size

P/N

Drill Size

P/N

500

12

#44

11833

#55

11830

#59

10370

600

12

#42

84437 1.45 mm 61652

#59

10370

700, 1050

14

#42

84437 1.45 mm 61652

#56

9791

400, 800, 1200

16

#42

84437 1.45 mm 61652

#56

9791

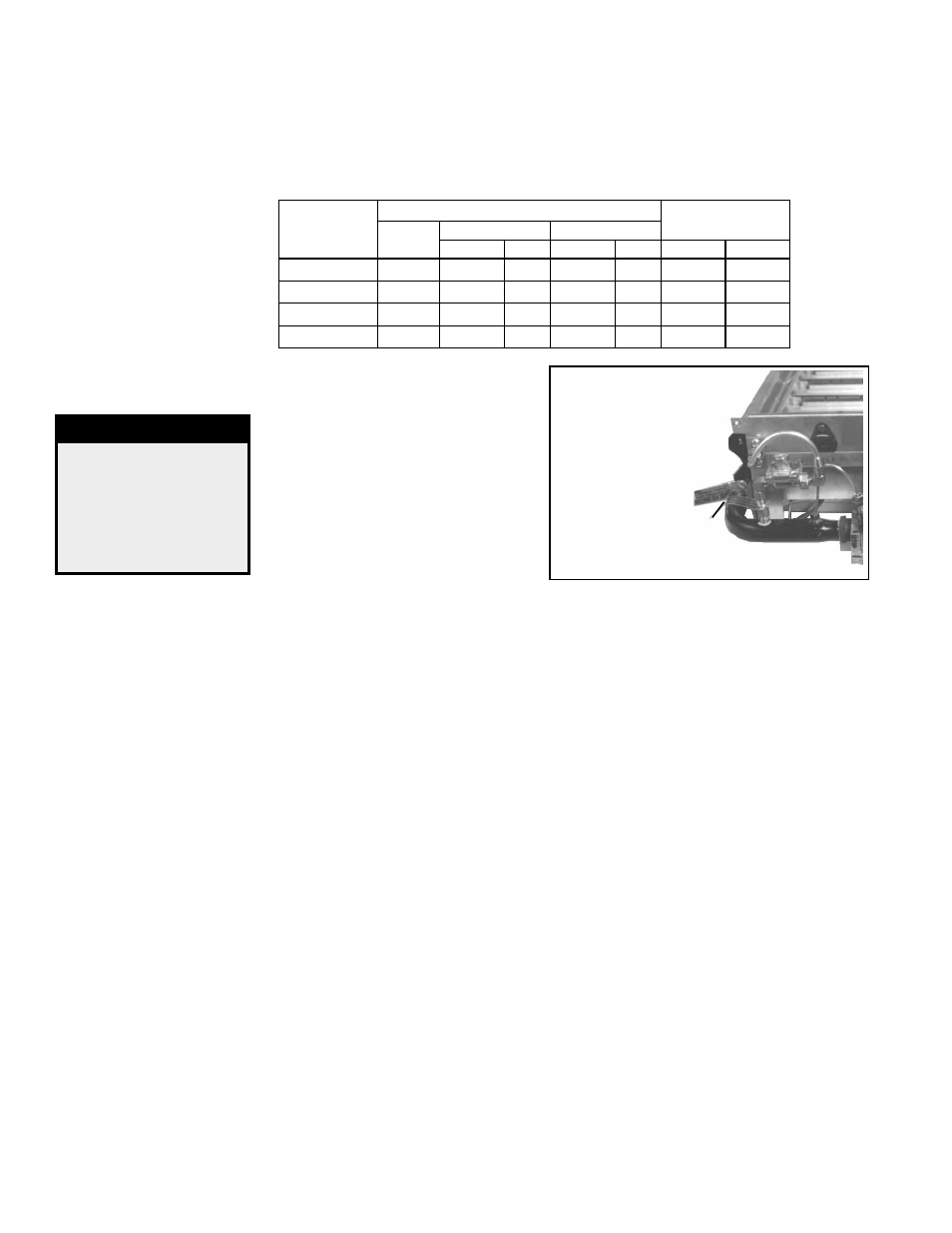

Air shutters are required on propane

units, optional on natural units. A slot-

ted screw on the end of the manifold

bracket moves air shutters and adjusts

all burners simultaneously (See

FIG-

URE 56.) Turning the screw clockwise

opens the air shutter; counterclock-

wise closes shutter.

After the furnace has been in opera-

tion for 15 minutes, close air shut-

ter until the flame turns yellow. Open

shutter until yellow disappears.

Burner Air Shutter

Adjustment Screw

FIGURE 56 -

Propane Burner

Rack Showing

Burner Air Shutter

Adjustment Screw

DANGER

Failure to adjust air

shutters according

to directions could

cause property

damage, personal

injury, and or death.

9.0 Check

Installation

and Start-Up

9.1 Check the installation prior to start-up:

Verify suspension/mounting methods and clearances. See Paragraphs 4.0 & 5.0.

Check the duct connection. See Paragraph 6.4.

Check venting. See Paragraph 6.2. Be sure that flue discharge and combustion air

openings are free of obstructions. Be sure electrical entrance and gas supply pipe

openings are sealed.

Electrical Checks:

Be certain the electrical supply matches voltage rating of the furnace. (Refer to the

rating plate.)

Check all field wiring against the wiring diagram. Be sure that wire gauges are as

required for the electrical load.

Check that fuses or circuit breakers are in place and sized correctly.

Option AG41 or AG42 - set the heat stage controllers. See Paragraph 8.7.4.

Gas Supply Checks:.

Check piping for leaks and proper gas line pressure. Bleed gas lines of trapped air.

See Paragraph 6.1.

a) Turn manual shutoff valve to off position.

b) Turn gas supply on.

c) Observe gas meter for movement, or

d) Attach pressure gauge readable to .1" w.c. and after turning gas on for ten

seconds, turn gas supply off. No change in pressure should occur over a three-

minute period.

e) If either c) or d) above indicate a leak, locate leak by brushing a soapy solution

on all fittings. Bubbles will appear at a leak. Repair and repeat tests.

Blower Checks:

Check blower pulley and motor pulley to be sure they are secure to the shafts.

Check belt tension and alignment. Check blower rotation. See Paragraph 6.5.

With optional dampers - Check damper linkage. See Paragraph 6.3.3.

8.0 Controls

(cont'd)

8.10 Burners,

Orifices, and

Carryover

System

(cont'd)

All

propane gas burners are equipped with one flash carryover and a regulated gas

lighter tube system. The carryover lighter tube receives its gas supply through a regula-

tor, simultaneously with the gas to the burner orifices.

During regular service, check the main burner ports, the carryover assemblies, and the

orifices for cleanliness.

Burner Orifices - Heaters are shipped with orifices of proper size and type for gas

specified.

NOTE: Natural gas units do not require a carryover orifice.