Reznor RPBL Unit Installation Manual User Manual

Page 31

Form I-SSCBL/RPBL, P/N 149159 R7, Page 31

The optional dirty filter pressure switch is used to provide warning to the user by ener-

gizing an indicator light on an optional remote console. The light indicates that the

filters are in need of cleaning or changing. The adjustable, single-pole/normally open

differential switch closes when an increase in pressure differential above the setpoint,

is sensed across the filter bank.

This switch is located in the furnace section. See page 43,

FIGURE 46, Item 17. After

the unit is started, before continuous operation, the dirty filter switch must be set.

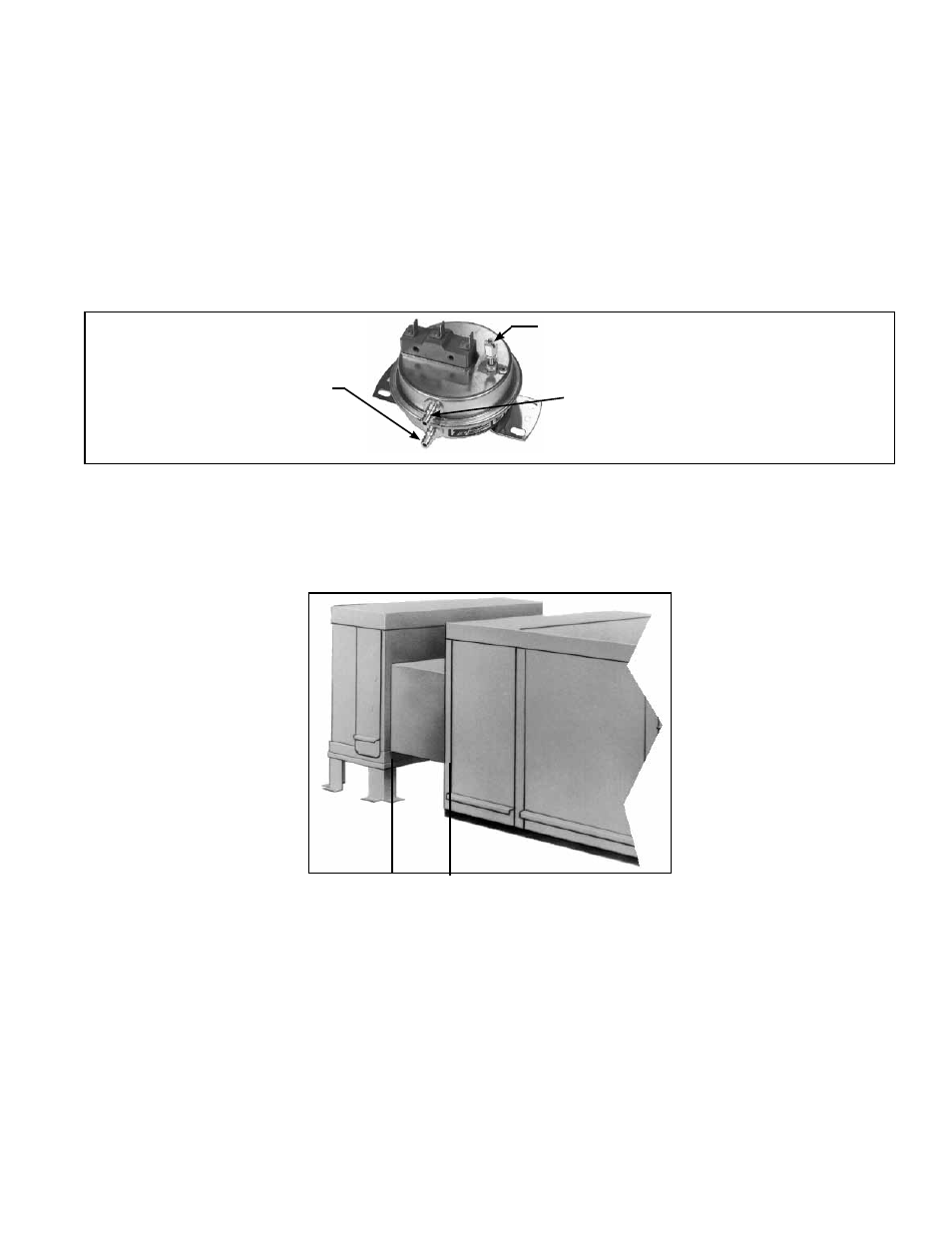

Instructions for Setting Dirty Filter Switch (FIGURE 33)

With clean filters in place, blower doors closed, and blower in operation, decrease the

pressure setting by adjusting the set screw on the switch clockwise until the filter light

is energized or the screw is bottomed out. At that point, adjust the set screw three full

turns counterclockwise or until the screw is top-ended. At that setpoint the filter light will

be activated at approximately 50% filter blockage.

FIGURE 33 - Dirty Filter

Switch

Set screw (on front of switch) must be

manually adjusted after the system is

in operation.

Negative pressure connection is

toward the "front" or "top" of the

switch (senses blower side of filters)

Positive pressure connection

is toward the "back" or

"bottom" of the switch

(senses air inlet side of filters)

6.3.5 Optional

Evaporative Cooling

Module - Applies to

Model RPBL

Blower Cabinet

Cooling

Module

and Base Connecting

Duct

FIGURE 34 - Optional

Evaporative Cooling

Module is factory-

assembled for field

attachment to the

blower cabinet (duct

and base are shipped

knocked down for field

assembly)

Evaporative cooling provides excellent comfort cooling at low initial equipment and

installation costs and low operating and maintenance costs. Direct evaporative cool-

ing works solely on the principle that water in direct contact with a moving airstream

will eventually evaporate if the droplets have long enough exposure. This evaporative

cooling module uses wetted rigid cellulose or glass fiber media to retain water in order

to allow time for evaporation.

The evaporative cooling module for these systems is factory assembled but is not

attached to the blower cabinet at the factory. It is shipped separately for field attach-

ment to the system blower cabinet. The base support for the cooling module and the

transitional ductwork between the cooling module and the blower cabinet inlet are

shipped separately and must be field assembled and installed. Complete installation

instructions including water and electrical connections are included with the evapora-

tive cooling module package.

Included in the cooling module installation booklet is a preparation checklist. All items

in that checklist should be consulted prior to beginning installation of the optional evap-

orative cooling module. Four of those items are listed below.

Make certain the supporting platform is capable of handling the additional load of a

full cooling module reservoir.

Weights of Evaporative Cooling Module - w/Wet Media & Full Reservoir (lbs.)

Module with 12" rigid cellulose media (Opt AS4) 431 lbs

Module with 12" rigid glass fiber media (Opt AS8) 514 lbs

Optional Dirty Filter

Switch