9 pilot and ignition systems, 10 burners, orifices, and carryover system – Reznor RPBL Unit Installation Manual User Manual

Page 51

Form I-SSCBL/RPBL, P/N 149159 R7, Page 51

8.9 Pilot and

Ignition

Systems

Ignition System - Natural gas units are equipped with a spark ignited intermittent

safety pilot system that shuts off the pilot gas flow between heat cycles. Propane units

(or as an option on natural gas units) require a lockout device that stops the gas flow to

the pilot if the pilot fails to light in 120 seconds. The lockout device has a 1-hour retry

or requires manual reset by interruption of the thermostat circuit. Refer to the wiring

diagram supplied with the unit for pilot system identification and proper wiring. Pilot

with lockout is Option AH3; non-lockout spark pilot is Option AH2.

Ignition Controller - As part of the intermittent safety pilot systems, the ignition con-

troller provides the high voltage spark to ignite the pilot gas and also acts as the flame

safety device. After ignition of the pilot gas, the ignition controller electronically senses

the pilot flame. A low voltage DC electrical signal is imposed on the separate metal

probe in the pilot assembly. The metal probe is electrically insulated from ground. The

pilot flame acts as a conduction path to ground completing the DC circuit and proving

pilot flame. With pilot flame proven, the ignition controller energizes the main gas valve.

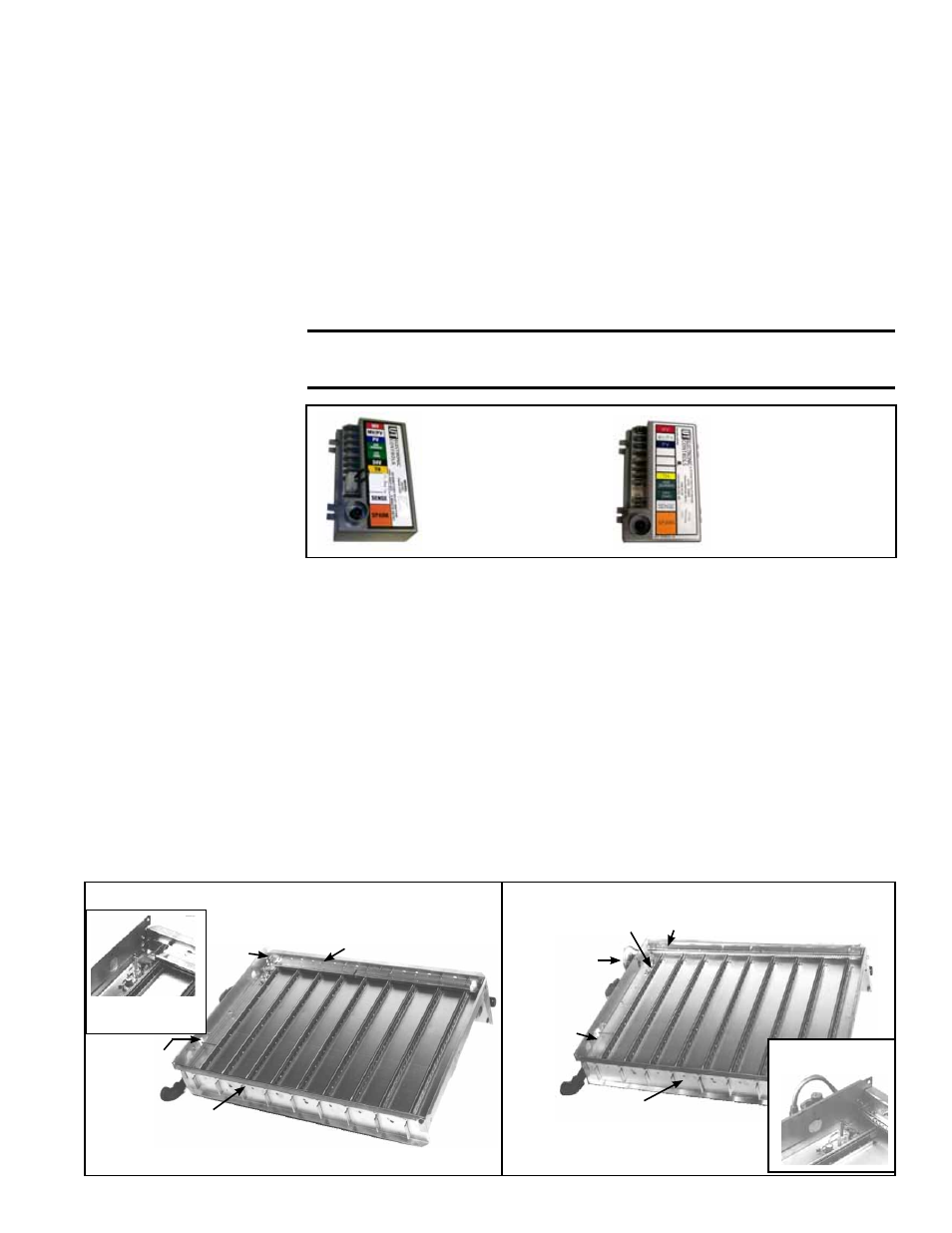

Ignition Controller

with Lockout, UTEC

1003-514, P/N

257010, for Option

AH3 Gas Control

Recycling Ignition

Controller, UTEC

1003-638A, P/N

257009, for Option

AH2 Gas Control

Service NOTE: If replacing

an earlier model of ignition

controller, order replace-

ment kit

P/N 257472 for

a unit with recycling gas

control Option AH2 or

P/N

257473 for Option AH3 gas

control with lockout. (Option

codes are listed on the unit

wiring diagram.)

CAUTION: Due to high voltage on pilot spark wire and pilot electrode, do

not touch when energized. See Hazard Levels, page 2.

Pilot - All pilots are vertical, target type with lint-free feature. Pilot flame should be

approximately 1-1/4" in length. Pilot gas pressure should be the same as the supply

line pressure. Pilot gas is supplied through the combination valve; the pilot gas flow

is controlled by an adjustment screw located in the valve body. For maintenance, see

Paragraph 10.2.2.

8.10 Burners,

Orifices, and

Carryover

System

Burners - Individually formed steel burners capable of operating on either natural or

propane gas are used in this heater. These burners have accurate, machine-formed

ports to give controlled flame stability and operation without lifting or flashback. All

burners are lightweight and factory mounted in an assembly which permits all of the

burners to be removed as a unit for inspection or service.

Burner Carryover Systems (FIGURES 54 and 55) - All natural gas burners (except

when equipped with electronic modulation Option AG39, AG40, AG41 or AG42; see

Paragraph 8.8.4) are equipped with two flash carryover systems, one on each end of

the burner rack. (

NOTE: A natural gas burner rack on furnaces manufactured prior to

Series 6 had a gas lighter tube carryover and one flash carryover.)

Pilot

Auxiliary

Sensor

Flash Carryover

Flash

Carryover

FIGURE 54 - Natural Gas Burner Rack

Carryover Lighter Tube

Pilot

Carryover

Regulator

Flash

Carryover

Propane Pilot

Auxiliary

Flame

Probe

FIGURE 55 - Propane Burner Rack with Lighter

Tube

Natural Gas

Pilot

FIGURE 53 - Ignition

Controllers