Reznor RPBL Unit Installation Manual User Manual

Page 33

Form I-SSCBL/RPBL, P/N 149159 R7, Page 33

45°

Airflow

to S

pace

Out

side

Airflow

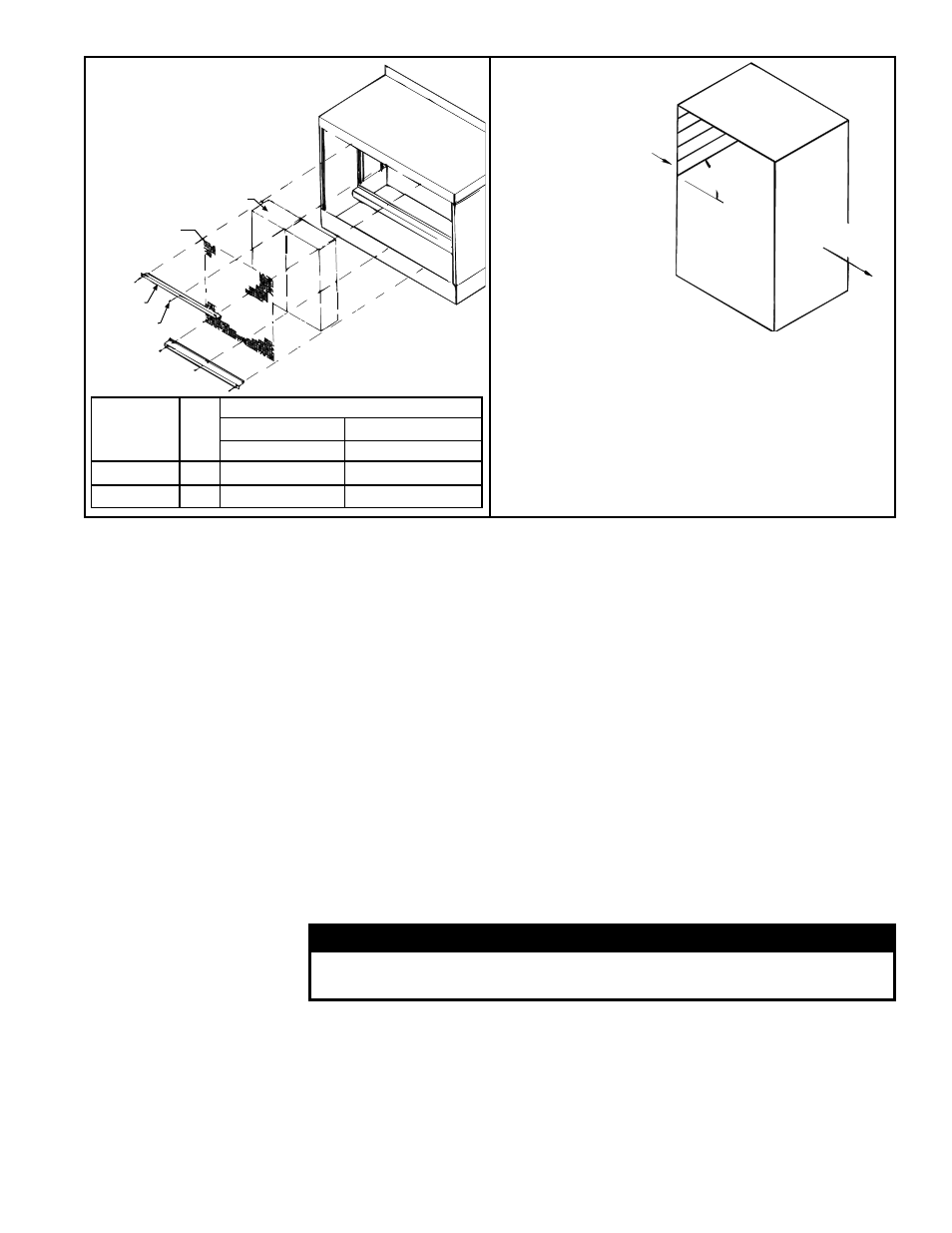

FIGURE 37 -

Media must be

installed with 45°

angle sloping

downward toward

the incoming

outside air.

IMPORTANT: The media is made up of two

different sheets of cooling material. Each sheet

has its own unique angle. When replacing the

cooling media, BE CERTAIN that the 45° angle

slopes downward toward the incoming outside

air (as illustrated above). If the media is not

installed properly, water blowoff from the media

pads will occur.

Pad

Screen

Pad

Retainer

Screw

Media

Pad Sizes

(inches)

Qty

Replacement Part No. (each)

Rigid Cellulose Rigid Glass Fiber

12"

12"

48 x 12

4

107194

107201

48 x 8-5/8

1

107195

107202

FIGURE 36 - Removal

and Replacement of

Evaporative Cooling

Module Media

8. Replace the two side screen retainers by fitting them between the side of the

media pad and the side of the cooling module. The retainers should fit snugly,

pinching the screen against the media pads.

9. Replace the bottom pad retainer by securing the retainer between the pad and the

reservoir pan. Fasten with the three sheetmetal screws removed in Step 2.

10. Replace the top pad retainer by securing the retainer between the pad and top of

the cooling module. Fasten with the three sheetmetal screws removed in Step 1.

Water Feed Line and Distribution Piping – Annually, the water supply line and the

water distribution line (either PVC pipe or water sock) should be flushed of debris and

contaminants.

1. Remove the media pads following the instructions above.

2. Remove the water feed line from the downstream side of the ball valve and

unscrew the water bleed line barbed hose fitting.

3. Force a fresh water supply up through the water inlet hose and thoroughly flush

the distribution line.

4. Re-assemble, being careful to install media with air flow direction as shown in

FIGURE 37.

Water Pump and Inlet Basket Screen (Does not apply to module with optional timed

metering system.)

– Annually, the pump and inlet basket should be removed, disas-

sembled and cleaned.

WARNING

Do not expose pump motor or any part of the electrical box to

water. Evaporative cooling pump is NOT submersible.

1. Disconnect the power supply to the unit.

2. Remove the junction box door and disconnect the two power supply wires from

the terminal block inside the junction box.

3. Disconnect the water feed line hose from the upstream side of the ball valve.

4. Unscrew the four sheetmetal screws holding the junction box to the cooling

module. Remove the junction box-pump-float switch assembly.

5. Dislodge the inlet basket screen from the pump and clean any buildup of debris

and dirt. Carefully remove the base cover plate from the bottom of the pump.