Reznor RPBL Unit Installation Manual User Manual

Page 47

Form I-SSCBL/RPBL, P/N 149159 R7, Page 47

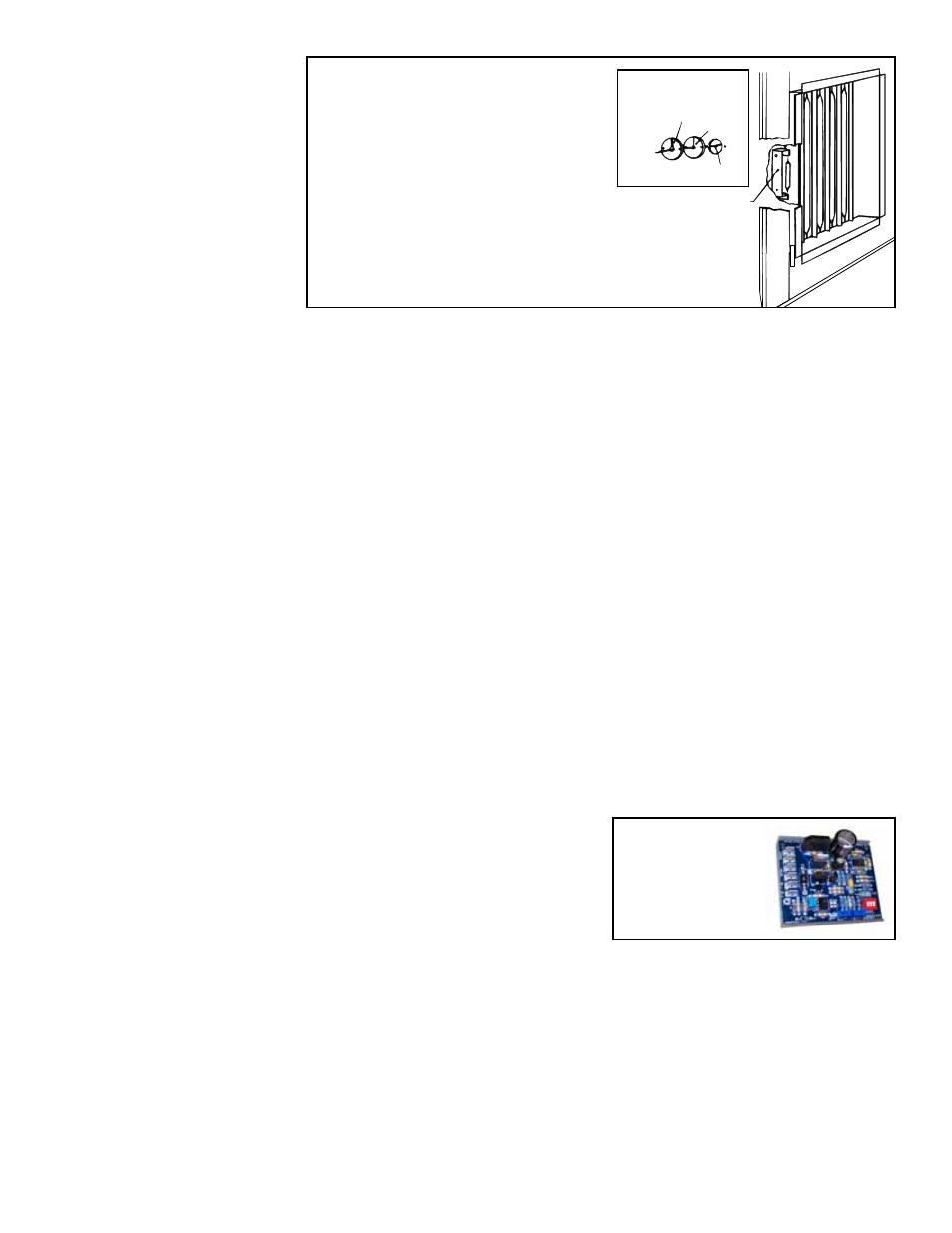

Sensor Bracket

(NOTE: Bracket

may not be the

same as the one

illustrated.)

Sheetmetal

Retaining

Plate

Gasket

Sensor Capillary

1. Remove access panel in the ductwork

adjacent to the control compartment

access panel.

2. Element is retained by either spring

clips or cable straps.

3. Round gasket and metal retaining

plate provide airtight seal for capillary

and must be removed to remove the

element.

FIGURE 49 - Duct Temperature

Sensor Location

8.8.4 Optional

Electronic Modulation

The type and capability of the electronic modulation system depends on the option

selected. Electronic modulation options are identified by a suffix to the Serial No.

printed on the heater rating plate. AG7 is identified as MV-1; AG8 is identified as MV-3;

AG9 is identified as MV-4; AG21 is identified as MV-A; AG39 is identified as MP-1; and

AG40 is identified as MP-2. AG39 and AG40 are available only on Size 400. AG41 is

identified as MP3 and AG42 is identified as MP4. Both AG41 and AG42 apply only to

Sizes 500, 600, 800, and 1200.

Installation Note: Sizes

400, 700, 800, 1050,

and 1200 with electronic

modulation gas controls

require a minimum of 6"

w.c. natural gas supply

pressure.

Electronic Modulation between 50% & 100% Firing Rate

(Options AG7,

AG8, AG9)

Depending on the heat requirements as established by the thermistor sensor, the

burner modulates between 100% and 50% firing. The thermistor is a resistor that is

temperature sensitive in that as the surrounding temperature changes, the Ohms resis-

tance changes through the thermistor. This change is monitored by the solid state

control center (amplifier) which furnishes varying DC current to the modulating valve to

adjust the gas input.

Each modulating valve is basically a regulator with electrical means of raising and

lowering the discharge pressure. When no DC current is fed to this device, it functions

as a gas pressure regulator, supplying 3.5" w.c. pressure to the main operating valve.

Refer to the wiring diagram supplied with the furnace for proper wiring connections.

Electronic modulation for heating controlled by a specially designed room thermo-

stat (60°-85°F) is identified as Option AG7. Electronic modulation control systems for

makeup air applications controlled by a duct sensor and temperature selector (55-

90°F) are identified as either Option AG8 or Option AG9. The temperature selector set-

ting for Option AG8 is on the amplifier; Option AG9 has a remote temperature selector.

Both systems are available with an override thermostat.

Computer Controlled

Electronic Modulation

between 50% and 100%

Firing Rate (Option

AG21)

FIGURE 50 -

Maxitrol

conditioner in

Options AG21,

AG40, and AG42

With this option the furnace is equipped

with a Maxitrol signal conditioner which

operates much the same way as the ampli-

fier above to control the regulator valve.

The conditioner accepts an input signal of

either 4-20 milliamps or 0-10 volts from a

customer-supplied control device such as

a computer. With the dip switches on the

conditioner in the "on" positions, the conditioner accepts a 4-20 milliamp signal. In the

"off" positions, the conditioner accepts a 0-10V signal. The conditioner converts the

signal to the 0 to 20 volt DC current required to control the modulating valve. Tempera-

ture selection is through the computer software.

Electronic Modulation

between 25% and 100%

Firing Rate), Options

AG39, AG40, AG41,

AG42 -

Available only

with natural gas

A Size 400 unit equipped with electronic modulation Option AG39 has a 25%-100%

firing range (4:1 turndown ratio). Option AG41 applies to Sizes 500, 600, and 800 with

two furnaces and Size 1200 with three furnaces. The furnace closest to the blower is

equipped with the electronic modulation option. The other furnace(s) have two-stage

burner control from outside air temperature sensors identified as heat stage control-

lers. Option AG41 provides 6:1 turndown with two furnaces and 8:1 turndown with

three furnaces.