Reznor RPBL Unit Installation Manual User Manual

Page 19

Form I-SSCBL/RPBL, P/N 149159 R7, Page 19

6.2.1.2 Horizontal Vent

Instructions - Model

SSCBL

Components Required - Factory and Field

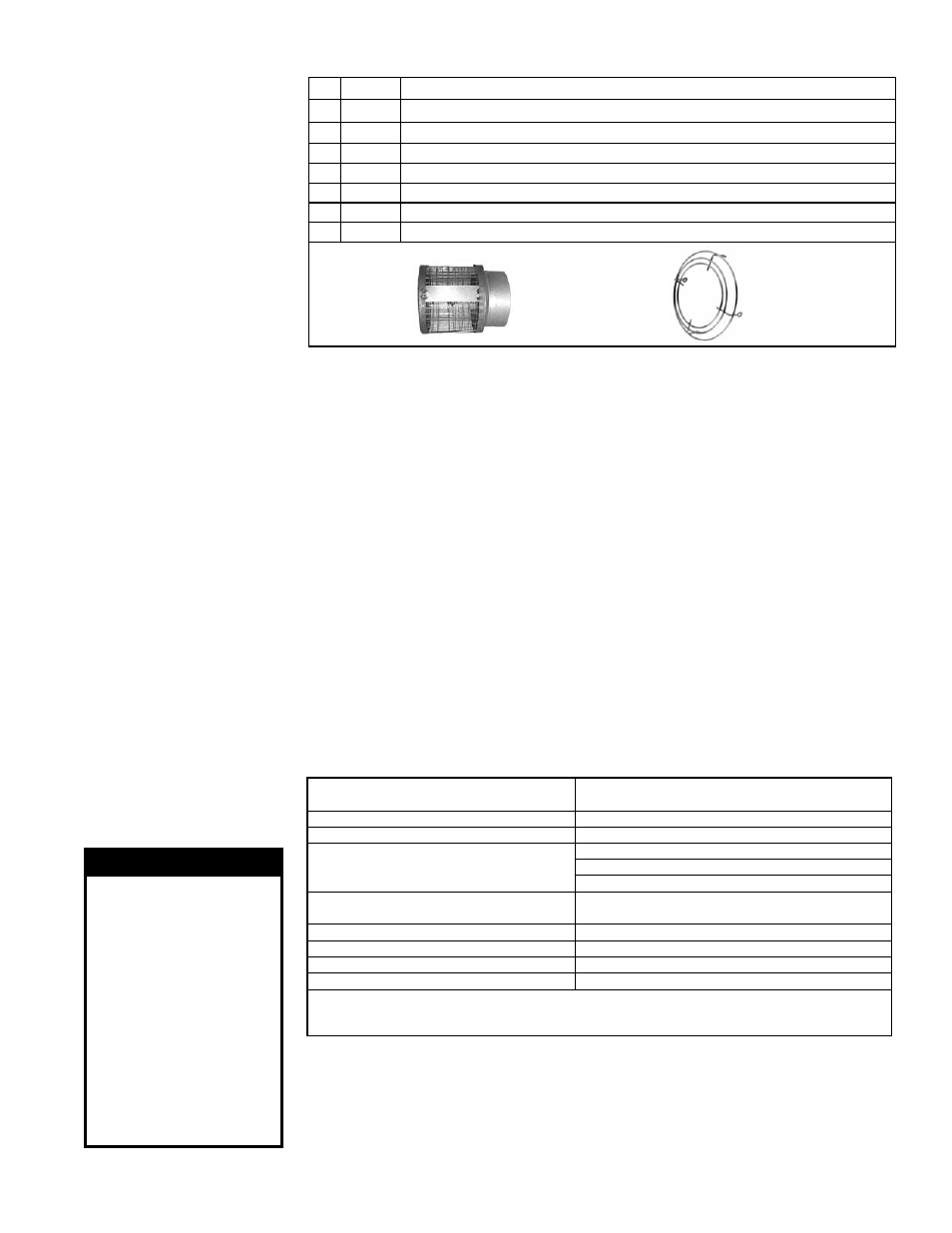

FIGURE 15 - Parts in

each Horizontal Vent

Terminal/Combustion

Air Package (Option

CC6) - One required for

each furnace section.

Field-supplied

installation

requirements:

• Vent pipes - see requirements, page 15.

• Combustion air pipes - see requirements, page 15.

• Taper-type vent pipe diameter reducers and/or increasers as required.

• Thimble (a thimble is not required if wall is of non-combustible construction).

• Flashing.

• Sheetmetal screws, tape, and sealant as required.

Screened

Exhaust

Assembly,

P/N 53316

Inlet Guard,

P/N 205894

Qty

P/N

Description

1

205883 Complete Horizontal Vent Kit (Same as Option CC6)

1

205885 Concentric Adapter Box Assembly (See FIGURE 13, page 17.)

1

53316 Screened Exhaust Assembly (illustrated below)

1

205894 Inlet Guard (illustrated below)

4

37661 #10-16 x 1/2" long Screws to attach the inlet guard

2

207232 Brackets for attaching Concentric Adapter Box (FIGURE 16B, page 20)

1

53335 Tube of High Temperature (450°F) Silicone Sealant

Installation Instructions

for Horizontal Vent Kit

Option CC6 - Model

SSCBL

1. Determine the location on the outside wall for the vent terminal. Location must

comply with vent length requirements, Requirement No. 4 on pages 15-16. In most

applications, the terminal would be on a level with the heater mounting height. Allow

1/4" per foot (6mm per 305mm) downward pitch for condensate drain.

The distance of the termination of the horizontal vent from adjacent public walkways,

adjacent buildings, openable windows, and building openings must be in accordance

with local codes or, in the absence of local codes, must conform with National Fuel

Gas Code Z223.2. Local codes supersede all provisions in these instructions and in

the National Fuel Gas Code. Minimum clearances for the horizontal vent terminal are

shown below. Also, select a location that complies with adjoining building clearances

as shown in

FIGURE 17, page 21.

Products of combustion can cause discoloring of some building finishes and deteriora-

tion of masonry materials. Applying a clear silicone sealant that is normally used to pro-

tect concrete driveways can protect masonry materials. If discoloration is an esthetic

problem re-locate the vent or install a vertical vent.

2. Install the Vent Pipe and Combustion Air Pipe Runs - Use the type of pipe speci-

fied in Requirement No. 2, page 15. Comply with requirements in Requirement No. 3,

page 15, when attaching pipes to the heater.

Seal all joints. Due to the high temperature,

do not enclose the exhaust pipe or place

pipe closer than 6" (152 mm) to combustible material. Extend the runs close to the wall

location selected in Step 1. Support pipes as required in Requirement No. 6, page 17.

WARNING

All vent terminals

must be positioned

or located away from

fresh air intakes,

doors and windows to

preclude combustion

products from

entering occupied

space. Failure to

comply could result

in severe personal

injury or death and/or

property damage.

Clearances to a

Horizontal Vent

Terminal

Structure

Minimum Clearances for Vent Terminal

Location (all directions unless specified)

Forced air inlet within 10 ft (3.1M)*

3 ft (0.9M) above

Combustion air inlet of another appliance

6 ft (1.8M)

Door, window, or gravity air inlet (any

building opening)

4 ft (1.2M) horizontally

4 ft (1.2M) below

1 ft (305mm) above

Electric meter, gas meter ** and relief

equipment

U.S. - 4 ft (1.2M) horizontally; Canada - 6 ft (1.8M)

Gas regulator **

U.S. - 3 ft (0.9M); Canada - 6 ft (1.8M) horizontally)

Adjoining building or parapet

6 ft (1.8M)

Adjacent public walkways

7 ft (2.1M) above

Grade (ground level)

3 ft (.9M) above***

*Does not apply to the inlet of a direct vent appliance. **Do not terminate the vent directly

above a gas meter or service regulator. *** Consider local snow depth conditions. The vent

must be at least 6” (152mm) higher than anticipated snow depth.