0 controls (cont'd), 8 gas controls (cont'd), Wiring and service – Reznor RPBL Unit Installation Manual User Manual

Page 50: 4 optional electronic modulation (cont'd)

Form I-SSCBL/RPBL, Page 50

Wiring and Service

For wiring, consult the wiring diagram attached to the furnace. All wires in the electrical

box connecting the modulation controls must be 150°C.

This is a unique system which includes custom-built components and custom settings.

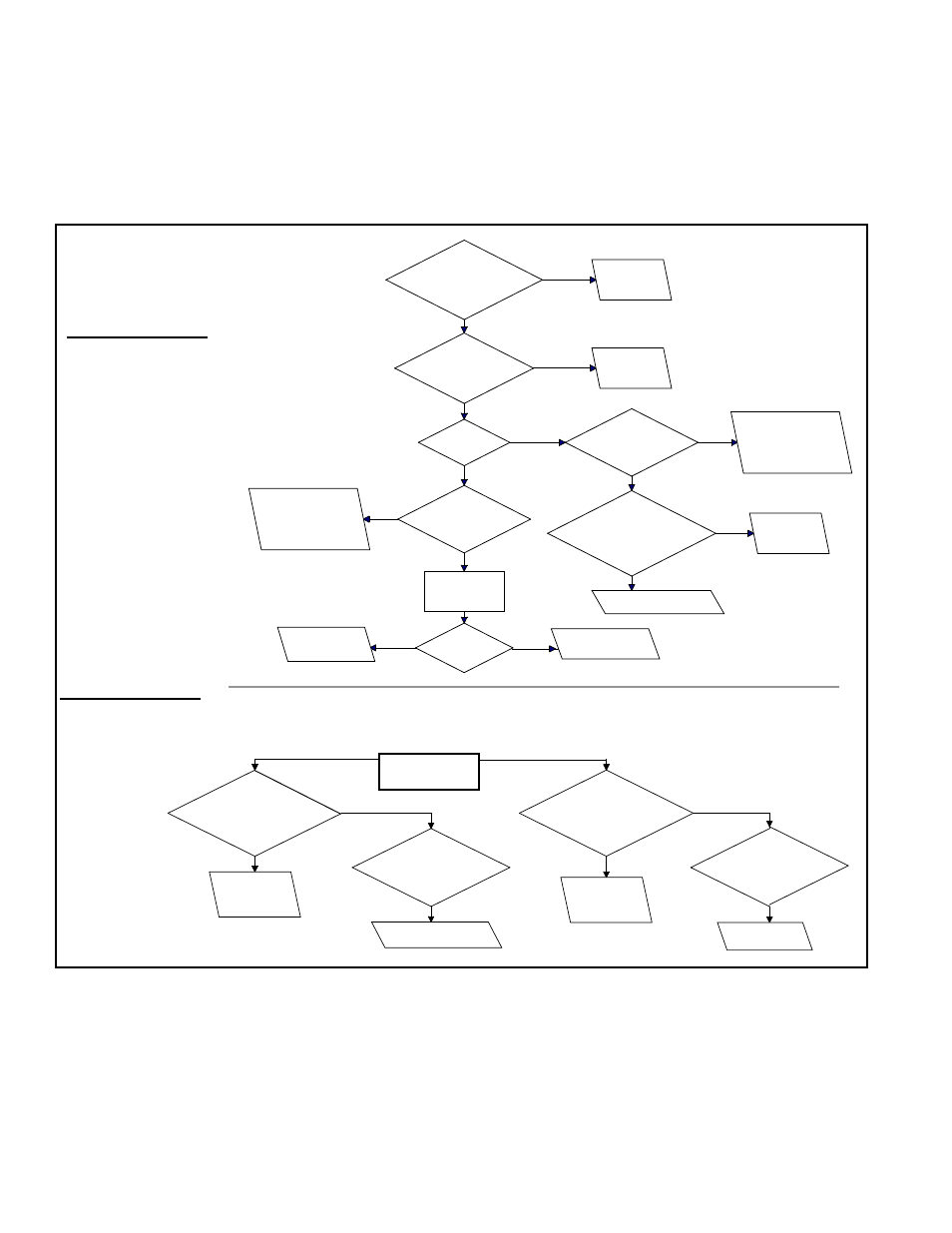

If service is required, follow the general troubleshooting guide and the special trouble-

shooting guide in

FIGURE 52.

Is there 24 volts

between Terminal 2 on #1

Time Delay Relay and

Terminal 7?

Go to

Troubleshooting

Chart for heater.

Is there 24 volts

between Terminal 84 and

Terminal 7?

Is the

damper open?

Is there voltage

between Terminal 88 and

Terminal 7?

Is there voltage

between Terminal 4 on

ignition permissive relay and

Terminal 7?

Replace #1 time delay relay.

Replace ignition

permissive

relay.

Check combustion

damper lower end switch

adjustment. If necessary,

replace end switch.

Is there voltage

between Terminal 87 and

Terminal 7?

Check combustion

damper lower end switch

adjustment. Replace end

switch if necessary.

Place a jumper

across Terminal

86 and Terminal 7.

Did the

damper close?

Replace motor run

time delay relay.

Replace combustion

damper gear motor.

Replace primary

manifold

pressure switch.

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

YES

NO

FIGURE 52 - Troubleshooting Guide

for Checking Bypass Combustion Air

Damper Safety Circuit on units with

Option AG39, AG40, AG41, or AG42

Symptom - Part 1:

Main burners are inoperative.

Assumes that 24 volts is available

between Terminal 2 and Terminal 7.

General

Instructions:

For each step,

check to ensure

that the wiring is

not defective and

that the wiring

connections are

secure.

Computer Controlled

Electronic Modulation

between 25% and 100%

Firing Rate, Option

AG40 and AG42

The furnace functions and is equipped in the same way as for Options AG39 and AG41

except that the temperature settings are selected through field-supplied computer soft-

ware and there is no temperature selector or duct sensor.

The furnace is equipped with a Maxitrol signal conditioner (see

FIGURE 50) which

accepts an input signal of either 4-20 milliamps or 0-10 volts from a customer-supplied

control device such as a computer. With the dip switches on the conditioner in the "on"

positions, the conditioner accepts a 4-20 milliamp signal. In the "off" positions, the con-

ditioner accepts a 0-10V signal. The conditioner converts the signal to the 0 to 20 volt

DC current required to control the modulating valve.

Measure manifold

pressure

during burner cycling.

When the

manifold pressure is

BELOW 1.0" w.c., is there a steady

voltage between Terminal 95

and Terminal 7?

Replace secondary

manifold pressure

switch.

While the

burner is cycling, is

there a steady voltage

between Terminal 84 and

Terminal 2?

Replace the primary

manifold pressure switch.

When the

manifold pressure is

ABOVE 1.5" w.c., is there a steady

voltage between Terminal 95

and Terminal 7?

Replace secondary

manifold pressure

switch.

Is there voltage

between Terminal 4 of the

ignition premissive relay and

Terminal 7?

Replace ignition

permissive relay.

YES

NO

YES

NO

YES

NO

Symptom - Part 2:

Steady call for heat - burner cycles. Assumes that 24 volts is available between Terminals 11 and

7 and Terminals 2 and 7.

8.0 Controls

(cont'd)

8.8 Gas Controls

(cont'd)

Electronic Modulation between 25% and 100% Firing Rate), Options

AG39, AG40, AG41, AG42 (cont'd)

8.8.4 Optional

Electronic Modulation

(cont'd)