0 mechanical (cont'd), 2 venting and combustion air (cont'd) – Reznor RPBL Unit Installation Manual User Manual

Page 16

Form I-SSCBL/RPBL, Page 16

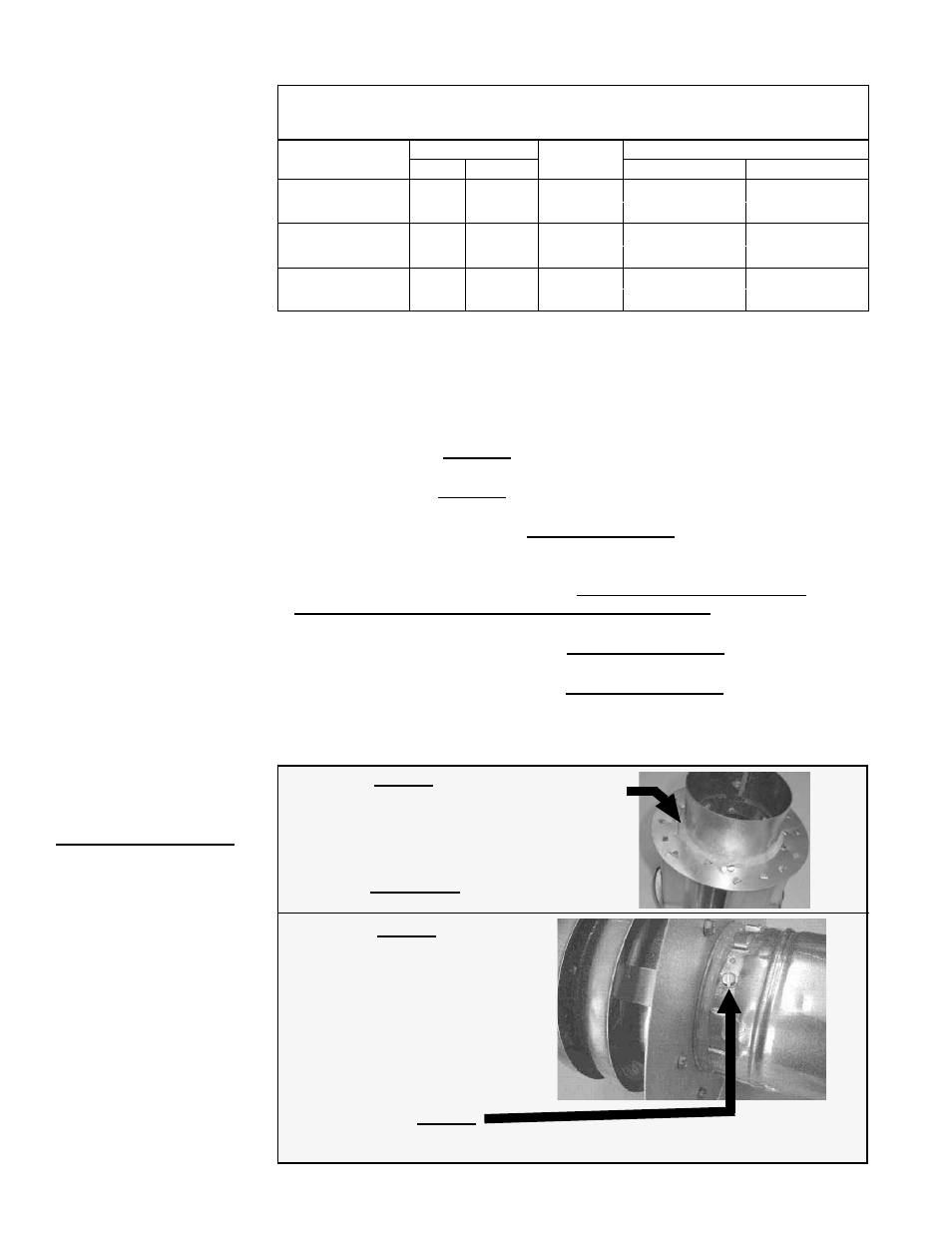

FIGURE 11 - Follow

STEPS to join Double-

Wall (Type B) Pipe and

the Vent Terminal Cap

(horizontal or vertical)

Figure 11 - STEP 1

Place a continual 3/8” bead of silicone sealant

around the circumference of the vent cap collar.

This will prevent any water inside the vent cap

from running down the double-wall pipe.

Do STEP 2 immediately following STEP 1.

Figure 11 - STEP 2

Insert the collar on the vent cap inside

the inner wall of the double-wall pipe.

Insert as far as possible. Add addi-

tional silicone sealant to fully close

any gaps between the vent cap and

the double wall pipe. This is neces-

sary to prevent water from entering

the double wall pipe.

Secure the vent cap to the double-wall pipe by drilling and inserting a 3/4” long

sheetmetal screw into the vent cap collar. Do not overtighten screw.

Figure 11 - STEP 3

(

NOTE: Pipes and vent

caps may not look exactly

as shown in the illustrations.

Instructions apply to both

horizontal and vertical vent

kits.)

6.2.1 Separated-

Combustion Model

SSCBL (cont'd)

6.0 Mechanical

(cont'd)

Maximum Pipe Length from EACH Furnace Section to a Unique

Concentric Adapter Box --

Minimum length is five feet (1.5M).

Model

SSCBL

Pipe Diameter

Maximum

Length

Equivalent Length for an Elbow

Vent

Inlet Air

90°

45°

500, 600

6"

6"

50 ft

8 ft

4 ft

(15 M)

(2.4M)

(1.2M)

400, 700, 800,

1050, 1200

6"

6"

30 ft

8 ft

4 ft

(9 M)

(2.4M)

(1.2M)

All Sizes

7"

7"

70 ft

8 ft

4 ft

(21M)

(2.4M)

(1.2M)

The outside (terminal) portion of the inlet air pipe is 8" in diameter. The 5" I.D. diameter

double-wall vent pipe runs through the 8" inlet air pipe. See

FIGURE 13, page 17. The

outdoor lengths depend on the installation. Outdoor vent length requirements are listed

in the installation instructions for the horizontal and vertical vent/combustion air kits.

5) Joints/Seals

Provide pipe as specified in Requirement No. 2 and make joints as follows:

• If using Category III vent pipe runs, follow the pipe manufacturer’s instructions

for joining and sealing Category III vent pipe sections.

• If using single-wall vent pipe runs, secure slip-fit pipe connections using

sheetmetal screws or rivets. Seal all joints with aluminum tape or silicone sealant.

• To seal joints in the single-wall combustion air pipe, secure slip fit pipe

connections using sheetmetal screws or rivets. Seal all joints with aluminum tape

or silicone sealant.

• To seal joint in the terminal section of double-wall vent pipe (allowed

ONLY ABOVE the concentric pipes on a VERTICAL vent), follow the pipe

manufacturer’s instructions for joining and sealing double-wall vent pipe sections.

• When joining the terminal section of double-wall vent pipe to the vent cap,

follow the illustrated step-by-step instructions in

FIGURE 11.

When joining the terminal section of double-wall vent pipe to a single-wall

or Category III vent pipe run, follow the illustrated step-by-step instructions in

FIGURE 12.

6.2.1.1 Specific

Venting Requirements

(cont'd) (read all before

installing)

4) Pipe Diameter and Length (cont'd)

6.2 Venting and

Combustion Air

(cont'd)