0 maintenance and service, 1 maintenance schedule, 2 maintenance procedures – Reznor RPBL Unit Installation Manual User Manual

Page 54

Form I-SSCBL/RPBL, Page 54

10.0 Maintenance

and Service

WARNING

If you turn off the power supply, turn off the gas. See Hazard Levels,

page 2.

This unit will operate with a minimum of maintenance. To ensure long life and satis-

factory performance, a furnace that is operating under normal conditions should be

inspected every four months. If the furnace is operating in an area where an unusual

amount of dust or soot or other impurities are present in the air, more frequent inspec-

tion is recommended. When servicing, follow standard safety procedures as well as

those specific instructions and warnings mentioned in this manual.

10.1 Maintenance

Schedule

The following procedures should be carried out at least annually (See paragraphs

listed and Paragraphs 10.2.1-10.2.6 for instructions).

Inspect the filters. Clean or replace as needed. See Paragraph 6.3.2.

Check the blowers and belts. Check belts for tension, wear, and alignment. Adjust

or replace as needed. Clean dirt from blower and motor. See Paragraph 6.5.

Check the gas valve to ensure that gas flow is being shut off completely.

Clean the heat exchanger both internally and externally.

Check the pilot burner and main burners for scale, dust, or lint accumulation. Clean

as needed.

Check the vent/combustion air system; inspect all joints. Replace any parts that do

not appear sound.

Check the wiring for any damaged wire. Replace damaged wiring. (See Paragraph

7.0 for wiring requirements.)

CAUTION: When cleaning, wearing eye protection is recommended.

NOTE: Use only factory-authorized replacement parts.

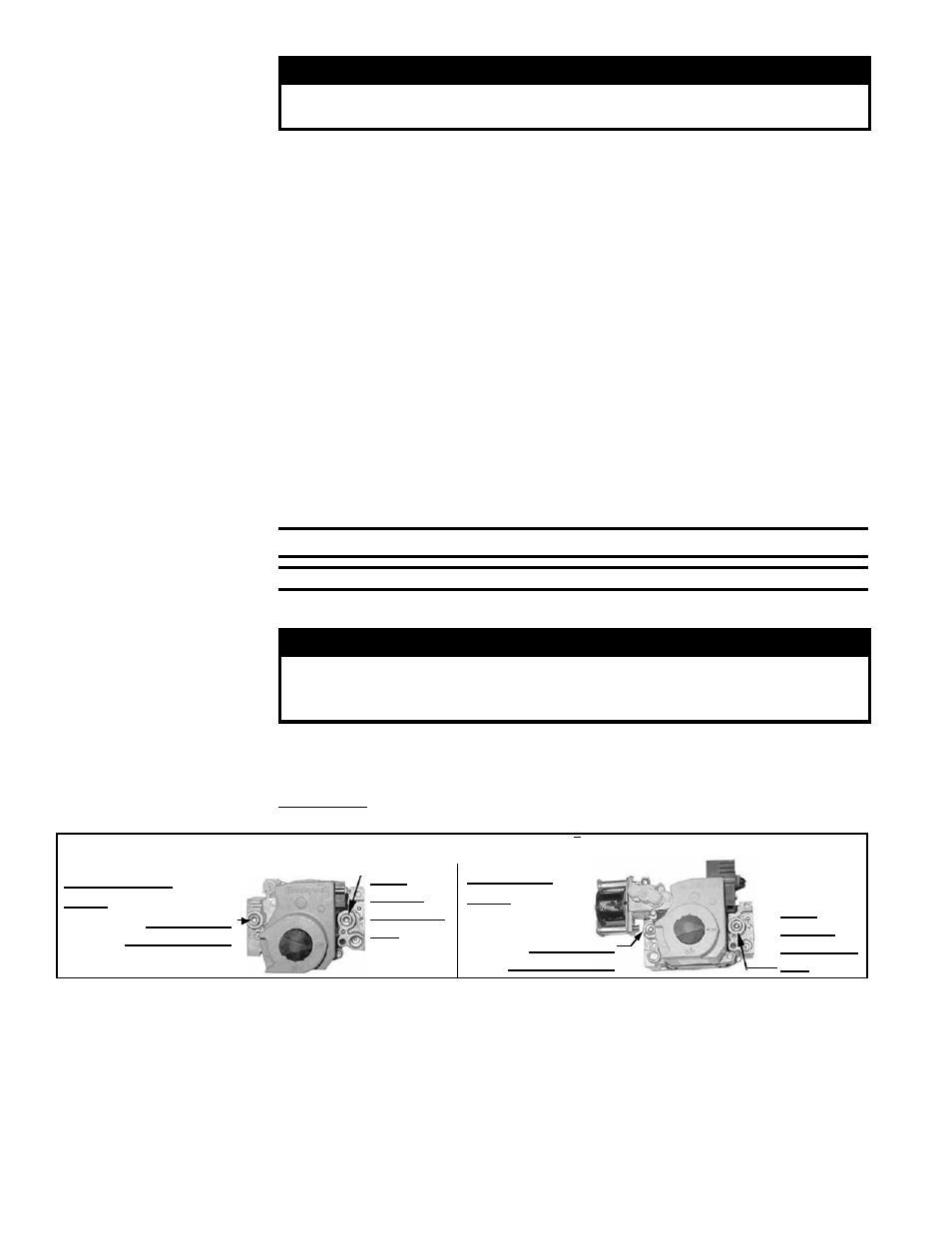

Single-Stage

Valve

Two-Stage

Valve

1/8" INLET

Pressure Tap

1/8”

Outlet

Pressure

Tap

1/8" INLET

Pressure Tap

1/8”

Outlet

Pressure

Tap

FIGURE 57 - Connect manometer to inlet pressure tap to check gas flow shutoff.

2) With the manual valve turned off to prevent flow to the gas valve, connect a

manometer to the 1/8” inlet pressure tap in the valve.

NOTE: A manometer (fluid-

filled gauge) with an inches water column scale is recommended.

3) With the field-installed manual valve remaining closed, observe the manometer

for two to three minutes for an indication of gas pressure. No pressure should be

indicated on the manometer.

If the manometer indicates a gas pressure, the field-installed manual gas valve

must be replaced or repaired before the combination gas valve can be checked.

4) If the manometer does not indicate gas pressure, slowly open the field-installed

manual gas valve. After the manometer's indicated gas pressure has reached

10.2.1. Operating Gas Valve

WARNING

The operating valve is the prime safety shutoff. All gas supply lines must be

free of dirt or scale before connecting to the unit to ensure positive closure.

See Hazard Levels, page 2.

Remove external dirt accumulation and check wiring connections.

The combination gas valve must be checked annually to ensure that the valve is shut-

ting off gas flow completely.

Instructions:

1) Locate the 1/8” FPT INLET pressure tap on the combination valve (FIGURE 57).

10.2 Maintenance

Procedures