4 duct connections - sscbl and rpbl, 0 mechanical (cont'd), 3 unit inlet air (cont'd) – Reznor RPBL Unit Installation Manual User Manual

Page 38

Form I-SSCBL/RPBL, Page 38

FIGURE 40K - Top Filler Panel Installed

Before the top filler

panel is attached,

remove the backing and

adhere the gasket strip

along the bottom of the

outside edge so that

any gaps between the

top filler panel and the

top panel of the furnace

section are sealed.

Filler must be

underneath

the edge of the cooling coil

cabinet top panel

10. The cooling coil cabinet is installed. Follow the instructions provided by the

cooling coil manufacturer to make cooling coil connections.

Cooling Coil

Maintenance

The cooling coil cabinet is designed with easily removable panels on both sides of the

cabinet to provide access for inspection and cleaning. Inspect the coil during routine

maintenance and whenever the filters are changed. Check the cooling coil for build up

of debris; clean as required.

6.4 Duct

Connections

- SSCBL and

RPBL

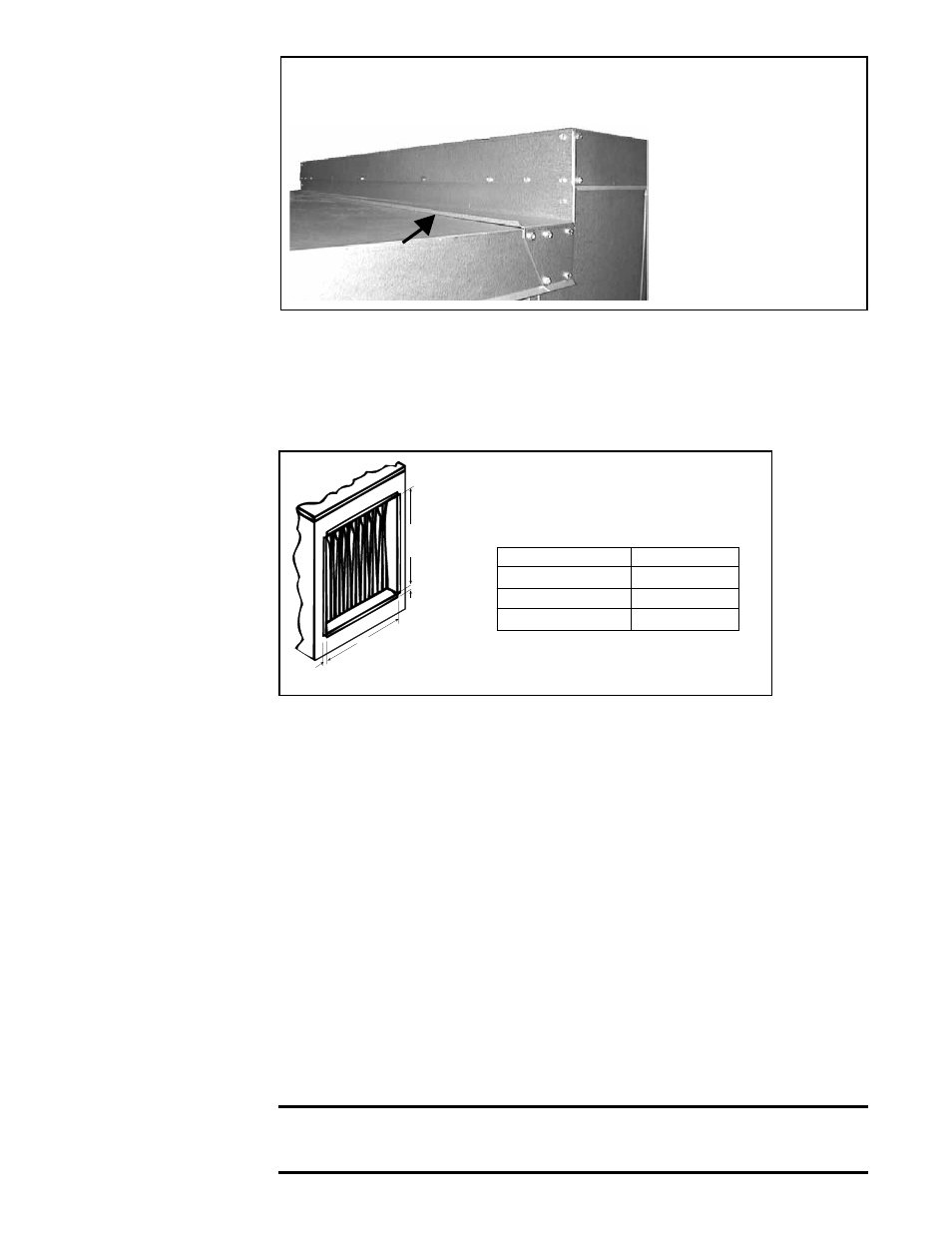

FIGURE 41 - Discharge Duct

Connection Dimensions -

inches (mm)

18

(457mm)

3/4

(19mm)

3/4

(19mm)

G

RPBL, SSCBL

G

500, 600

34-1/2 (876)

700, 1050

40 (1016)

400, 800, 1200

45-1/2 (1156)

Requirements and

Suggestions for

Connecting and

Installing Ducts

• Type of Ductwork - The type of duct installation to be used depends in part on

the type of construction of the roof (whether wood joist, steelbar joist, steel truss,

precast concrete) and the ceiling (whether hung, flush, etc.).

• Ductwork Material - Rectangular duct should be constructed of not lighter than

No. 26 U.S. gauge galvanized iron or No. 24 B & S gauge aluminum.

• Ductwork Structure - All duct sections 24 (610mm) inches or wider, and over 48

(1219mm) inches in length, should be cross broken on top and bottom and should

have standing seams or angle-iron braces. Joints should be S and drive strip, or

locked.

• Through Masonry Walls - No warm air duct should come in contact with masonry

walls. Insulate around all air duct through masonry walls with not less than 1/2" (1"

is recommended) of insulation.

• Through Unheated Space - Insulate all exposed warm air ducts passing through

an unheated space with at least 1/2" (1" is recommended) of insulation.

• Duct Supports - Suspend all ducts securely from adjacent buildings members. Do

not support ducts from unit duct connections.

• Duct Sizing - Proper sizing of the supply air ductwork is necessary to ensure a

satisfactory heating installation. The recognized authority for such information is

the Air Conditioning Contractors Association, 2800 Shirlington Road, Suite 300,

Arlington, VA 22206 (www.acca.org). A manual covering duct sizing in detail may

be purchased directly from them.

CAUTION: An external duct system static pressure not within the limits

shown on the rating plate, or improper motor pulley or belt adjustment,

may overload the motor. See Hazard Levels, page 2.

6.0 Mechanical

(cont'd)

6.3 Unit Inlet Air

(cont'd)

6.3.6 Optional Cooling

Coil Cabinet, Option

AU (cont'd)