5 blowers, belts, and drives – Reznor RPBL Unit Installation Manual User Manual

Page 39

Form I-SSCBL/RPBL, P/N 149159 R7, Page 39

Heater

Duct

Access Panel

in Duct

6

(152mm)

10 (254mm)

1

2

3

4

U Channel

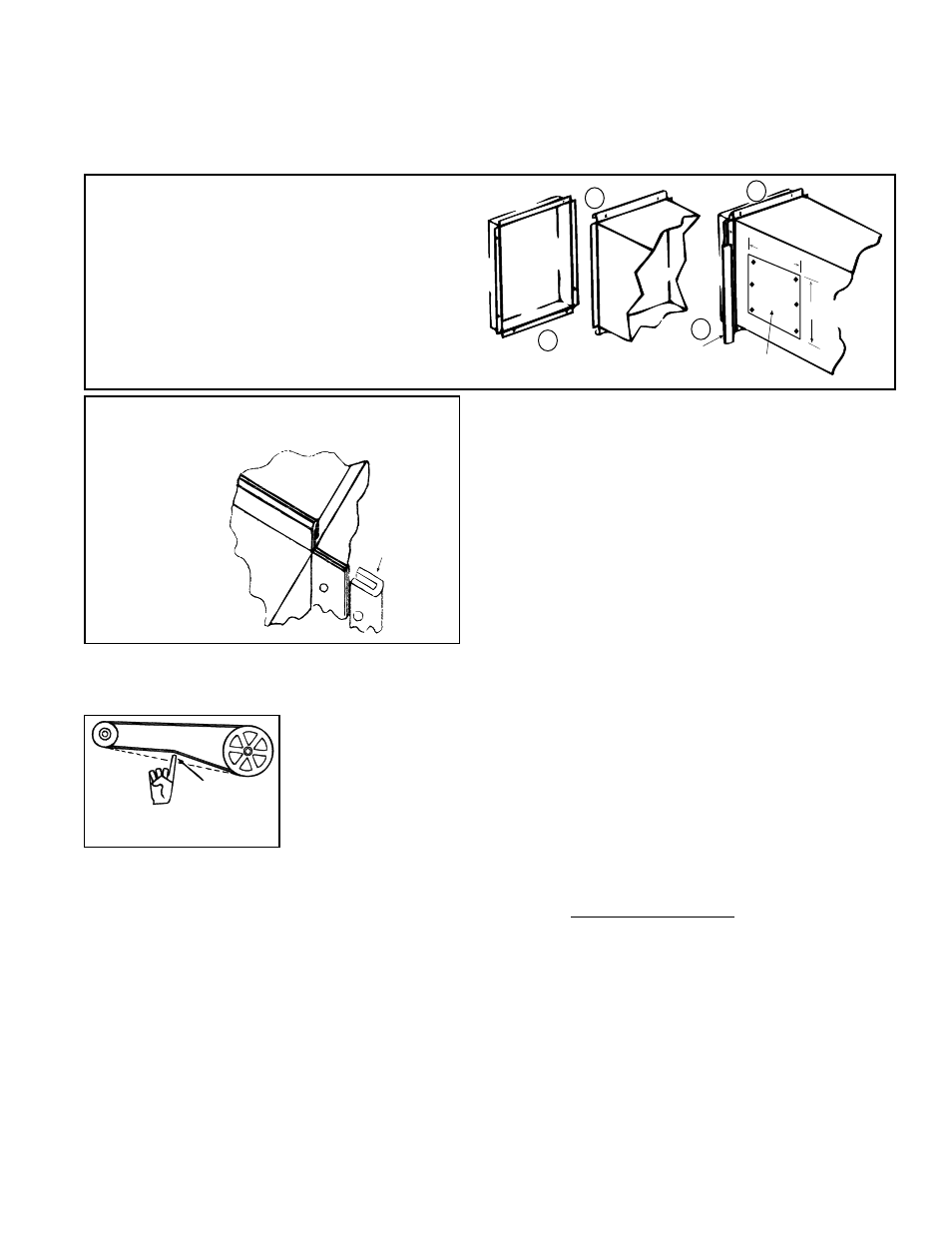

FIGURE 42 - Connecting Supply Air Duct

to the Furnace

(1) Flanges on the furnace (heat exchanger) turn

out as shown.

(2) Shape duct connection as shown -- "U" on top

and bottom; "L" on sides.

(3) Slide "U" channels over furnace top and

bottom flanges making connection.

(4) Form "U" channels to seal sides. Drill and lock

with sheetmetal screws.

• Removable Panels (See FIGURE 42.). - The ducts should have removable

access panels. These openings must be accessible when the furnace is in service

and should be a minimum of 6" x 10" (152mm x 254mm) in size so smoke or

reflected light may be observed inside the casing to indicate the presence of leaks

in the heat exchanger. Attach the covers for the openings in a manner that will

prevent leakage.

•

Horizontal Discharge Duct Length - A minimum

horizontal duct run of 24" (610mm) is

recommended

before turns or branches are made in the duct system to

reduce losses at the furnace outlet.

•

Supply Air Duct/Furnace Horizontal Connection -

The seal between the furnace and the duct must be

mechanical. Duct connection should be made with "U"

type flanges on the top and bottom of the connecting

duct. Slide the duct over the flanges of the heater giving

an airtight fit. Provide "U" type channels for the side

flanges to ensure tight joints. Use sheetmetal screws to

fasten ducts and "U" channels to the furnace flange. See

FIGURE 43.

FIGURE 43 -

Install "U"

Channel on

Sides of Duct

Connection

Furnace

Duct

U Channel

of Light

Gauge Metal

6.5 Blowers, Belts,

and Drives

3/4

(19mm)

FIGURE 44 - Check

Belt Tension

Check belt tension. Proper belt tension is important to the long life of the belt and

motor. A loose belt will cause wear and slippage. Too much tension will cause exces-

sive motor and blower bearing wear. Adjust the belt tension by turning the adjusting

screw on the motor base until the belt can be depressed 3/4" (19mm). (See

FIGURE

44.) After correct tension is achieved, re-tighten the locknut on the adjustment screw.

Be sure that the belt is aligned in the pulleys.

Adjusting Blower Speed

The system is set at the factory for the RPM required to meet the CFM and external

static pressure specified on the order. If estimated external static pressure is incorrect,

or changes were made to the duct system, the blower RPM may have to be adjusted.

Motors are equipped with adjustable pitch pulleys which permit adjustment of blower

speed.

To make adjustments to units with less than a 5HP motor, follow these instruc-

tions.

1. Turn off the gas and the electric power.

2. Loosen belt tension and remove the belt.

3. Loosen the set screw on the side of the pulley away from the motor.

4. To increase the blower speed, decreasing outlet temperature, turn the

adjustable half of the pulley inward.

To decrease the blower speed, increasing

the outlet temperature, turn the adjustable half of the pulley outward. One turn of

the pulley will change the speed 8-10%.

5. Tighten the set screw on the flat portion of the pulley shaft.

6. Replace the belt and adjust the belt tension. Adjust tension by turning the

adjusting screw on the motor base until the belt can be depressed 3/4". (See

FIGURE 44.) Re-tighten the lock nut on the adjusting screw. Be sure that the belts

are aligned in the pulley grooves properly and are not angled from pulley to pulley.