0 controls (cont'd), 8 gas controls (cont'd) – Reznor RPBL Unit Installation Manual User Manual

Page 48

Form I-SSCBL/RPBL, Page 48

Size

Maximum

Turndown

MBH Input

Range

Inlet Pressure to Modu-

lating Valve (factory set)

Gas Supply

Pressure Required

400

25%

100-400

4.4" w.c.

6" w.c.

500

28%

69-250

4.0" w.c.

5" w.c.

600

23%

69-300

4.0" w.c.

5" w.c.

800

25%

100-400

4.4" w.c.

6" w.c.

1200

25%

100-400

4.4" w.c.

6" w.c.

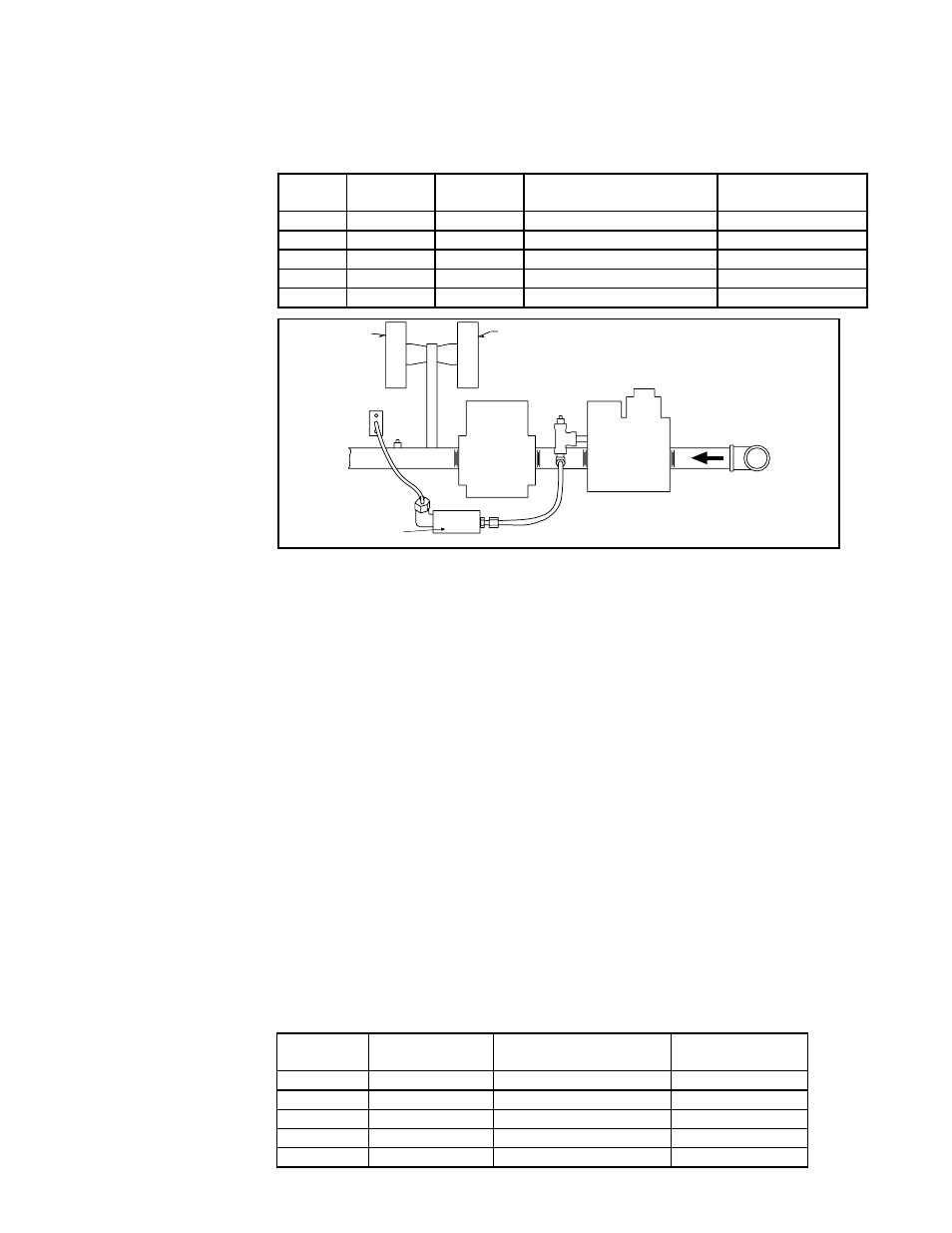

Carryover

Regulator

P rimary Gas

Flow Pressure

Switch

White Label

1.1 w.c.

Gas Flow

Pressure Switch

White Label

1.1 w.c.

Modulating

Valve

Single-Stage

Gas Valve

FIGURE 51 - Manifold

Arrangement on

Furnace with Optional

Electronic Modulation

between 25-100% Firing

Rate

Note: Arrangement may vary slightly depending

on gas valve; components are the same.

The gas train (

FIGURE 51) in a furnace with this type of electronic modulation control

includes a single-stage gas valve, a modulating valve, and two gas pressure switches.

The burner rack is equipped with one flash carryover and a regulated gas lighter tube

system. The carryover lighter tube receives its gas supply through the regulator, simul-

taneously with the gas to the burner. Control of the system is through a Maxitrol ampli-

fier with a corresponding remote temperature dial.

Description of

Operation - furnace

with Option AG39,

AG40, AG41 or AG42

Combustion Air

Pressure Switch

Setting

This uniquely designed modulation system requires combustion air pressure settings

different from the standard system. The approximate settings for the combustion air

proving switch at sea-level operation are shown in the table.

w/AG 39,

40, 41, 42

Startup Cold

Equilibrium at Full

Rate

Factory Setting

400

-1.2"w.c.±0.2

-0.95"w.c.±0.1

-.75"w.c.±0.5

500

-1.2"w.c.±0.2

-0.95"w.c.±0.1

-.75"w.c.±0.5

600

-1.2"w.c.±0.2

-0.95"w.c.±0.1

-.75"w.c.±0.5

800

-1.2"w.c.±0.2

-0.95"w.c.±0.1

-.75"w.c.±0.5

1200

-1.2"w.c.±0.2

-0.95"w.c.±0.1

-.75"w.c.±0.5

8.0 Controls

(cont'd)

8.8 Gas Controls

(cont'd)

8.8.4 Optional

Electronic Modulation

(cont'd)

Electronic Modulation between 25% and 100% Firing Rate), Options

AG39, AG40, AG41, AG42 (cont'd)

The furnace with this type of electronic modulation will ignite at any input rate in the

available range and will maintain average thermal efficiencies equal to or greater than

the thermal efficiency at full fire. The following table applies to the furnace with the

manifold illustrated in

FIGURE 51.

The gas supply (6" w.c. required) connects to the single-stage gas valve. To compen-

sate for additional pressure loss through the modulating valve, the single-stage gas

valve has a custom outlet pressure setting higher than when it is used on a standard

gas manifold. The pilot tubing connects to the pilot port on the single-stage gas valve.

When the valve receives a call for heat from the amplifier and pilot is established, gas

flow from the single-stage valve goes to both the modulating valve and the regulated

lighter tube system.

When the signal from the amplifier to the modulating valve

requires less-than-high fire operation, the modulating valve functions to lessen the

gas flow to the burner to reduce the input rate to that required to maintain the desired

temperature. When the input rate is reduced enough to decrease the gas pressure to

1.1" w.c., the primary gas pressure switch in the manifold activates the gear motor that

controls the bypass damper in the venter/combustion air system. The bypass damper

opens diverting some of the incoming air directly into the flue duct, reducing airflow

through the burner. Safety switches monitor the position of the bypass damper. When

the gas pressure increases above 1.1" w.c., the bypass damper closes.