AERCO SmartPlate User Manual

Page 97

SmartPlate Installation, Operation & Maintenance Manual

APPENDIX A – MODBUS CONTROL AND COMMUNICATION

OMM-0069_0E

AERCO International, Inc.

100 Oritani Dr. Blauvelt, NY 10913

Page 97 of 138

SP-100

Phone: 800-526-0288

PRI: 11/26/2013

A.2 MODBUS COMMUNICATION INFORMATION

NOTE

The Eurotherm 2400 Controller supports the MODBUS RTU mode

of transmission. The default settings are as follows: 9600 Baud

Rate, one start bit, eight data bits, one stop bit, & no parity bit.

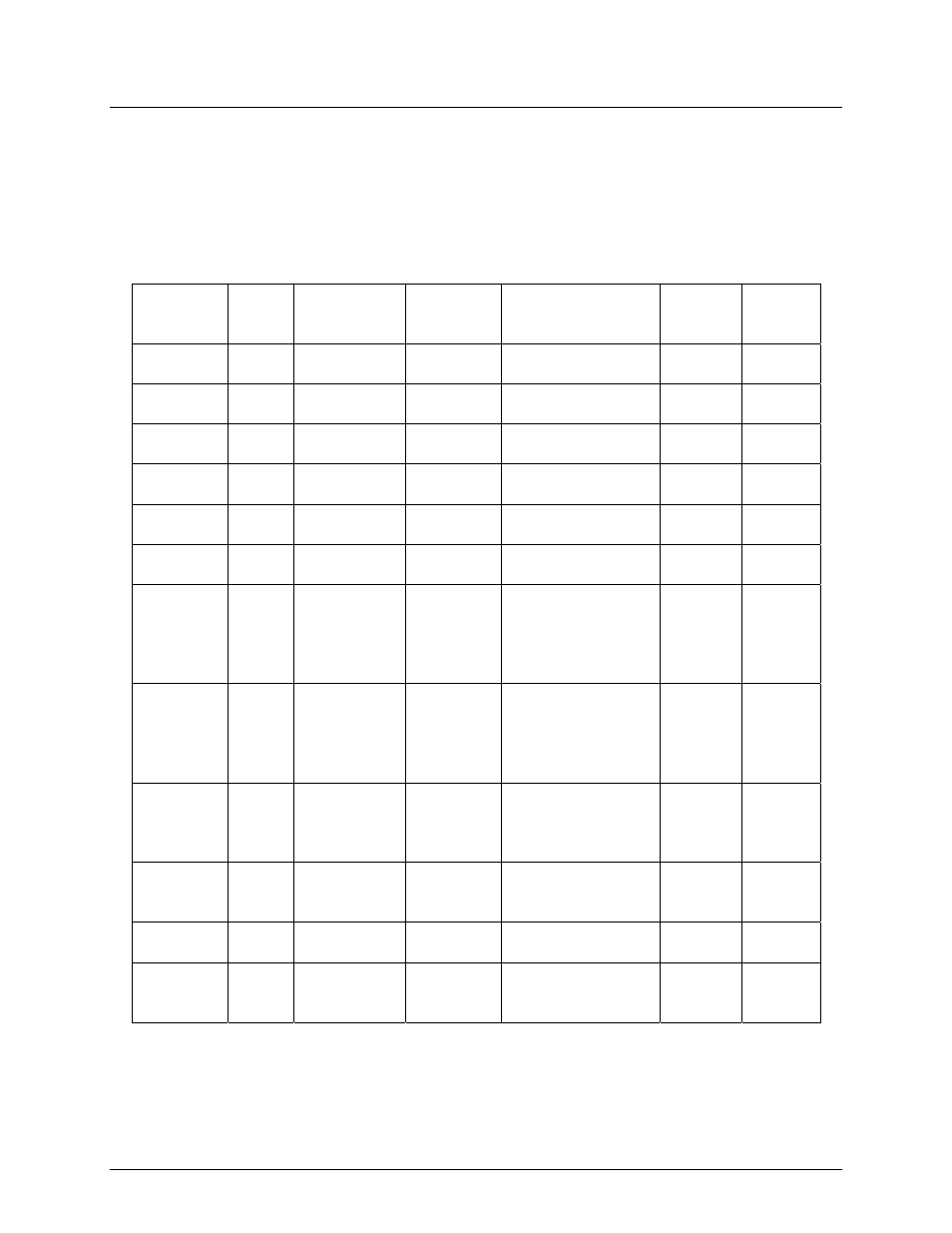

EUROTHERM SERIES 2400 CONTROLLER MODBUS POINTS

MODBUS

Data

Address

Menu

Item

Menu Item

Description

Units &

Range

Default/Comments

Register

Type

Ref. 1

Comm.

Guide

5 w.SP

Setpoint

40-205°F

140°F, Address to

read value

Read

Only

5-4

24 SP

1

Setpoint

40-180°F

140°F, Address to

change value

Write 5-11

1

Top

Value

Outlet Temp

40-205°F

Same value as

front display

Read

Only

5-3

133 LoGH

Peak

Temp

40-205°F

Resets on Power

Loss

Read

Only

5-15

135 LoGA

Average

Temp

40-205°F

Resets on Power

Loss

Read

Only

5-15

134 LoGL

Low

Temp

40-205°F

Resets on Power

Loss

Read

Only

5-15

13 (set)

74

(status,

0 = safe

1 = alarm)

AL 1

Over Temp

Alarm

40-205°F

20°F above

setpoint; Alarm

Type 17:

Deviation High

Read

Only

5-7

5-20

14 (set)

74

(status,

0 = safe

1= alarm)

AL 2

(FSH)

Full Scale

High Alarm

205°F

205 ° F

Alarm Type 2:

Full Scale High

Read

Only

5-7

5-20

258 Sbr

Feedback

Sensor

Break

Status:

0: Good

1: Failed

Denotes

Feedback Sensor

Failure/Open

Circuit

Read

Only

5-18

289 Li

1

Feedback

Sensor

Temp

40-180°F

Sensor input to

controller, same

as display temp.

Read

Only

5-14

290 Li

2 Flow GPM

Read

Only

5-14

3 OP

Control

Output

Signal

%

Correlates to

valve position

Read

Only

5-4

REFERENCE DOCUMENTS

:

1. Eurotherm 2000 Series Communications Handbook, # HA026230

2. Eurotherm 2404/2408 Control Setpoint Programmer Installation and Operation

Handbook, # HA025132